INTROCDUCTION to THERMAL ENERGY BASED PROCESSES

In these methods, Thermal energy based process heat energy is concentrated on a small area of the workpiece to melt and vaporize the tiny bits of work material. The required shape is obtained by the continued repetition of this process.

Example:

- Electron Beam Machining (EBM)

- Laser Beam Machining (LBM)

- Plasma Arc Machining (PAM)

ELECTRON BEAM MACHINING (EBM)

INTRODUCTION

In Electron Beam Machining process, high velocity focused beam of electrons are used to remove the metal from the workpiece. These electrons are travelling at half the velocity of light 1.6×108m/s. This process is best suited for micro cutting of materials.

PRINCIPLE

When the high velocity beam of electrons strike the workpiece, its kinetic energy is converted into heat. This concentrated heat raises the temperature of workpiece material and vaporizes a small amount of it, resulting in removal of material from the workpiece.

TYPES OF EBM PROCESS

The following two methods are used in EBM process. Thermal Energy Bassed process

- Machining inside the vacuum chamber.

- Machining outside the vacuum chamber.

CONSTRUCTION AND WORKING OF EBM (Machining Inside the Vacuum Chamber)

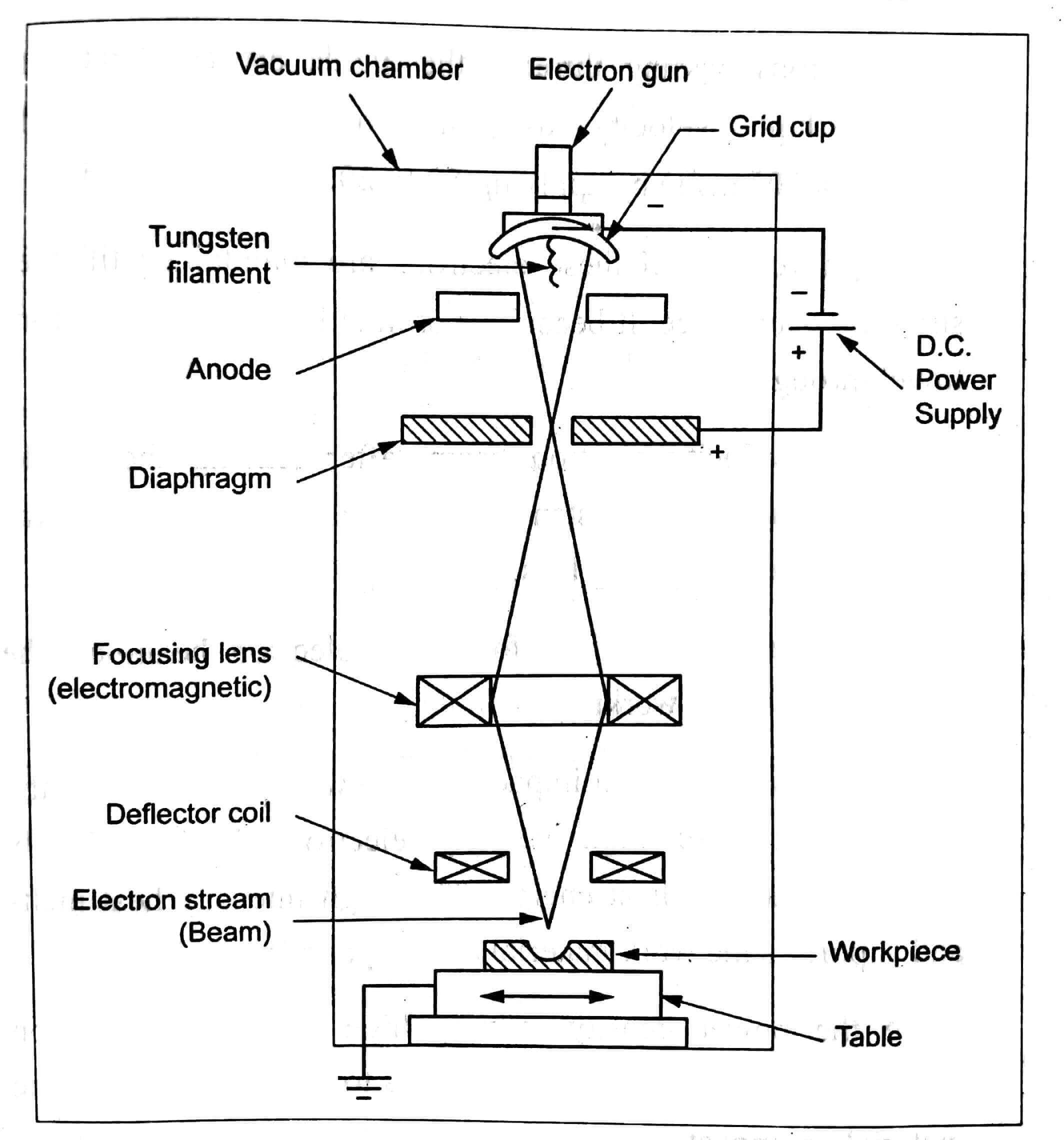

- The schematic arrangement of Electron Beam Machining (EBM)

- It consists of electron gun, diaphragm, focusing lens, deflector coil, work table, etc.

- In order to avoid collision of accelerated electrons with air molecules, vacuum is required. So, the entire EBM setup is enclosed in a vacuum chamber, which carries vacuum of the order 10-5 to 10-6mm of mercury. This chamber carries a door, through which the workpiece is placed over the table. The door is then closed and sealed.

- The electron gun is responsible for the emission of electrons, which consists of the following three main parts.

