Most of the conventional pressure gauges are of a mechanical type. These gauges embody on elastic element which deflects under the action of the applied pressure. This movement mechanically magnified and read with the help of pointer and graduated scale. These pressure gauges are generally used for measuring high pressures and where the high precision is not required. The various mechanical gauges which are commonly used are:

- Bourdon tube pressure gauge

- Bellows pressure gauge

- Diaphragm pressure gauge

- Dead-weight pressure gauge

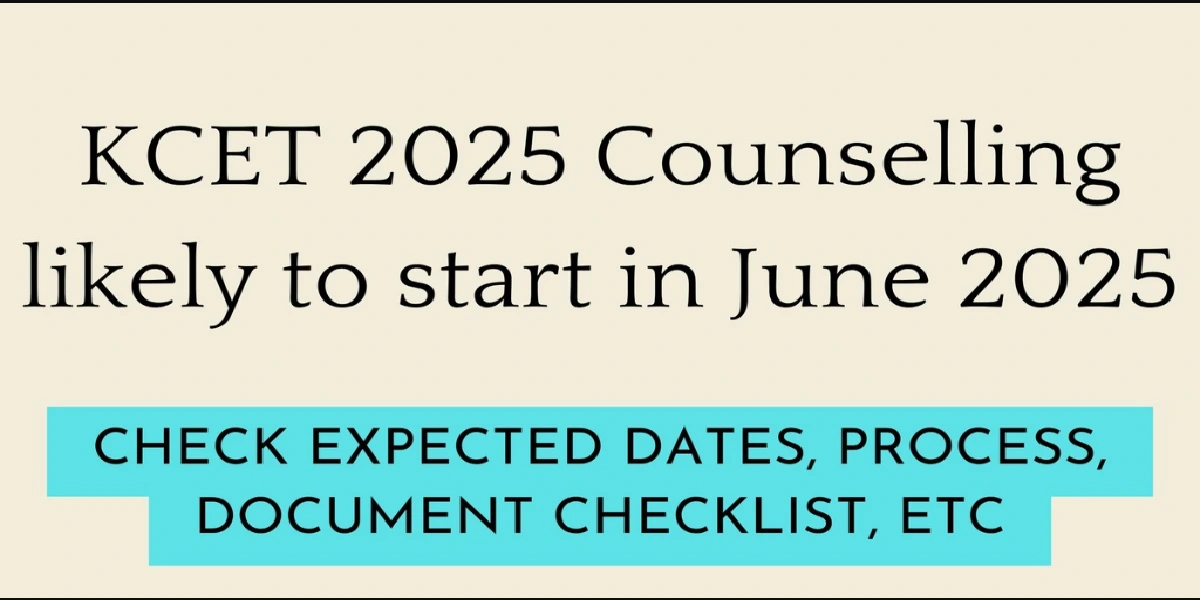

Bourdon Tube Pressure Gauge

The bourdon tube pressure instrument is one of the oldest pressure gauge instruments in use today. It is widely used in applications where inexpensive static pressure measurements are needed. Bourdon tube is a simple tube which will expand when it is exposed to pressure. This expansion is then the measure of pressure. A bourdon tube is shown in figure.

One end called tip of the tube is sealed and is called free end. This is attached by a light link-work to a pawl and ratchet mechanism which operates the pointer. The other end of the tube is fixed to a socket where the pressure to be measured is applied. The internal pressure tends to change the section of the tube from oval to circular and it tends to straighten out the tube. The movement of the tip is ideally proportional to the pressure applied. The tip is connected to a spring loaded link-work and a geared sector and pinion arrangement which amplifies the displacement of tip and converts into the deflection of the pointer.

