Immobilised enzymes are used in pharmaceutical industries for manufacturing drugs.

These enzymes can be used for:

- Production of antibiotics,

- Production of steroids,

- Production of amino acids,

- Production of acids,

- Production of other organic compounds, and

- Analytical applications.

Production of Antibiotics

Immobilised enzymes are used for producing 6-amino penicillanic acid, penicillins, cephalosporins, etc. on a commercial scale. This process is performed in a column, stirred tank, or a batch membrane reactor.

Penicillins

6-Aminopenicillanic Acid (6-APA): It is manufactured on a large-scale from penicillin G (benzyl penicillin) or penicillin V (phenoxymethyl penicillin) through deacylation with penicillin amidase. To produce semi-synthetic penicillins, 6-APA acts as a significant intermediate. Fermentation process is required for producing these antibiotics. Conventional processes utilising soluble enzymes has been replaced by the processes utilising immobilised enzymes.

Penicillin G: It is manufactured on a large-scale from glucose using conidia, mycelium, and protoplasts of Pencillium chrysogenum immobilised with K-carrageenan, polyacrylamide, and calcium alginate.

A continuous flow bioreactor (of 150ml capacity) is used for this process. Conidia of P. chrysogenum immobilised with K-carrageenan remains useful for 16 days. A yield of 1.2mg/gm, cells/hour from glucose (7.0mg/gm glucose) is obtained.

Ampicillin and Amoxicillin

These two antibiotics can be manufactured with a yield of 50% from 6-APA and D-phenylglycine methyl ester, respectively by continuous flow reaction. In this reaction, cellulose triacetate fibre immobilised with penicillin amidase (obtained from E. coli) is used.

Ampicillin can be obtained with a yield of 67% in a stirred batch reactor by using DEAE-sephadex immobilised with succinolyated penicillin amidase.

Cephalosporins: These can be obtained by fermentation using Cephalosporium acremonium. Various methods are used to immobilise cephalosporin amidase (obtained from various microorganisms). Various cephalosporin derivatives are produced by using the immobilised enzyme systems. Enzymatic deacylation of cephalosporin is done using compounds with 7-ADCA nucleus. The commonly used reaction substrates are 7-phenylacetamidodesacetoxy-cephalosporanic acid (phenylacetyl) and 7-phenoxyacetamidodesacetoxy-cephalosporinic acid (phenoxyacetyl-7-ADCA) obtained through ring expansion reaction involving penicillin and penicillin V.

Celite or alumina immobilised with an enzyme obtained from Bacillus megaterium is useful in the acylation of 7-ACA or 7-ADCA. Cephaloglycine and cephalothin rich in trade are synthesised from 7-ACA and D-phenylglycine methyl ester or 2-thiophene acetic acid by passing the substrate solution continuously through the immobilised enzyme column.

Cephalexin: Cellulose triacetate fibres immobilised with an enzyme obtained from E. coli are used for manufacturing cephalexin from 7-ADCA and D-phenylglycine methyl ester. At 25°C temperature, 75% of the 7-ADCA transforms into cephalexin, in an hour. Immobilised whole cells of Achromobacter sp. dried using acetone and adsorbed on DEAE-cellulose or hydroxylapatite can also be used for producing cephalexin.

C-Bacitracin: Polyacrylamide gel lattice immobilised with enzyme obtained from the cells of Bacillus sp., are useful in batch and continuous culture systems.

D-Tylosin and Nikkomycin: The living cells of Streptomycin ppp. and S. tendae immobilised with calcium alginate are used for producing tylosin (macrolide antibiotic) and nikkomycin (nucleoside peptide antibiotic). Air bubbled reactor is used for continuous production.

Production of Steroids

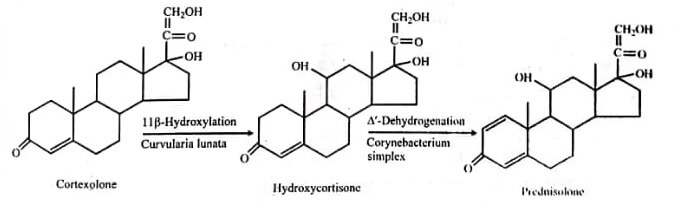

Biocatalytic conversions are used in steroid transformations. Enzymes utilised for steroid transformations need cofactors. Whole cells of microorganisms with cofactors are immobilised to be used for large-scale steroid transformations.

Method 1: Hydrocortisone and prednisolone can be synthesised from cortexolone achieved by immobilising the enzyme by entrapment with polyacrylamide.

Whole cells of Corynebacterium simplex are used for Δ¹-dehydration reaction; and for 11β-hydroxylation reaction, mycelia of Curvularia lunata are used. Prednisolone from cortexolone can be produced by combining these immobilised systems.

Method 2: To obtain prednisolone from hydroxycortisone, whole cells of C. simplex entrapped in collagen membrane are employed. For continuous operation, chips of collagen cell complex packed in column are used.

Method 3: By combining C. lunata mycelia and immobilised Arthrobactor simplex cells the two step transformation (i.e., cortexolone to its Δ¹-dehydro-11-hydroxy derivative) can be carried out.

Production of Amino Acids

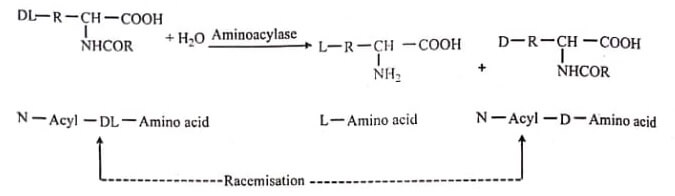

Pharmaceutical industries employ amino acids for various purposes. There are several existing large-scale processes employing immobilised enzymes. Production of amino acids by enzymatic resolution involving amino acid acylase and fructose syrups obtained from glucose isomerase is an example.

