Precision engineering has become a cornerstone in the modern manufacturing landscape, especially in the production of functional and durable components like drawer slides. These small yet essential mechanisms play a critical role in the furniture and cabinetry industries, where smooth motion, stability, and longevity are paramount. With consumers and manufacturers alike demanding higher quality, the emphasis on precision in the manufacturing of drawer slides has never been more pronounced.

Understanding Precision Engineering

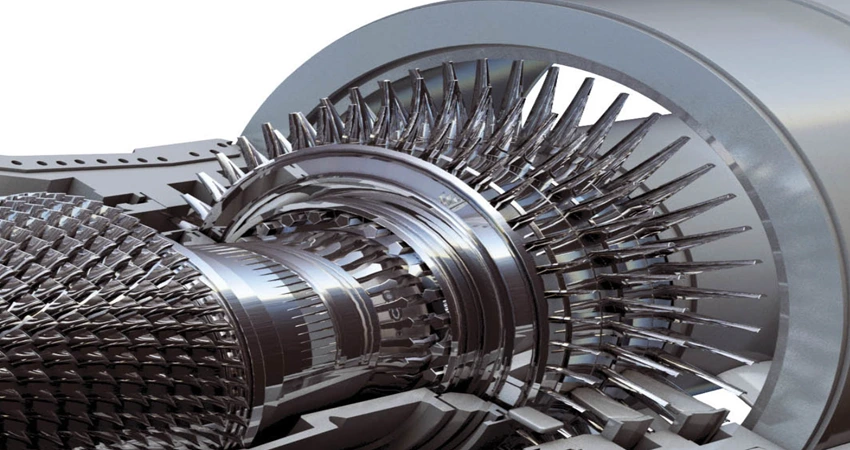

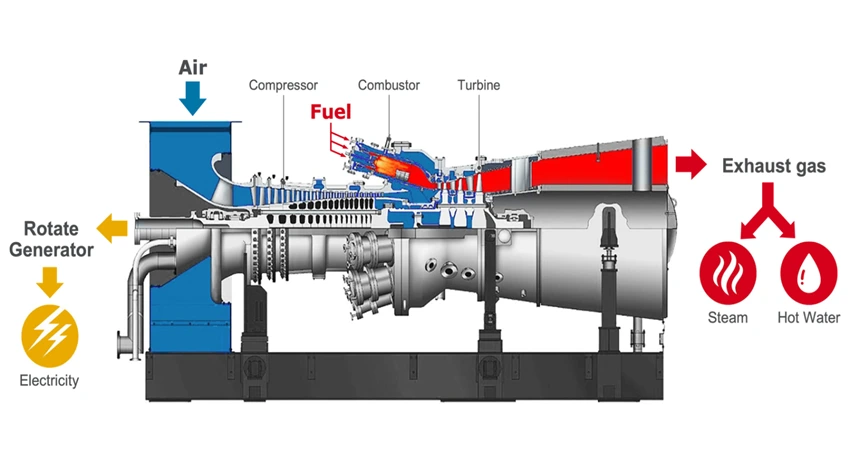

Precision engineering refers to the meticulous design and manufacturing of components with tight tolerances and high accuracy. It involves the use of advanced technologies, computer-aided design (CAD), and computer-aided manufacturing (CAM) systems to ensure every part is produced to exact specifications. This approach reduces variability, increases efficiency, and results in components that perform consistently over time.

