In petrol engines, a carburetor is employed to mix air and fuel supply system in the desired ratio. But in diesel engines, air alone is compressed in the cylinder. The high pressure is about 35 to 40bar and the temperature of this air after compression is about 600°C. At the end of compression stroke, the fuel is injected through fuel nozzle in fine atomized form at a pressure higher than that of air.

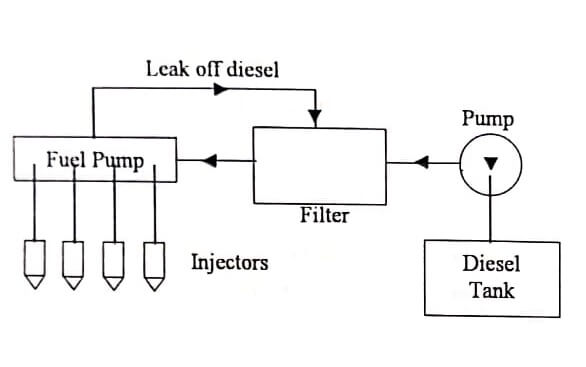

Fig. shows a fuel injection system for diesel engine. It consists of a fuel tank, fuel feed pump, fuel filter, fuel injection pump and injector.

Fuel is pumped to the fuel injection pump from fuel tank through fuel filter. From the fuel injection pump, the fuel is delivered to the fuel nozzle or injectors.

These injectors spray the fuel into the cylinder in the form of fine atomized spray.

Requirements of fuel injection system :

- The beginning as well as end of injection should take place sharply.

- Inject the fuel at correct time in the cycle throughout the speed range of the engine.

- The injection of fuel should occur at the correct rate and in correct quantity as required by the varying engine load.

- Atomize the fuel to the required degree.

- Distribute the fuel throughout the combustion chamber for better mixing.

METHODS OF FUEL INJECTION

There are two methods of fuel injection used in C.I engines:

a) Air injection system.

b) Air-less or solid injection.

Air injection system

In this method, initially air is compressed to a very high pressure by means of compressor. The fuel was metered and pumped to the nozzle, which was also connected to a source of high pressure air.

When the nozzle was opened, the air would sweep the fuel into the engine and deliver a well atomized spray. This method is not used now-a-days because of complicated and expensive system.

Airless or Solid injection

This method has greatly replaced the air injection method. The fuel under pressure is directly injected into the combustion chamber in atomized state.

It requires a pump to deliver the fuel at high pressure (as high as 300bar abs). It may be further classified into the following two commonly used systems.

a) Common rail system.

b) Individual pump system.

Common rail system

Fig. shows this system in which a multi cylinder high pressure pump is used to supply the fuel at a high pressure to a common rail or header. A metered quantity of fuel is supplied to each cylinder from the rail.

Individual pump system

In this system, each cylinder of the engine is provided with an individual injection valve, a high-pressure pump and a metering device.

It is quite compact but since at all operating loads and speeds each pump in this unit should very precisely match its companions, extremely close tolerances are required during manufacturing. Therefore, it involves higher costs.

| Read More Topics |

| Centrifugal governors |

| Diesel power plant |

| Governor vs flywheel |