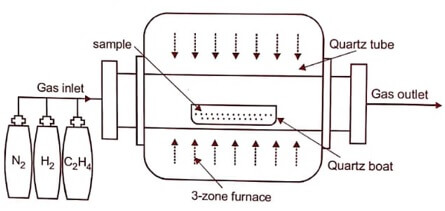

- It is a method in which the reaction or thermal decomposition of gas phase species at higher temperature (500 – 1000°C) and then nanoparticles deposition on a substrate takes place.

- In chemical vapour deposition method carbon nanotubes are also grown from the decomposition of hydrocarbons at temperature range of 500 to 1200°C.

- In this process, the substrate is placed inside a reactor to which a number of gases are supplied. The fundamental principle of the process is that a chemical reaction takes place between the source gases. The product of that reaction is a solid material with condenses on all surfaces inside the reactor.

Example of CVD technique

Fig 1.1

- Aerosol spray pyrolysis (Pyrolysis is the chemical decomposition of organic materials by heating in the absence of oxygen or any other reagents is th example of CVD technique.

- In which high aqueous metal salts are sprayed in the form of fine mist and then passed into a hot flow tube.

- In the hot flow tube pyrolysis converts the salts into the final products on the substrate.

- In this method the materials are mixed in a solution, homogeneous mixing is obtained at the atomic level.

- The pyrolysis at low temperature gives the particles in the size range 5 – 500 nm .

- In this CVD method catalysts are used for better chemical reactions.

- When the catalyst is in nanosize, dispersion of particles is happened due to templating effect.

- In the Production of carbon nanotubes using the decomposition of ethene with hydrogen, Fe, Co or Ni based catalysts are used.

- the size and distribution of the catalyst particles determine the internal diameter of the nanotube.

| Read More Topics |

| Semiconducting material – Questions and Answers |

| Electrical conductivity in intrinsic semiconductor |

| Mobility and conductivity in semiconductors |