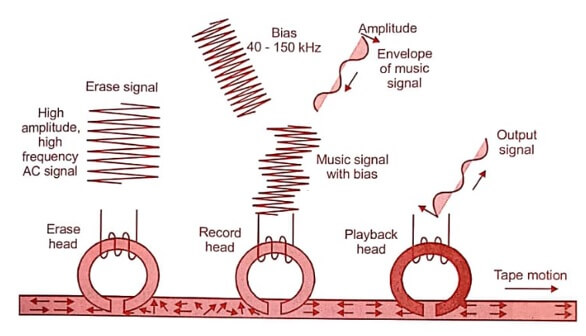

Fig 1.1

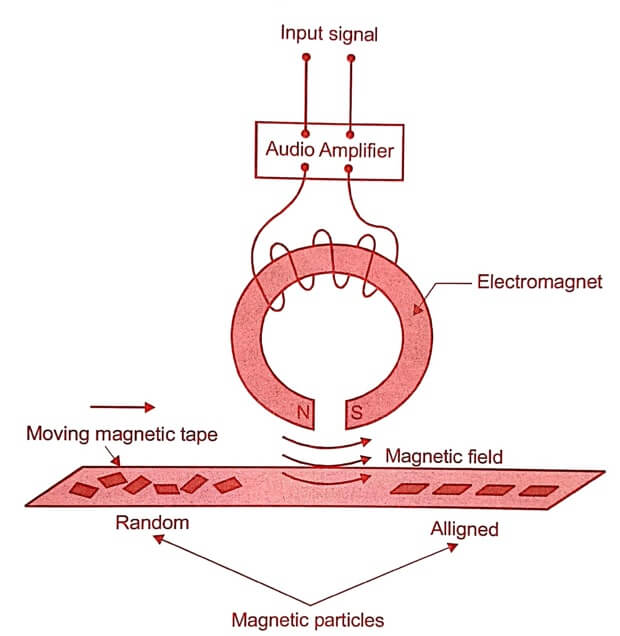

Magnetic recording materials involves the storage of data using a magnetic medium. The data is in the form of analog or digital format.

Audiocassette tape recorders are widely used to record and play back music or speech. Information is stored on a narrow ribbon of plastic tape that has one side coated with a magnetic material consisting of magnetically active particles, most commonly iron oxide and chromium dioxide. As the tape passes around the magnetic heads of a tape recorder, sound is recorded, replayed, or erased according to the heads that are activated.

A recording head (a small electromagnet) magnetizes the passing tape in such a way that the magnetic particles on it are realigned in a pattern that corresponds to the loudness and frequency (rate of vibration) of incoming sounds. The resulting pattern remains on the tape until erased or changed.

The playback head contains a coil of wire. When the magnetized tape moves past the coil, an electrical current is created.

The current will alternate in direction depending on the alignment of the magnetic particles as they pass by the playback head. The magnetic pattern originally recorded on the tape is transformed into a precisely corresponding electrical signal. The electric current from the playback head is then amplified and sent to an audio speaker.

The following four points are used to design and manufacturing the magnetic heads to read and write for data storage.

- An electric current produces a magnetic field, when it flows through a wire.

- In soft magnetic materials, the electrical resistance changes when the material is magnetized and when the magnetizing filed is switched off then the resistance returns to its original value. This is called Magneto – resistance effect [or] MR effect.

- If large changes in electrical resistance with magnetization occurs and it is called Giant – magneto resistance effect [GMR effect]

- In hard magnetic materials, once it is magnetized they do not loss the magnetization even when the field is switched off.

Magnetic Recording Materials

- In the magnetic storage devices the Ferromagnetic and Ferrimagnetic materials [ferrites] are used.

- Iron oxide, chromium oxide, barium ferrite are the magnetic materials used as storage media.

- In magnetic bubble storage Ni-Fe alloy, yttrium iron Garnets, orthoferrites, hexaferrites and rare earth metals are used.

- A magnetic material should have high permeability for easy magnetization in it.

- When we apply a magnetic field in a ferromagnetic, or ferrite, the magnetic moments are induced, due to this we can record the information.

We have different types magnetic storage devices.

-

- Magnetic tapes

- Floppy disk

- Hard disk memory

- Magnetic bubble materials.

Magnetic tapes

- Magnetic tape consists of magnetic emulsion such as a thin layer of iron oxide or chromium oxide or cobalt – modified iron oxide magnetic medium on a thick polymeric substrate.