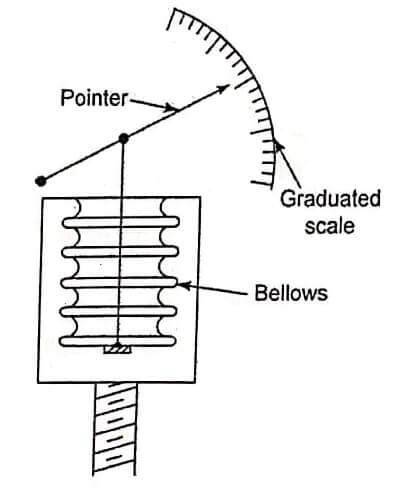

Bellows Pressure Gauge

In this gauge, bellows are used as a pressure responsive element. It is made up of a thin metallic tube having deep circumferential corrugations. When the magnitude of pressure changes this elastic element expands or contracts thereby moving the pointer on a graduated circular dial as shown in figure.

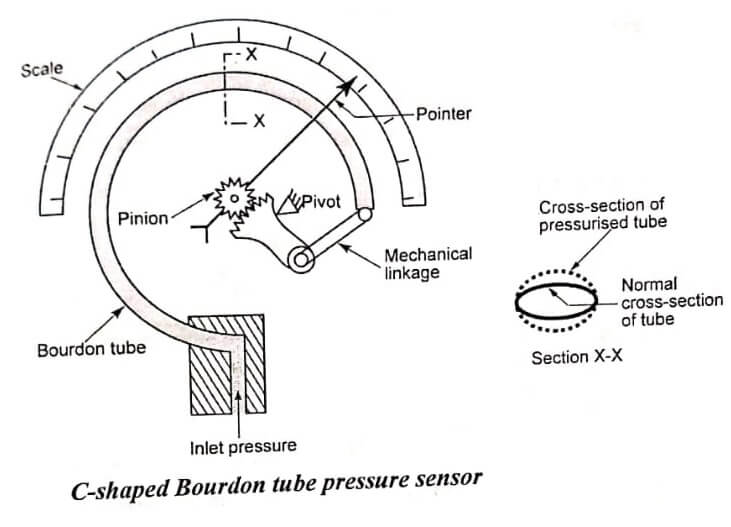

Diaphragm Pressure Gauge

In a diaphragm pressure gauge, an elastic diaphragm is used as a pressure responding element. Diaphragm is a thin circular elastic membrane made of generally silicon. Diaphragms are made either flat or corrugated shape as shown in figure (a) and figure (b).

As the pressure changes, the diaphragm will move and this motion is the measure of differential pressure. The pressure above or below the atmospheric pressure is also found out with the help of this gauge. This gauge is relatively used to measure low pressure intensities. The elastic deformation of the diaphragm under pressure is transmitted to a pointer by a similar arrangement as in the case of bourdon tube pressure gauge as shown in figure.

The materials for the diaphragms are chosen in such a way that

- their physical properties are compatible with the load.

- their flexibility provides the required sensitivity of the elastic transducer.

- the natural frequency of the diaphragm is high enough to provide a good frequency response, and

- the output is linear.

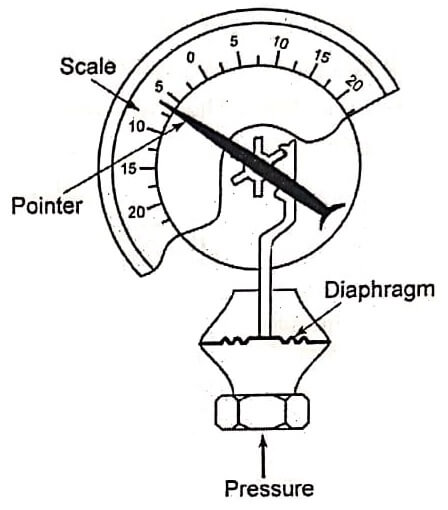

Dead Weight Pressure Gauge

- See More : Pressure measurement by manometer

- See More : Filled system temperature measurement

- See More : Device used for measurement roundness

- See More : Straightness measurement