Abrasives are used in three important forms.

(a) As loose powder:

It is used to clean the surface of materials prior to coating.(e.g.,) Quartz and Garnet.

(b) As abrasive paper or cloth:

The abrasives are used for cleaning and polishing different materials in the form of abrasive paper and abrasive cloth.

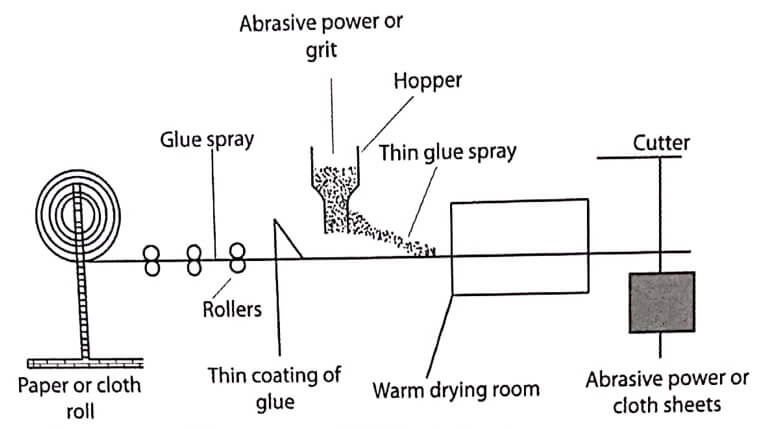

These abrasive paper and cloth are manufactured by passing rolls of paper or cloth through rollers and applying a soft glue on the upper side (Fig 1).

The glue-coated paper or cloth is sprayed with abrasive grains which fall from the top of a hopper. The paper or cloth is again applied with a thin coating of glue followed by drying in a warm room. Finally the dried sheets are cut into various sizes.

Fig (1) Manufacture of abrasive paper (or) cloth

(c) As grinding wheels

Grinding wheels are commonly used in workshop to sharpen tools, edge of knife etc.

Preparation

The synthetic abrasive materials are first crushed in jaw crushers and roller mills. They are then graded according to their grain size.

The abrasive materials of proper grain size are mixed with a binding material and then shaped into moulds by pressing.

Abrasive material + Binding material → Mixture in mould + Pressing → Grinding wheels

The production of grinding wheels depends on the following three factors:

- Selection of abrasives.

- Selection of grain size.

- Selection of binding materials.

| Read More Topics |

| Nickel cadmium NICAD battery |

| Classification and characteristics of a good refractory |

| An overview of primary alkaline battery |