- Polymeric substrate made of Poly Ethylene Terephalate (PET) or Dupont or Mylar film.

- Now days polyester films are used. Since it is highly resistant to oxidation and hydrolysis.

- The magnetic layer consists of a binder (Jello-o), to fix the magnetic materials on the film.

- In addition to a lubricant, a cleaning agent, and carbon black are mixed with binder.

- Then the magnetic tape is wounded and forming a tape pack.

- For audio and video recordings the frequency modulation (FM) recording is used to get high fidelity and high band width.

- In computers, the digital tape recording units are used as storage devices.

- In the digital recorder, the tape moves at a constant speed and more than million of bits are recorded per second.

Non – Return to zero [NRZ] recording system

- In this system, the tape is magnetically saturated at all times either in the positive or in the negative direction.

- The NRZ method uses the change in flux direction on the tape to indicate a 1 – bit and no change in flux direction on the tape as 0 – bit.

- The recording head is a electromagnet made of soft iron with a small gap.

Recording, Reading and Erasing

Recording

- Initially a signal current is produced which is the combination of the music signal and bias current of 40 – 150kHz.

- When signal current is passing through the coil of the record head and produces magnetic flux through the gap, and induced on the tape.

- When the tape is moved across the record head gap, the magnetic material on the tape is subjected to a flux pattern proportional to the signal current.

Reading or Reproducing

- The magnetic pattern on the tape is read by moving the tape across a reading head or playback head.

- The reading head is similar in construction of the recording head.

- The magnetic tape induces a voltage in the head, which is proportional to the rate of change of magnetic flux and reproducing the original output signal.

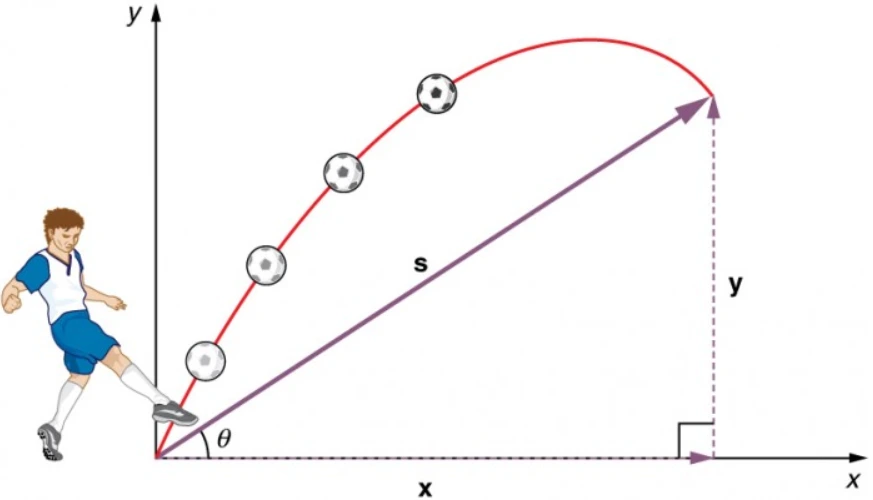

Fig 1.2

Erasing

The erasing of data or music can be done by using a erase signal which is a high amplitude, high frequency AC signal. This erase signal destroys the alignment of the magnetic patterns.

Magnetic floppy disk

- It is a direct access storage device. This magnetic storage medium introduced by IBM in 1971.

A small magnetic disc is sandwiched by a plastic covering. This is where data is stored and read from. A read/write head on the drive will manipulate data on the floppy disc.

- Magnetic disk is made up of flexible plastic material (mylar) coated on both sides with a magnetic material (Iron oxide).

- The data is written by creating a magnetic flux Pattern corresponding to the values of signal current pulses.

- Computer data are organized into a number of concentric circular tracks. Each track is designated with a location number.

- There are 200 to 800 tracks. ( 1cm = 236 tracks ) in 3.5″ disc.

- There is a Read – write head. It is a small electromagnet with a minute gap between the poles.

- In the writing operation the disk moves over the gap, the electric pulses from CPU flow through the write coil of head. This causes the iron oxide coating to be magnetized in the proper pattern.

[ie, Electrical energy → magnetic energy] - For the reading operation, the magnetized pattern induces the pulses of current in the data into the read coil that sends the data into the CPU.

- Data can be stored on both sides of the floppy disk.

- It is a non – volatile storage medium.

- It is properly covered by hard plastic material.

- There are write protect notch, index hole, drive spindle hole, and R/W slot.

- Available sizes: 8 inch, 5¼ inch and 3 ½ inch.