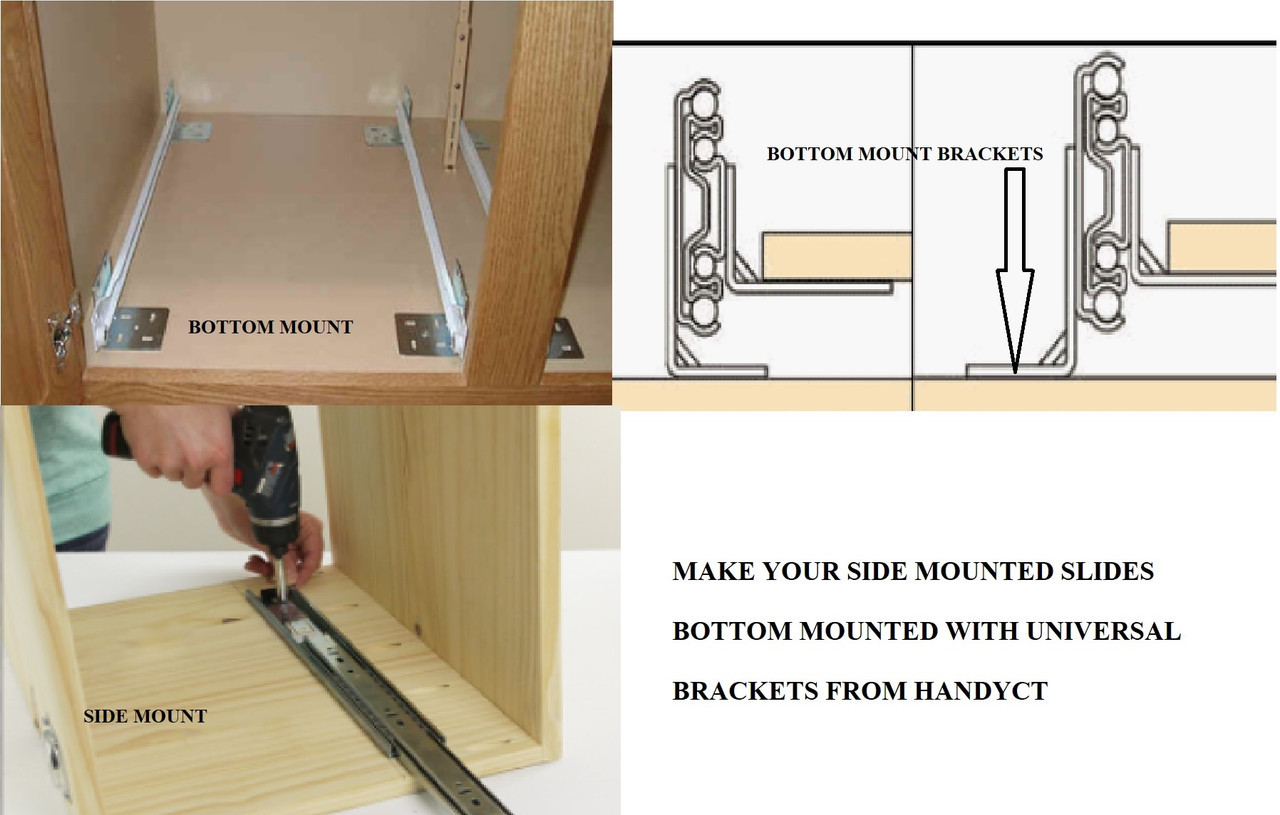

In drawer slide manufacturing, precision engineering ensures that each slide aligns perfectly with its corresponding track, allowing for seamless opening and closing. This is particularly important in modern furniture design, where aesthetics and functionality are equally important. Consumers expect drawers to glide silently and effortlessly, and any deviation from precision can compromise the user experience.

The Role of a Reliable Drawer Slides Manufacturer

Choosing the right Drawer Slides Manufacturer is essential to ensure product quality and consistency. Manufacturers that employ precision engineering techniques are better equipped to meet the demands of both residential and commercial furniture applications. These companies invest in state-of-the-art machinery, rigorous quality control protocols, and skilled labor to ensure each slide functions flawlessly.

For example, CNC (Computer Numerical Control) machines are widely used in the production of drawer slides to guarantee precision in dimensions, holes, and bending angles. Laser cutting and robotic welding further enhance the quality and durability of the final product. By adopting these methods, a reputable manufacturer can produce drawer slides that offer long-term reliability, even under frequent or heavy use.