- Tungsten Filament – which is connected to the negative terminal of the DC power supply and acts as cathode.

- Grid cup – which is negatively based with respect to the filament.

- Anode – which is connected to positive terminal of the DC power supply.

Construction

- The focusing lens is used to focus the electrons at a point and reduces the electron beam upto the cross sectional area of 0.01 to 0.02 mm diameter.

- Due to this high temperature, electrons are emitted from tungsten filament. These electrons are directed by grid cup to travel towards downwards and they are attracted by anode.

- The electrons passing through the anode are accelerated to achieve high velocity as half the velocity of light (1.6×108m/s) by applying 50 to 200 kV at the anode.

- The high velocity of these electrons are maintained till they strike the workpiece. It becomes possible because the electrons travel through the vacuum.

- The high velocity electron beam, after leaving the anode passes through the tungsten diaphragm and then through the electromagnetic focusing lens.

- Focusing lens are used to focus the electron beam on the desired spot of the workpiece.

- When the electron beam impacts on the workpiece surface, the kinetic energy of high velocity electrons is immediately converted into the heat energy. This high intensity heat melts and vaporizes the work material at the spot of beam impact.

- Since the power density is very high (about 6500 billion W/mm2), it takes a few micro seconds to melt and vaporise the material on impact.

- This process is carried out in repeated pulses of short duration. The pulse frequency may range from 1 to 16,000 Hz and duration may range from 4 to 65,000 microseconds.

- By alternately focusing and turning off the electron beam, the cutting process can be continued as long as it is needed.

CHARACTERISTIC OF EBM PROCESS

| Accelerating voltage : 50 to 200kV

Beam current : 100 to 1000µA Electron velocity : 1.6×108m/s Power density : 6500 billion W/mm2 Medium : Vacuum (10-5 to 10-6 mm of Hg) Workpiece material : All materials Depth of cut : Upto 6.5 mm Material removal rate : Upto 40 mm3/s Specific power consumption : 0.5 to 50 kW |

ADVANTAGES OF EBM PROCESS

Electron beam machining has the following advantages:

- It is an excellent process for microfinishing (milligram/s).

- Very small holes can be machined in any type of material to high accuracy.

- Holes of different sizes and shapes can be machined.

- There is no mechanical contact between the tool and workpiece.

- It is a quicker process. Harder materials can also be machined at a faster rate than conventional machining.

- Electrical conductor materials can be machined.

- The physical and metallurgical damage to the workpiece are very less.

- This process can be easily automated.

- Extremely close tolerances are obtained.

- Brittle and fragile materials can be machined.

DISADVANTAGES (LIMITATIONS)

- The metal removal rate is very slow.

- Cost of equipment is very high.

- It is not suitable for large workpiece.

- High skilled operators are required to operate this machine.

- High specific energy consumption.

- A little taper produced on holes.

- Vacuum requirements limits the size of workpiece.

- It is applicable only for thin materrials.

- At the spot where the electron beam strikes the material, a small amount of recasting and metal splash can occur on the surface. It has to be removed afterwards by abrasive cleaning.

- It is not suitable for producing perfectly cylindrical deep holes.

| S.NO | Special characteristics of laser beam |

Cutting process Characteristics |

| 1. | It can be focused to maximum intensity or to minimum intensity as needed. | Metal removal rate is maximum to minimum. |

| 2. | It can be moved rapidly on the workpiece. | Cutting of complex shapes. |

| 3. | It is projected on the workpiece at particular distance from the lens. | Remote cutting over long stand-off distances. |

| 4. | Dedicated to an online process. | Re-routing is not necessary. |

| 5. | Power is shared on a job | Two or move cuts simultaneously. |

MACHINING APPLICATIONS OF LASER

A laser has a wide range of machining applications.

Laser in Metal Cutting

A laser beam can be used for cutting metals, plastics, ceramics, textile, cloth and even glass, when its surface is coated with radiation absorbing material such as carbon. Normally, laser cutting starts by drilling a hole through the workpiece, then moving along a pre-determined path of the shape yo be cut. Steel, titanium, nickel and plastics can be cut easily by using laser beam. But cutting of aluminium metal and copper is very difficult, since these metal tends to absorb the applied heat. The cutting speed of the laser depend on the material being cut, its thickness, physical characteristics and the output power of the laser beam. Laser has an additional in cutting complex shapes with sharp corners and slots.

Laser in Drilling – Thermal Energy

Laser drilling was one of the first practical applications of laser technology in industry and the demand for laser drilling is increasing.

Hole drilling by laser is a process of melting and vaporizing unwanted materials by means of narrow pulsed laser operating at 3 to 95 pulses/s. Due to melting and vaporization process, high accuracy is not possible in laser drilling. So, laser drilling is not suited for deep hole drilling and for producing perfectly cylindrical holes.

Laser drilling is used in watch jewels, diamond dies and other machined parts for various industries where a particularly high level of precision is not demanded.

Laser drilling is used in aircraft-turbine industry to make holes for air bleeds, air cooling or the passage of other fluids. It is also used for making holes in hypodermic needles, automotive fuel plates, various lubrication devices, holes in tungsten carbide tool plate, holes in baby bottle nipples, relief holes in pressure plugs, thermal energy.

Laser in Welding – Thermal Energy

In this process, a laser beam is focused on spot where the two parts are to be welded.

Laser beam welding requires more precise control of the input laser power than in the case of drilling.

Laser welding is especially useful when it is essential to control the size of the heat affected zone, to reduce the roughness of the welded surface and to eliminate mechanical effects. It is generally used for welding multilayer materials.