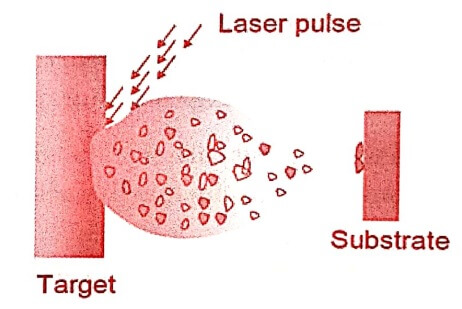

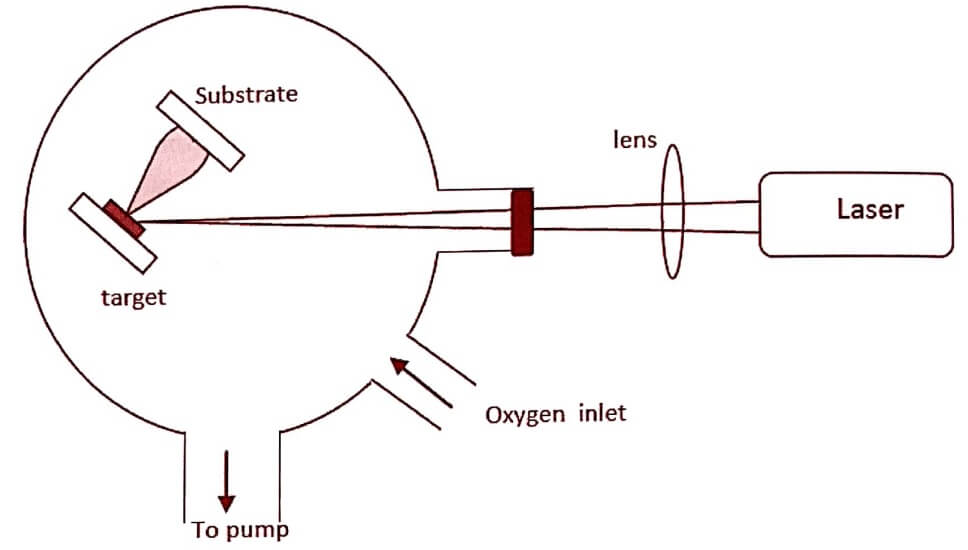

Laser ablation or deposition was utilized for the first time in the 1960’s, after the first laser (ruby laser) was invented. Then the pulsed laser deposition (PLD) technique has been more rapid and the amount of research devoted to this topic has increased largely. The growth and quality of the resulting film will generally depend on a number of fundamental parameters, including the choice of substrate, the substrate temperature and the absolute and relative kinetic energies and/or arrival rates of the various constituents within the plume.

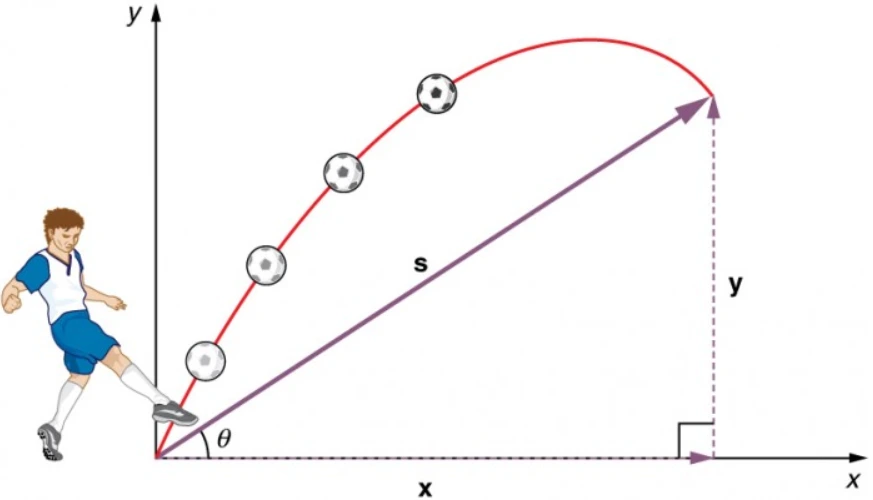

Fig 1.1

The pulsed laser deposition (PLD) technique is a powerful method for the deposition of multi-component materials, since it transfer the stoichiometry from a given ceramic or single crystalline target to the deposited thin film.

Fig 1.2

A laser beam is transferred through a optical system to the rotating target. The laser pulse with a high energy evaporate of the target surface and the form the plasma immediately, containing energetic neutral atoms, ions and molecules. This so-called “plume” reaches the substrate surface with an energy of 0.1 to >10eV, depending on the pressure of the background gas environment.

As a result of the short, high energetic laser pulses, the evaporated material is not in the thermodynamic equilibrium and the relative amount of different compounds in the plume corresponds to the target composition even for strongly-differing melting points.

Therefore, in contrast to most other deposition techniques, the desired thin film stoichiometry can by easily achieved by PLD.

| Read More Topics |

| Synthesis of nanomaterials |

| Advanced engineering materials – Questions and Answers |

| Magnetic recording materials |