As we have discussed already, the torque of an engine crankshaft varies considerably throughout the working cycle, due to variations in the crank positions, the pressure in the cylinder and the inertia force on the piston and connecting rod. If the value of the crankshaft torque, the turning moment T is plotted against the crank angle θ, the diagram so obtained is called a turning moment diagram.

we shall discuss the turning moment diagram for various types of engines, functions of flywheel, and its design characteristics.

What are Turning Moment Diagram?

- The turning moment diagram is the graphical representation of the turning moment (T) for various positions of the crank (θ).

- It is plotted on cartesian coordinates, in which the turning moment (T) is taken as the ordinate (Y-axis) and the crank angle (θ) as abscissa (X-axis).

- As T = Ft x r, a plot of Ft Vs θ is identical to a turning moment diagram is known as crank effort diagram.

- The area of turning moment diagram for a particular cycle represents the workdone during the cycle of operation. Because the workdone is the product of the turning moment and the crank angle.

Turning Moment Diagram for a Single Cylinder Double Acting Steam Engine

As already discussed in Section before, the turning moment on the crank shaft is given by

where FT = Crank pin effort,

FP = Piston effort,

r = Radius of crank

l = Length of the connecting rod,

n = l/r and

θ = Angle turned by the crank from inner dead center (IDC).

From the above expression, it is clear that the value of turning moment (T) varies with the variation of the crank rotation angle (θ). If the value of T is plotted against θ, the diagram so obtained is called a turning moment diagram.

When the crank moves from O to I, energy required is OIAP while the energy produced is OAI. Therefore the deficiency of energy is OPA. So the engine speed decreases during this revolution. Similarly, when the crank moves from I to J, the energy required and developed are the areas IACJ and LABCJ respectively. Thus surplus, excess energy is area ABC which increases the speed of the flywheel. Here the flywheel stores this excess energy (equal to area ABC) and delivers it back to the engine when there is deficiency of energy.

In the similar way, when the crank moves from J to K, more energy (equal to area JCEK) is taken from the engine than is developed (equal to area JCD plus area DEK). This loss of energy is represented by the area CDE. To overcome this deficiency of energy, the flywheel gives up some of its stored energy and thus the speed decreases during this period.

Similarly, during the period of crank travel from K to L, excess energy is again developed and is stored in the flywheel and the speed of the engine increases. During the crank. travel from L to H, the loss of energy is made up by the flywheel and the speed again decreases.

Turning Moment Diagram for a Single-Cylinder Four-Stroke I.C. Engine

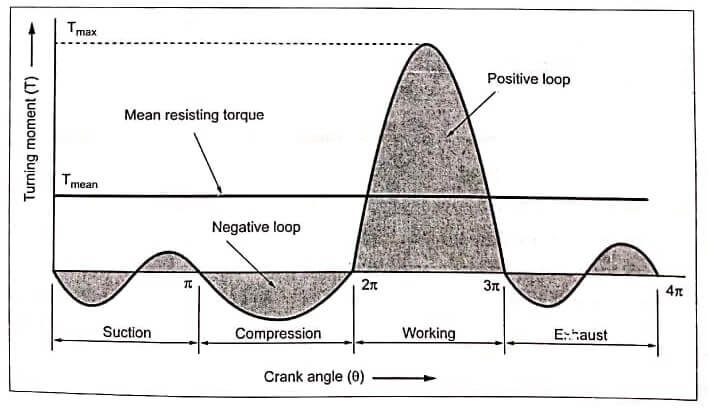

Fig shows the turning moment diagram for a single cylinder four stroke internal combustion engine. We know that in a four stroke IC engine, the diagram repeats itself after every two revolutions (720° or 4π radians) of the crank.

It can be seen from the diagram that the turning moment is positive only during the expansion stroke. Because we know that in a four stroke IC engine, the power is obtained during the expansion stroke only. During the other strokes, suction, compression and exhaust strokes, the energy is absorbed and that’s why the turning moment is negative for all these three strokes.

Turning Moments Diagram for a Multi Cylinder Engine

Fig shows the turning moment diagram for a multi cylinder engine. For multi cylinder engines, the total turning moment (crankshaft torque) at any instant is equal to the sum of the turning moments developed by each cylinder at the instant. That is the reason why the multi cylinder engines have less fluctuation in the turning moment diagram than that for a single cylinder engine.

Other Turning Moment Diagrams : The turning moment diagram for some of the common engines are given Fig.

Uses of Turning Moment Diagrams : The three main uses of turning moment diagrams are: To determine the workdone per cycle and power developed: The area under the turning moment diagram represents workdone per cycle. This area multiplied by number of cycles per second gives the power developed by the engine.

To determine the mean torque and the fluctuation of energy : By dividing the area of the turning moment diagram (workdone per cycle) with the length of the base (the angle turned during the cycle), the mean torque (T mean) can be obtained. By plotting T mean on turning moment diagram, the fluctuation of energy can be determined.

To find the diameter of the crankshaft : The maximum ordinate of the turning moment diagram gives the maximum torque to which the crank shaft is subjected to. This enables to find the diameter of the crank shaft.

To design the flywheel : More importantly, the fluctuation of energy (determined from turning moment diagram) helps to design the size of the flywheel required.

Flywheel

- A flywheel serves as a mechanical reservoir for storing mechanical energy. Its function to store the energy during the period when the supply of energy is more than the requirement, and to give away the same when the requirement of energy is more than the supply.

- A flywheel does not maintain a constant speed, it simply reduces the fluctuation of speed. In other words, a flywheel a controls the speed variations caused by the fluctuation of the engine turning moment during each cycle of operation.

- Applications : Flywheels are provided in engines and fabricating machines such as presses, shearing machines, riveting machines, punching machines, steel rollers, crushers.

Illustration

For example, in I.C Engines, the energy is developed during expansion or power stroke which is much more than the engine load and no energy being developed during other (suction, compression and exhaust) strokes. The excess energy developed during power stroke is absorbed by the flywheel and releases it to the crankshaft during other strokes in which no energy is developed. Thus, it reduces the fluctuation in the speed of engine. The function of flywheel is continuous from cycle to cycle.

It may be pointed out that when the flywheel absorbs energy, its speed increases and when it releases energy, the speed decreases. Hence a flywheel does not maintain a constant speed, it simply reduces the fluctuation of speed.

Flywheel Vs Governor

As discussed above, the flywheel does not maintain a constant speed, it simply reduces the fluctuation of speed. It does not control the speed variations caused by the varying load. But governor regulates the speed of an engine when there are variations in the load. The differences between flywheel and governor are tabulated in before chapter.

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”Why flywheels are needed in forging and pressing operations?” img_alt=”” css_class=””] In both forging and pressing operations, flywheels are required to control the variations in speed during each cycle of an engine. [/sc_fs_faq]

| Read More Topics |

| Radial spring governor |

| Governor vs flywheel |

| Whirling or critical speed of shafts |