Figure.1.3. Schematic diagram of Floppy disc

Reading and Writing the data

In floppy disk, reading and writing the data is almost to be the same. The following will explain how a floppy disk read/writes:

The computer will pass down a command to the computer hardware to record a data file on the floppy disk. The motor in the diskette drive will now begin to spin the floppy disk.

The disc contains many concentric tracks on each side and divided into smaller segments called sectors.

A stepper motor will make its rotation that will correspond to the spacing between the tracks. Access time is the time taken to obtain the correct track.

The read head will verify the prewritten address on the formatted floppy disk to ensure that it is using the correct side and it is on a right track. Before the data is being stored to the floppy disk, an erase coil will tend to ‘remove’ a wide, and the ‘clean array’ sector subsequent to the recording the sector data with the write head.

The write head place data on the floppy disk by attracting minute, iron, bar-magnet particles implanted in the diskette surface. The magnetized particles will cause their pattern to be detected and read on a following read operation. After that, the diskette will stop spinning and waits for the next command.

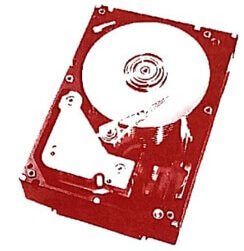

Hard disk memory

Hard disks are known as Winchester disks. These hard disks are the most important permanent storage used in PCs.

The hard disk contains one or more flat disks to store the data in the drive. These disks are called platters. It is made of hard aluminium and coated with magnetic oxide and the platter is built into a box. Similar such disks are mounted on a vertical shaft forming a disk pack.

The surfaces of each platter are treated to remove any imperfections and the hard disk is assembled in a clean room to avoid from dust particles.

Fig. 1.4. Hard disk with 10 stacked platters

Today’s hard disks use thin film media. The thin film media consists of a very thin layer of magnetic material applied on the surface of the platters. Many methods like electroplating and sputtering (vapor deposition process) to deposit a thin layer of magnetic material on the surface. Compared to oxide media, thin film media is much more uniform and smooth. It also has greatly superior magnetic properties, allowing it to store more data in the same amount of space. Finally, it’s a much harder and more durable material than oxide, and therefore much less chance to damage.

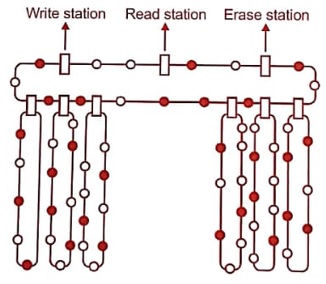

Magnetic bubble Materials

- Magnetic bubble is the direct access storage medium.

- Magnetic bubbles are soft magnetic materials with magnetic domains of a few micrometer in diameter.

- These bubbles are the electric analogue of the magnetic disk memories used in computers.

- The magnetic disk in the hard disk memory is moved mechanically where as the bubbles in a bubble memory device are moved electronically at very high speeds.

- So the read out time or storing time is greatly reduced in bubble memory device.

- The bubble units are made with solid state electronic chips.

- A magnetic bubble can be thought of as a positively charged is land in a sea of negatively charged magnetic film.

- The presence of a bubble is an ‘ON’ condition and the absence of a bubble is an ‘off’ condition. [ie 1 or 0 ].

- Figure shows the schematic diagram of a magnetic bubble memory. It consists of one major loop and 157 minor loops. Each minor loop has 641 bubble sites.

Presence of a bubble.

Absence of a bubble.

Fig 1.5

Writing Operation

When a data has to be stored, the bubbles from the minor loops are transferred to the major loop, and it goes to the write station. In write station the data is entered and the bubble again comes to minor loop.

Reading Operation

To read the data from the storage, the bubble from minor loops are transferred to the major loop and it goes to the read station, then it comes to the minor loop.

The data can be altered by the erase station, it we need to erase it.

Advantages

- It is non – volatile.

- It has high storage capacity than the magnetic hard disk.

- It has high access speed.

Materials used for magnetic bubbles

- Yittrium Ion Garnet [YIG]

- Hexa – Ferrites

- Amorphous rare earth metals

- Orthoferrites

Construction

A Bubble memory consists of materials such as magnetic garnets and store the data as microscopic magnets. A thin film of these garnets are deposited on a non – magnetic substrate of Gadolinium Gallium Garnet in Integrated Circuit [IC] form.

| Read More Topics |

| Hard and soft magnetic material |

| Basic definitions of magnetic materials |

| Classification of ferromagnetic materials |