For calibration of temperature measuring devices, a constant temperature source should be provided. The temperature source should as a minimum be stable enough to provide a constant temperature. (approximately ±0.2°F) for a short length of time at any temperature. The temperature source should have a zone of uniform temperature into which the temperature measuring devices may be inserted. The length of the temperature source must be adequate to permit a depth of immersion sufficient to assure that the measuring junction temperature is not affected by a temperature gradient along the thermocouple wires.

These are two methods used to calibrate the temperature measuring devices.

(i) Cold temperature or ice bath check

(ii) Hot temperature check

Cold Temperature or Ice Bath Check

One of the most common methods of calibrating the temperature measuring devices is the ice bath or cold temperature check. Here, the methods of calibrating thermocouple and thermometer are given under.

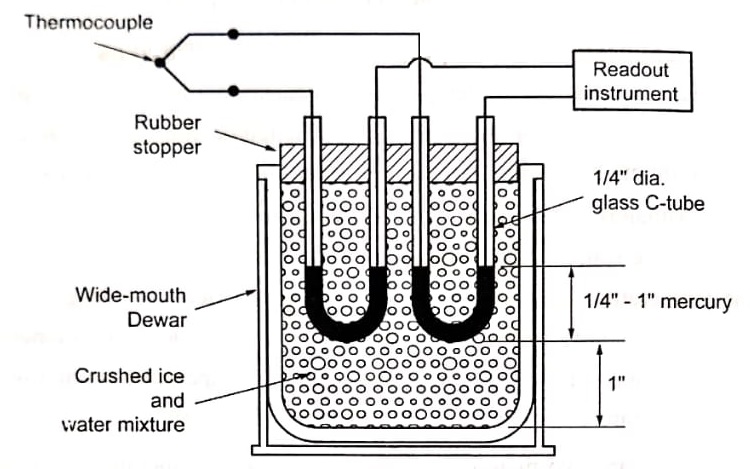

The ice bath is made up of a mixture of melting shaved or crushed ice and water. The ice bath is a convenient and inexpensive way to achieve an ice point (i.e., reference junction or temperature source), it can be reproduced with ease and with exceptional accuracy. Junctions formed between the thermocouple materials and instrument leads can be simply immersed into such mixture, or alternatively glass ‘U’ tubes containing a quantity of mercury approximately ¾” to 1 ” depth can be placed into the slush mixture. Quick electrical connection can then be made between thermocouple and instrument leads through the mercury as shown in fig.

The same set up can be used to calibrate thermometer with slight modification. Place the thermometer at the centre of the container to a depth of at least 50mm and should be frequently agitated with agitator. The temperature should be noted after the reading has stabilized (after about 3 minutes) and must be between 30° to 34°F or -0.5°C to +0.5°C,

Hot Temperature Check

In this method of calibration of thermocouple, both reference thermocouple and thermocouple to be calibrated are inserted in a hot temperature source. The temperature source is a electrical furnace in which the copper blocks are kept to inert both thermocouples. The copper block is shielded by radiation resistant material to avoid radiations of the furnace walls. The electrical furnace is switched on and kept for some time for attaining constant temperature. Now, the temperature of both the thermocouple are noted and compared for calibration. The difference in temperature must be ±0.5°C.

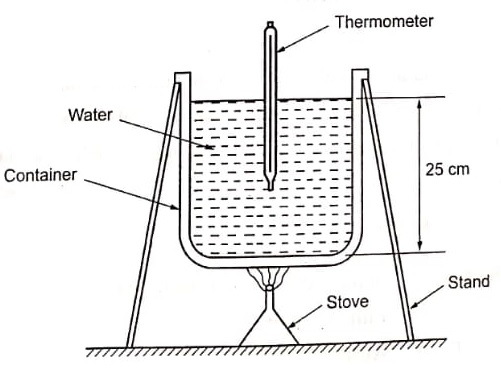

For calibrating thermometer, a 25cm deep container of water should be brought to a rolling boil on a stove or other sources of constant heat. The thermometer to be calibrated is immersed in the water. The temperature should be noted after the reading has stabilized (after about 3 min.) and must be between 210°F to 214°F or 99.5°C to 100.5°C.

| Read More Topics |

| Control system in mechatronics |

| CNC – CMM Features |

| Types of measuring machine |

| Measuring instruments |