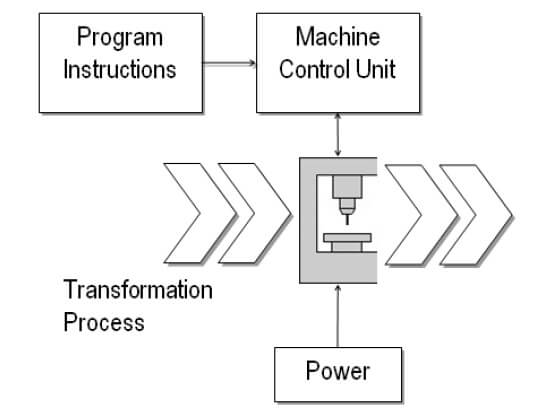

NC machine tool by means of prepared program, which consists of blocks, or series of numbers, is know as numerical control (NC). In manufacturing of more complicated parts, the system has to calculate automatically additional data points, which is done by means of an interpolator

- The capability of changing the programs provides the advantage of machining wide variety of workpiece in a single machine.

- Fixture designed for one shape and size of the workpiece may not suite for another.

- Since an NC machine handles more variety of workpiece, it is impossible to design fixtures for each workpiece.

- One fixture for one component leads to increase the cost of manufacturing and maintaining the fixtures. It also occupies more storage space and is obsolete, if the workpiece is changed or eliminated.

Need of Fixtures for NC Machine Tool

- Fixture can be universal

- Fixture should be designed to hold more than one size of workpiece

- Fixture should be able to rearrange to fit a variety of workpiece.

Fixtures for Numerical Machine Tools

To satisfy the needs NC machine fixtures, general purpose work holding devices are commonly used. The work holding devises used in NC machine tools are,

- Strap Clamp or heel block

- Standard vises and chucks

- Modular fixtures.

What is NC Machine Tool?

programmable automation in which the processing equipment (machine tool) is controlled by coded instructions using numbers, letter and symbols Numbers form a set of instructions (or NC program) designed for a particular part.

Although the most popular applications of NC are in machining, NC can be applied to many other operations, including welding, sheet metalworking, riveting.

Features of Numerical Machine Tool

NC machine tools are capable of machining at very close tolerances, in some operations as small as 0.005 mm. NC systems are capable of maintaining constant working conditions for all parts in a batch thus ensuring less spread of quality characteristics.

NC machines, advantages of NC machines, Types of NC systems, Controlled axes, Basic Components of NC Machines, Problems with Conventional NC and Principles of NC Machines are described in this Unit.

According to these definitions, a programme is prepared which consists of blocks, blocks consisting of combination of characters and numbers in sequence describing the position of the tool and job, the cutting speed and feed.

The data converted into coded instructions which are called a Part Programme. As the job changes, the instructions of part program are also changed. The other instructions which can be included may be for tool changing or coolant on and off.

It is easy to encode a new programme than to change the machinery for flexibility, thus arising the need of an NC machine tool.