Filled systems temperature is by expansion of gases and liquids when it is heated and contraction of the same when it is cooled.

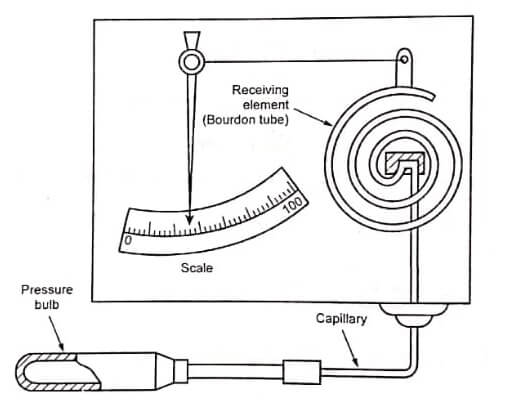

Fig shows a filled systems. The pressure bulb contains thermometer fluid. This is connected to a receiving element by a capillary. The bulb is kept in the place where temperature is to be measured. Because of temperature, the fluid expands, resulting in the expansion of the receiving element. This causes the pointer to move over a calibrated scale which directly gives the temperature reading.

Bimetallic Strip

The bimetallic strip temperature measurement is based on change in dimension of the metal. A very widely used method of temperature measurement is the bimetallic strip. As already discussed, the basic principle in bimetallic temperature measurement is based on the change in dimension of metals i.e., expand or contract when there is a change in temperature.

The expansion or contraction is based on the thermal expansion coefficient. It changes from metal to metal.

Working:

Two pieces of metal with different coefficients of thermal expansion are bonded together to form the bimetallic strip as shown in fig. It is in the form of a cantilever beam. When the strip is subjected to a temperature higher than the bonding temperature, it will be bent in one direction.

Suppose, it is subjected to a temperature lower than the bonding temperature, it will be bent in the other direction.

The radius of curvature ‘r’ may be calculated as,

![]()

Where,

t = Combined thickness of the bonded strip in mm.

∝1 = Lower coefficient of expansion per °C.

∝2 = Higher coefficient of expansion per °C.

m = Ratio of thickness of low to high expansion materials.

n = Ratio of modulus of elasticity of low to high expansion materials.

T = Temperature in °C.

T0 = Initial bonding temperature in °C.

Material |

Thermal coefficient of expansion per °C |

Modulus of elasticity (GN/m²) |

| Yellow brass | 2.02 x 10-5 | |

| Invar | 1.7 x 10-6 | 147 |

| Stainless steel | 1.6 x 10-5 | 193 |

| Monel 400 | 1.35 x 10-5 | 179 |

| Inconel 702 | 1.25 x 10-5 | 217 |

Applications:

- Bimetallic strips are frequently used in simple ON – OFF switches.

- The bimetal strips are also used in control switches.

Advantages:

- The cost is low when compared to other temperature measuring instruments.

- It has negligible maintenance expense.

- Stable operation over extended periods of time.

- Accuracy of this type of instruments is in between 2 to 5% of the scale.

Disadvantages:

- It is not suitable for more than above 400°C.

- The permanent deformation of metallic strip may occur.

- See More : Laser doppler anemometer

- See More : Current meter is used measure

- See More : Bourdon tube pressure sensor