Optical Resolution of DL-Amino Acids: L-amino acid and unhydrolysed acyl-D-amino acid is produced by the asymmetric hydrolysis of acyl-DLamino acid using aminoacylase. Both the products are separated through solubilisation. Unhydrolysed acyl-D-amino acid is further racemised to be reused in the resolution procedure.

Immobilised aminoacylase obtained from Aspergillus oryzae is employed in continuous optical resolution of DL-amino acids. Aminoacylase can be immobilised by ionic binding to DEAE-sephadex (commonly used in industrial process), covalent binding to lidoacytyl cellulose, and entrapment in polyacrylamide gel. Acetyl-DL-amino acid solution is continuously fed in the enzyme column through a filter and heat exchanger. The enzyme reaction takes place while moving through the column.

During the reaction, concentrated effluent crystallises out the L-amino acid. The acyl-d-amino acid present in the mother liquor is racemised by heating and reused for optical resolution.

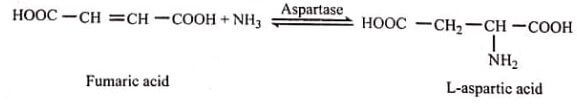

Optically Active Amino Acids – L-Aspartic Acid: L-aspartic acid is industrially synthesised by fermentation or enzymatic batch process using fumaric acid and ammonia along with aspartase.

Whole cells of E. coli immobilised with K-carrageenan are treated with glutaraldehyde and hexamethylenediamine. These immobilised cells with highest productivity are packed into column and have a half-life period of 680 days at 37°C temperature.

Production of Acids

Immobilised enzymes yield better productivity of organic acids. There are many processes available for the production of acetic acid by Acetobacter aceti immobilised with porous ceramics, of citric acid by A. niger immobilised with calcium alginate, of lactic acid by L. casei immobilised with polyacrylamide, of L-malic acid by. Bravibacterium flavum immobilised with carrageenan, of 12 ketochenodeoxycholic acid by. B. fuscum immobilised with carrageenan, of 2 ketogluconic acid by Serratia marcescens immobilised with collagen, etc.

Other Organic Compounds

Other organic compounds that can be produced by immobilised enzymes are:

Coenzyme A: It can be produced continuously from pantothenic acid, Lcysteine, and ATP using Bravibacterium ammoniagenes cells immobilised on polyacrylamide gel.

Flavin Adenine Dinucleotide (FAD): It can be produced from flavin-mononucleotides and ATP using whole cells of Arthrobacter oxydans immobilised on a film of polyvinyl alcohol cross-linked with tetraethylsilicate. The FAD pyrophosphorylase activity is high in these cells.

Pyridoxol 5′-Phosphate: It can be produced from pyridoxine 5′-phosphate using whole cells of Pseudomonas fluorescens immobilised on a film of polyvinyl alcohol cross-linked with tetraethylsilicate. Pyridoxol 5′-phosphate has a high enzyme activity.

Adenine Arabinoside: The cells of Enterobacter aerogenes bear transglyosylation activity. These cells are immobilised with hydrophilic photocrosslinkable resin, and used to produce adenine arabinoside from uracil arabinoside and adenine in a proper water-organic solvent system.

Vitamin B12 : It can be produced using cells of immobilised Propionibacterium sp.

Dihydroxy Acetone: It is a pharmaceutical intermediate, and can be produced through glycerol oxidation with cells of Acetobacter xylinum immobilised on polyacrylamide gel.

Proinsulin: The plasmids of Bacillus subtilis cells having gene encoding for proinsulin can be immobilised on agarose beads. These immobilised cells can then be used for proinsulin production in a small continuous stirred tank reactor.

Interleukin-2 and Monoclonal Antibodies: These can be produced using animal cells (lymphoblastoid MLA 144 cells and hybridoma cells) immobilised on agarose beads.

Prostaglandin: It can be produced from arachidonic acids by using ram seminal microsomes immobilised on photocrosslinkable resin.

Ajmalicine Isomers: These can be produced from tryptamine using cells of the plant, Catharanthus roseus immobilised with calcium alginate.

Anthraquinones: These can be produced by De novo synthesis from secologanin using cells of the plant, Morinda citrifolia immobilised with calcium alginate.

Analytical Applications

Given below are the analytical applications of immobilised enzymes:

Enzyme Electrodes: These are probes which can generate an electrical potential when a reaction catalysed by an immobilised enzyme (fixed on or around the probe) occurs. In automated analysis, immobilised enzymes are used for replacing the soluble enzyme in an existing automatic analyser system.

Affinity Chromatography and Purification: Immobilised enzymes are also used in affinity chromatography. The species having a high affinity for the material to be removed from solution allows the purification or analysis of enzyme inhibitors, cofactors, antigens, antibodies, and other substances.

Biosensors: These are devices, probes, or electrodes having immobilised enzyme which on contact with a sample converts the presence of the desired analyte into physical, chemical or electrical signals which are measured. The sample concentration is measured in the form of electrical signals, or with a biological recognition system combined with an electrochemical transducer. Biosensors respond reversibly and specifically to the variation in the concentration of biochemical event of great practical utility.

| Read More Topics |

| Applications of biotechnology in pharmaceutical sciences |

| General procedure of cell culture |

| Growth of animal cells in culture |

| Evaluation of microbial stability of formulations |