A robot moves in space to perform tasks and hence it needs actuators to move the links and sensors to know where each joint is. Sensors inform the controller by how much each joint has moved and thus enables the controller to enforce a particular velocity or position during motion.

As we have seen in the previous section each joint has an independent control structure in which there is an actuator, reduction gear mechanism and a sensor at each joint.

Sensors can be divided into two parts:

Internal sensors – These are responsible for the internal working of the robot and are mainly used for closing the loop in feedback control e.g., position sensors. A robot cannot function properly without these if it is using a closed loop feedback control system. The main internal sensors are position and velocity sensors.

External sensors – These are responsible for interaction with the environment. A robot can use external sensors like touch sensor for interaction with the environment.

In case any of these sensors fail the robot can still function but its ability to interact with the external world is reduced.

External sensors are of many different types depending on the kind of interaction with the environment. The main external sensors are force/torque sensors, vision, touch, pressure sensors, etc.

Position and velocity sensors

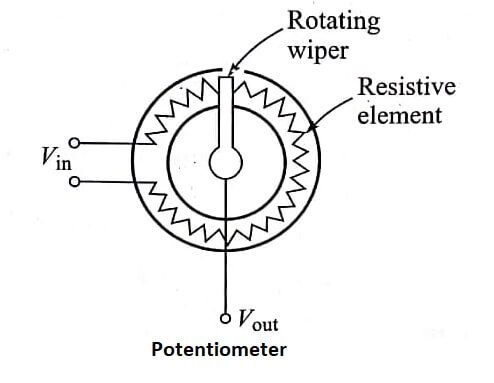

Potentiometers Potentiometers are analog devices whose output voltage is proportional to the position of a wiper. Fig illustrates a typical pot.

A voltage is applied across the resistive element. The voltage between the wiper and ground is proportional to the ratio of the resistance on one side of the wiper to the total resistance of the resistive element.

Essentially the pot acts as a voltage divider network. That is, the voltage across the resistive element is divided into two parts by a wiper.

Measuring this voltage gives the position of the wiper. The function of the potentiometer can be represented by the following function:

![]()

where Vo(t) is the output voltage, Kp is the voltage constant of the pot in volts per radian (or volts per inch in the case of a linear pot) and θ(t) is the position of the pot in radians (or inches). Since a pot requires an excitation voltage, in order to calculate Vo, we can use

![]()

where Vex is the excitation voltage, θtot is the total travel available of the wiper, and θact is the actual position of the wiper.

Potentiometers can be single turn in which the rotating wiper can move only by 360° or they can also be multi turn in which the rotating wiper can move by several 360° turns. Potentiometers suffer from disadvantages like non-linearity and low life due to the continuous friction between the wiper and the variations in the resistive element.

In addition, the variation in wiper contact between the coil and the wiper can lead to noise in position measurement.

| Read More Topics |

| What is mobile robot? |

| Control system in mechatronics |

| Different types of robot |

| Types of robot control |