There are three types of modulus based on different kinds of strain.

They are

- Young’s modulus (Y) (corresponding to longitudinal strain)

- Bulk modulus (K) (corresponding to volume strain)

- Rigidity modulus (N) (corresponding to shear strain)

Young’s modulus (Y)

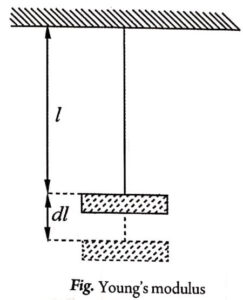

Young’s modulus of the materials of the wire is defined as the ratio of longitudinal stress to longitudinal strain. It is denoted by Y. The unit is N/m²

Consider a wire of length l and area of cross section A to be stretched by a longitudinal force F producing an extension dl (Fig). If Y be the young’s modulus of elasticity, then

∴ Young’s modulus ![]()

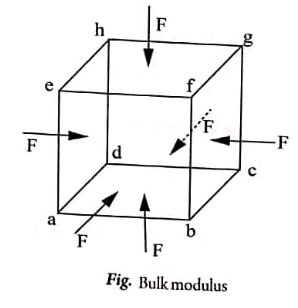

Bulk modulus (K)

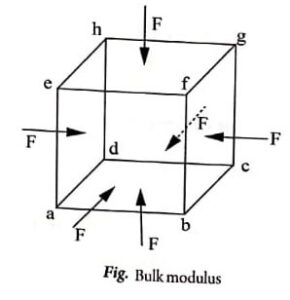

Bulk modulus of the material of the object is defined as the ratio of bulk stress to bulk strain. It is denoted by K. The unit is N/m²

Consider a body of volume V and area of cross section A as shown in (Fig). Let F be the force applied under normal condition to the whole surface of the body. This results in a change in volume but there is no change in shape of the body. Let dV be the change in volume.

![]()

![]()

(The negative sign indicates that volume decreases)

∴ Bulk modulus

![Rendered by QuickLaTeX.com \begin{aligned} \mathrm{K} & =\frac{\text { Bulk stress }}{\text { Bulk strain }} \\ \mathrm{K} & =\frac{\mathrm{F} / \mathrm{A}}{-\frac{\mathrm{dV}}{\mathrm{V}}}=\frac{\mathrm{P}}{-\frac{\mathrm{dV}}{\mathrm{V}}} \quad\left[\because \mathrm{P}=\frac{\mathrm{F}}{\mathrm{A}}\right] \\ \mathrm{K} & =\frac{-\mathrm{PV}}{\mathrm{dV}} \end{aligned}](https://pedagogyzone.com/wp-content/ql-cache/quicklatex.com-5924e0224ada20b929e926af131fbbc3_l3.png)

where P is pressure and equal to force per unit area.

The reciprocal of the bulk modulus is called compressibility.

Rigidity modulus or shear modulus (N)

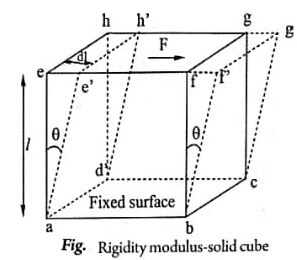

Shear modulus or rigidity modulus of the material of the object is defined as the ratio of shear stress to shear strain. It is denoted by N. The unit is N/m²

Consider a solid cube subjected to a force in the upper portion, as shown in (Fig). The applied force changes the shape of the body without causing any change in its volume.

Positions of the points like e, f, g and h are shifted respectively, to the points e′, f′, g′ and h’. The face efgh is sheared through an angle θ. The vertical faces turn through an angle θ which gives the shearing strain as,

![]()

If the area of top surface is A, then, shearing stress ![]()

∴ Rigidity modulus ![]()

![]()

![]()

| Read More Topics |

| Relation between lattice constant and density |

| Stress – Strain diagram |

| Face centred cubic (FCC) structure |