A tire pressure sensor is a small programmable electronic device, located in the pressurized pocket made by a wheel and tire, that constantly measures the air pressure inside the tire. The tire pressure sensor transmits that information via low-frequency radio to the vehicle’s onboard computer and, if the car has one, to a corresponding display in the instrument cluster. It reads out in pounds per square inch (psi), and it illuminates an amber warning light to alert you if one or more tires are low on air.

If you own a car built after 2007, you have a tire pressure monitor system at work. You know it best as the horseshoe shaped light (it’s actually a stylized, flattened tread and sidewall of a tire) with an exclamation point in the center. It’s also the light that can plague you by coming on and going off at inexplicable times, and sometimes signaling an expensive trip to the dealership.

Tire pressure sensors are integral to what is known as the Tire Pressure Monitoring System (TPMS). Millions of these systems have been fitted to passenger vehicles since the 2008 model year, when they were made mandatory in the United States. Tire pressure sensors are usually attached to the valve-stem assembly of each tire and are powered by batteries.

But this indicator light is the visible part of a larger pressure monitoring system, and it’s there to help. When it’s on, it’s telling you that your tires need air.

Direct TPMS : uses a sensor mounted in the wheel to measure air pressure in each tire. When air pressure drops 25% below the manufacturer’s recommended level, the sensor transmits that information to your car’s computer system and triggers your dashboard indicator light.

Indirect TPMS : works with your car’s Antilock Braking System’s (ABS) wheel speed sensors. If a tire’s pressure is low, it will roll at a different wheel speed than the other tires. This information is detected by your car’s computer system, which triggers the dashboard indicator light.

Bellows pressure sensor

- The bellows is a one-piece, collapsible, seamless metallic unit that has deep folds formed from very thin-walled tubing. It looks like a stake of capsules. It is more sensitive than the diaphragm and capsule pressure sensors. The diameter of the

bellows ranges from 1.2 to 30 cm and may have as many as 24 folds. System pressure is applied to the internal volume of the bellows. As the inlet pressure varies, the bellows will expand or contract. The moving end of the bellows is connected to a mechanical linkage assembly. - The deflection can be measured in any number of ways. For example, it can be detected via a mechanically-coupled indicating needle [refer Figure (a)], a linear variable differential transformer (LVDT) as described in the diaphragm pressure gauge [refer Figure (b)], a potentiometer [refer Figure (b)]. or with many other displacement sensors. As the bellows and linkage assembly moves, either an electrical signal is generated or a direct pressure indication is provided. Figure shows a bellows pressure sensing element along with the potentiometer.

- The potentiometric bellows pressure sensor provides a simple method for obtaining an electronic output from a mechanical pressure gauge. The device consists of a precision potentiometer, whose wiper arm is mechanically linked to a bellows or Bourdon element. The movement of the wiper arm across the potentiometer converts the mechanically detected sensor deflection into a resistance measurement, using a Wheatstone bridge circuit.

- The flexibility of a metallic bellows is similar in character to that of a helical. coiled compression spring. Up to the clastic limit of the bellows, the relation between increments of load and deflection is linear. In practice, the bellows must always be opposed by spring, and the deflection characteristics will be the resulting force of the spring and bellows.

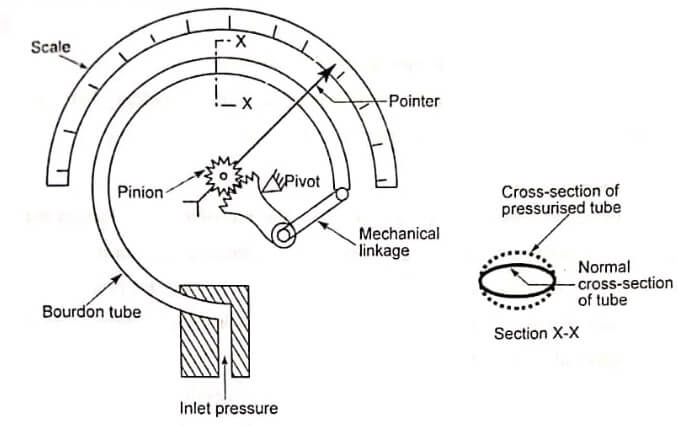

Bourdon tube pressure sensors

The bourdon tube pressure instrument is one of the oldest pressure sensing instruments in use today. It is widely used in applications where inexpensive static pressure measurements are needed. The bourdon tube consists of a thin-walled C.

shaped tube that is flattened diametrically on opposite sides to produce a cross- sectional area elliptical in shape, having two long flat sides and two short round sides. The tube is bent lengthwise into an arc of a circle of 270, to 300 degrees.

Bourdon tube is open to external pressure input on one end and is coupled mechanically to an indicating needle on the other end, as shown schematically in Figure. Pressure applied to the inside of the tube causes distention of the flat sections and tends to restore its original round cross-section. This change in cross-section causes the tube to straighten slightly.

Since the tube is permanently fastened at one end, the tip of the tube traces a curve that is the result of the change in angular position with respect to the center. Within limits, the movement of the tip of the tube can then be used to position a pointer or to develop an equivalent electrical signal to indicate the value of the applied internal pressure.

The deflection of the Bourdon tube can be measured in any number of ways. For example. it can be detected via a mechanically coupled indicating needle [refer Figure]. a linear variable differential transformer (LVDT) as described in the diaphragm pressure gauge [refer Figure (b)], or (b)], a potentiometer [refer Figure 1.66 with many other displacement sensors.

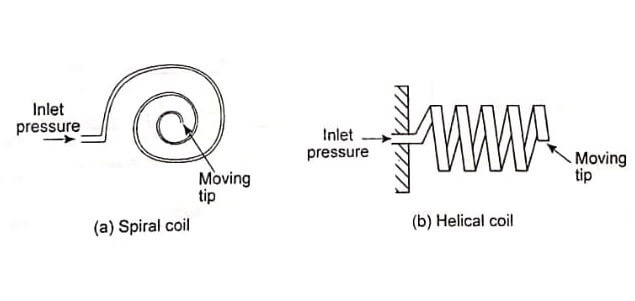

To increase their sensitivity, Bourdon tube elements can be extended into spirals or helical coils [Figures (a) and (b)]. This increases their effective angular length and therefore increases the movement at their tip, which in turn increases the

resolution of the transducer.

Advantage :

- Portable

- Convenient to use

- No leveling required

Disadvantages :

- Limited to static or quasi static measurements.

- Accuracy may be insufficient for many applications. A mercury barometer can be used to calibrate and check bourdon tubes.

| Read More Topics |

| Piezoelectric pressure sensor working principle |

| How does a tactile pressure sensor work |

| Bourdon tube pressure sensor working |