Types of glasses

The following types of glass are discussed in brief.

1.Soda lime or soft glass or commercial glass

Raw materials:

It is a mixture of silica (sand), calcium carbonate and soda ash. Composition Na2O CaO 6SiO2 .

Properties:

(i) It is cheap.

(ii) It is easily fusible at low temperature.

(iii) It melts easily.

(iv) It is attacked by common reagents like acids.

Uses : It is widely used as window glass, electric bulbs, bottles, jars etc.

2.Potash lime or hard glass

Raw materials

It is a mixture of silica (sand), calcium carbonate and potassium carbonate. Composition K2O CaO 6SiO2 .

Properties

(i) It fuses at high temperature.

(ii) It is not easily affected by water and other solvents.

(iii) It does not melt so easily.

Uses: It is used for manufacturing chemical apparatus, combustion tubes etc., which are in turn used for heating operations.

3. Potash lead glass or flint glass

Raw materials:

It is a mixture of lead oxide, potassium oxide and silica. Composition K2O PbO 6SiO2 .

Properties:

(i) It fuses very easily.

(ii) It is easily attacked by aqueous solutions.

(iii) It is more expensive than ordinary lime soda glass.

(iv) It has higher refractive index and excellent electrical properties.

(v) It is bright and lustrous.

Uses: Lead glass is are used widely for optical purposes (like lenses etc.), cathode-ray tube and electrical insulators.

4. Borosilicate glass or pyrex glass or jena glass

Raw materials:

It is a mixture of silica and boron, with a small amount of alumina and some alkali oxides, Composition: SiO2(80.5%) B2O3(13%) Al2O3(3%) K2O(3%) Na2O(O.5%).

Properties:

(i) It has very high softening points and shock-proof property.

(ii) It is highly heat resistant.

(iii) It does not crack on heating.

Uses: This glass is widely used in the chemical industry, for laboratory apparatus.

It is used to make protective helmets, boats, piping and car exhausts.

5. Common glass or bottle glass

Raw materials:

It is mainly a mixture of sodium silicate, calcium silicate and iron silicate.

Properties:

(i) It fuses with difficulties.

(ii) It is brown, green or yellow in colour.

(iii) It is easily attacked by acids.

Uses: It is mainly used in the manufacture of medicine bottles.

6. Silica glass or Vitreosil

Raw materials:

It is produced by heating pure SiO2 to its melting point (or about 1750°C).

Properties:

- Its softening temperature is about 1650°C .

- It possesses lower thermal expansion.

- If Vitreosil glass is heated for long period, above its melting point, it finally becomes transparent and is then known as ‘Clear silica glass’, i.e., glass of considerable light transmission properties.

Uses: It is used mainly for chemical plants, chemical laboratory wares, electrical insulating materials in electrical heaters, furnaces etc.

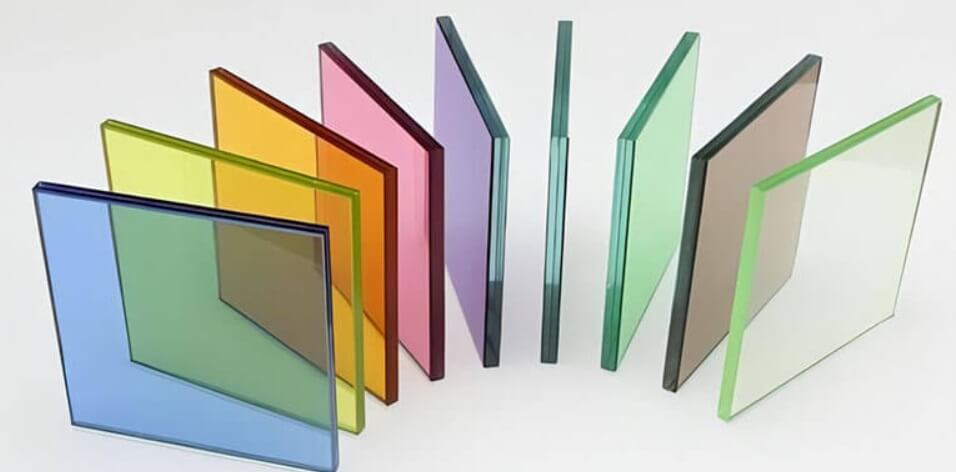

7. Safety glass

Raw materials:

It is made by placing a sheet of a plastic such as celluloid between sheets of glass under pressure. It is then heated till the glass layers and plastic layers from a sandwich.

Properties:

(i) It is very tough.

(ii) It does not break easily.

(iii) It is not easily attacked by acids.

Uses: It is mostly used in automobile and aero plane industries as wind shields etc.

8. Optical or Crookes glass

Raw materials

Phosphorus and lead silicate together with a little cerium oxide to absorb ultraviolet light are used in the preparation…

Properties:

(i) It has low melting point.

(ii) It is relatively soft.

(iii) It possesses low chemical resistance.

Uses: It is used for making lenses.

9. Laminated glass or bullet-proof glass

(i) The laminated glass is shatter proof.

(ii) It is shock proof.

(iii) It is stronger than safety glass.

Uses: It is used as safety glass in aircrafts, automobile, helicopters etc.

10. Glass wool

(i) It has low electrical conductivity.

(ii) It possesses high tensile strength.

(iii) It is fire and heat proof.

(iv) It does not absorb moisture.

Uses: Glass wool is mainly used as heat insulating material.

It is used as air filter or dust filter where it acts as a filtering medium to most of the corrosive liquids.

| Read More Topics |

| Important aspects of cement |

| Manufacture of common refractories |

| Classification and characteristics of a good refractory |