Importance of Material Selection

Precision engineering goes hand in hand with the careful selection of materials. Drawer slides must withstand constant use, bearing weight while maintaining their structural integrity. High-quality materials such as cold-rolled steel, stainless steel, and aluminum alloys are commonly used. These metals provide the necessary strength and resistance to corrosion.

Additionally, surface treatments like electroplating or powder coating are applied to improve wear resistance and enhance the appearance of the slides. With the help of precision engineering, these treatments are uniformly applied, contributing to both the functionality and the aesthetic value of the finished product.

Innovation and Customization

The increasing demand for customized furniture solutions has prompted manufacturers to develop tailored drawer slide options for specific applications. Whether it’s soft-close, push-to-open, or heavy-duty models, precision engineering enables the creation of diverse product lines without sacrificing quality.

Customization also involves varying lengths, load capacities, and extension types (such as full-extension or three-quarter extension). By using computer-aided modeling and testing, manufacturers can simulate real-world scenarios to fine-tune the design before full-scale production. This not only speeds up the development process but also ensures that the product will meet customer expectations upon release.

Quality Control and Testing

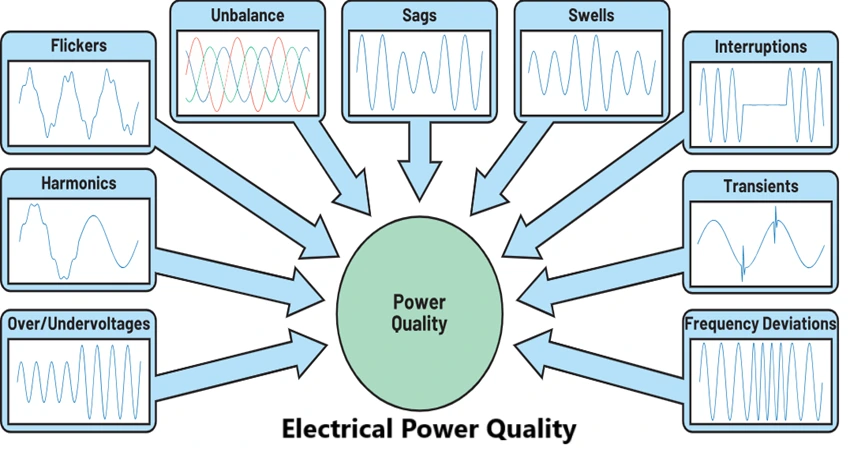

Another essential aspect of precision engineering in drawer slide manufacturing is quality control. Advanced inspection tools like coordinate measuring machines (CMMs) and optical scanners help manufacturers detect even the slightest imperfections. These tools measure dimensions with micron-level accuracy, allowing for prompt corrections before the product reaches the end-user.

Each batch of drawer slides typically undergoes rigorous testing for load-bearing capacity, cycle durability, and corrosion resistance. This ensures that the final product can perform reliably over thousands of open-close cycles, providing value and peace of mind to customers.

Environmental Considerations

Modern precision engineering also takes sustainability into account. Efficient manufacturing processes reduce waste and energy consumption. Manufacturers that adopt green practices, such as recycling metal scrap and minimizing the use of harmful chemicals, contribute positively to the environment without compromising product quality.

Moreover, durable and long-lasting drawer slides reduce the need for frequent replacements, lowering the overall environmental impact. Consumers are increasingly favoring products from companies that prioritize both performance and sustainability.

Conclusion

Precision engineering has revolutionized the drawer slide manufacturing industry by ensuring superior performance, reliability, and customization. From material selection and advanced machinery to stringent quality control and sustainability initiatives, precision plays a vital role at every stage of production. Selecting a skilled and technologically advanced Drawer Slides Manufacturer is essential for any business or individual looking to achieve excellence in furniture design. As consumer expectations continue to rise, the value of precision in this niche manufacturing sector will only grow stronger.