Capacitive Displacement Sensors

A transducer that uses capacitance variation can be used to measure displacement. Elastic deflection of a membrane due to the applied force is detected by a capacitance variation. A highly sensitive displacement and proximity transducers can be constructed because the Capacitive displacement sensors transducer senses very small deflections accurately. Capacitive sensors can directly sense a variety of things such as motion, chemical composition, electric field and indirectly sense a variety of things such as motion, chemical composition, electric field and indirectly sense many other variables which can be converted into motion or dielectric constant, such as pressure, acceleration, fluid level, and fluid composition.

A capacitance sensor consists of two metal plates separated by an air gap. The capacitance C between terminals is given by the expression.

Where C = Capacitance in Farads (F),

Εr = Relative dielectric constant of the insulator,

E0 = Dielectric constant of free space,

A = Overlapping area for the two plates,

H = Thickness of the gap between two plates

Different forms of capacitive displacement sensors are shown in image 36, where one plate of the capacitor inside a probe which is sealed in an insulator and the external target object forms the other plate of the capacitor. The operating principle is based on either the geometry (i.e. ., the distance d), or capacitance variations in the presence of conductive or dielectric materials. Distance variation of parallel plates (a) is often used for proximity or motion detection if the distance change is less than the plate size. Transverse displacement is easily detected by overlap or underlap area of the parallel plates. (b) In the distance variation motion detectors, when displacement increases to the dimension of the plates, measurement accuracy suffers from vanishing signal level. Area variation is then preferred. As these plates slide transversely, capacitance changes linearly with motion. Quite long excursions are possible with good linearity, but the gap needs to be small and well-controlled, Used as proximity sensors, capacitive sensors can detect metallic or nonmetallic objects, liquids, or any object with a dielectric constant greater than air. The dielectric object is kept between the plates as (c). As the dielectric object moves between the plates, the capacitance changes linearly with motion.

While using two plates capacitive sensor, there is a non-linear relationship between displacement and the change in capacitance exist. Thus can be overcome by using three plates capacitive sensor, called push-pull displacement sensor. In this type, the upper pair of plates forms one capacitor as shown in image. When the central plate moves upward, the separation of upper pair decreases and the separation of lower pair increases. Therefore, the capacitance of a parallel plate capacitor is given by

Where Er = Relative permittivity of the dielectric between the plates

E0 = Permittivity of free space constant,

X = Displacement of central plate,

A = The area of overlap between the two plates,

D = Distance of the plate separation.

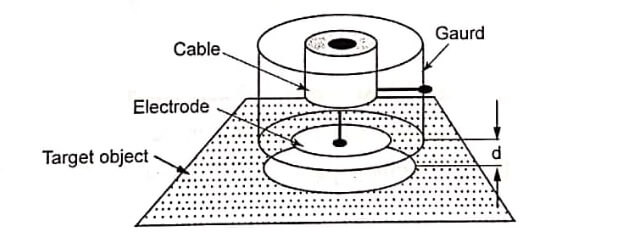

One form of capacitive proximity sensor is shown in image, where one plate of a capacitor is connected to the central conductor of a coaxial cable, while the other plate is formed by a target object. The operating principle is based on either the geometry (i.e., the distance d), or capacitance variations in the presence of conductive or dielectric materials.

Applications

This sensor can be employed for measuring position, displacement, gauging, or any other similar parameter in a machine tool.

Advantages

- Excellent linearity over entire dynamic range when area is changed (sine stray electric fields are small)

- High sensitivity.

- Capacitive displacement detectors can detect 10-14 m displacements with good stability, high speed, and wide extremes of environment.

- The system responds to average displacements of a large area of a moving electrode.

- Freedom of electrode (plate) materials and geometry for demanding environments and applications.

- Fractional change in capacitance can be made large.

- Capacitive sensors can be made to respond to displacements in one direction only.

- The forces exerted by the measuring apparatus are electrostatic and usually small enough so that they can be disregarded.

- Capacitors are noiseless.

- High accuracy and resolution. A resolution of 2.5 x 10-3 can be obtained.

Disadvantages

- The performance of these sensors is likely affected due to the environmental conditions such as dust, moisture, vibration etc.

- The metallic parts of the capacitor must be insulated from each other.