Uses of dielectric in capacitor

The dielectric materials used in capacitors may be in vacuum or gaseous form, liquid form, solid – liquid mixed or solid form.

Examples

Gaseous dielectrics – Air, Hydrogen, Nitrogen, Sulfur hexa fluoride, etc

Liquid dielectrics – Synthetic oils [(i.e) Askarels, Pyranol] Mineral oils [(i.e) Transformer oil, Cable oil]

Solid dielectrics – Ceramics, Glass, Mica, etc.,

Film dielectrics – Polystrene, Teflon, Polyethylene etc.

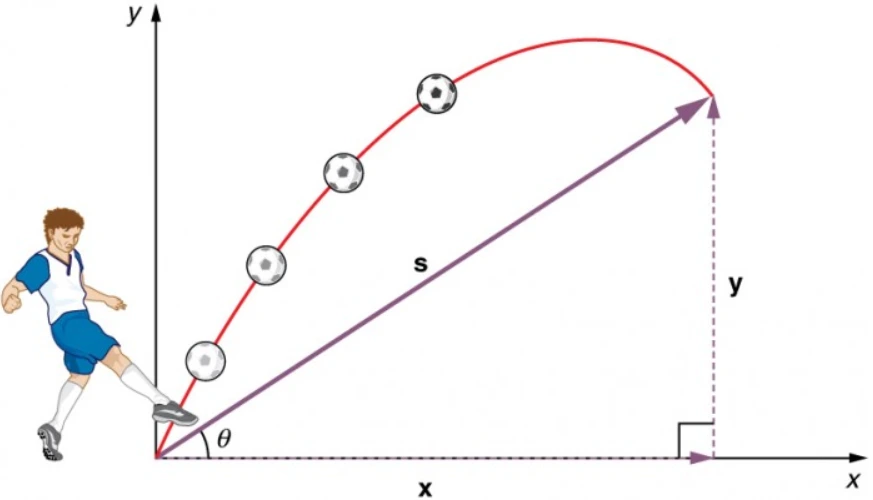

The capacitance of a capacitor varies inversely with the separation of the plates, in other words, with the thickness of the dielectrics. The capacitance of capacitor is given by ![]()

where, ε = dielectric constant of the medium

A = surface area of the plates

d = distance of separation between the plates

Types of capacitor

Capacitor can be classified into three types viz.,

-

- Power capacitors

- Electrolytic capacitors and

- Ceramic capacitors

1.Power Capacitors

- In power capacitors tissue paper and/or polypropylene films are used as dielectrics. This insulation system is filled with mineral oil or synthetic liquids.

2. Electrolytic Capacitors

- The electrolytic capacitors are produced in two forms namely wet and dry forms. The wet type consists of an aluminum can filled with an electrolytic solution of ammonium borat of sodium phoshat. This can form the negative electrode, while the positive electrode is made from corrugated aluminum foil placed in electrolyte.

- The dry type capacitor is made from two very thin aluminium foil strips separated from one another by two layers of circulating paper saturated with a electrolytic paste of glycol and ammonium tetraborate. Now a days tantalum pallet capacitor with sulphuric acid as electrolyte is used.

Advantages

- Electrolytic capacitor are smaller in size with large value of capacitance.

- It has very good dielectric strength (109 V/m )

- The leakage current very low even at 85°C

- The solid electrolyte has good capacitance stability at high temperature and the capacitor charges instantaneously on the application of voltage.

3. Ceramic Capacitors

The ceramic materials have been used for many years as electrical insulators. There are three types of ceramic capacitors.

- Low-loss permittivity type: These are usually made from steatite (commonly known as talc) with permittivity approximately ’ 8 ‘. This is fluxed with one of the feldspar or preferably an alkali-free flux such as Witherite (BaCO3).

- Medium permittivity type: Here the dielectric used is Titania (TiO2) , the alkaline earth titanates (MTiO3) . The dielectric constant of this type of capacitors varies from 70-100.

- High permittivity type: The main advantage of this type of capacitor is possibility of obtaining a large capacitance in a small volume. Permittivities of 1000 – 5000 can be obtained with certain limitations. The dielectric material used is Barium titanate.

The ceramic capacitors are available in variety of shapes such as tube, rectangular, disc etc.

Advantages

i) Ceramic capacitors are able to withstand severe working conditions upto 1200°C .

ii) Because of their inertness they retain their shape and physical characteristics even at high voltages under normal working conditions.

Uses of Dielectric in Power and Distributing Transformer

The dielectric materials used in power and distributing transformers must possess the following properties.

- Good electrical properties to withstand the power frequency voltages and impulse over voltages.

- Good mechanical properties to withstand fabrication and handling during manufacture and electromagnetic forces during overload, short circuit and normal operating conditions.

- Good thermal stability and low ageing effect.

The dielectric materials used in various transformer part is mentioned in the following table.

| S. No | Transformer parts | Dielectric |

| 1. | Low voltage coil to ground and high voltage coil to low voltage coil. | Thick radial spacers or tubes made-up of press board, paper, glass fabric, paper filled plastic laminates and porcelain. |

| 2. | Turn to turn, layer to layer, coil to coil. | Organic enamel, paper, glass tapes, kraft paper, glass fabric, press board, varnished paper. |

| 3. | Fluid (used as insulator and coolant) | Mineral oil, air, nitrogen. |

| 4. | Bushings | Porcelain, phenolic bonded tubes. |

| Read More Topics |

| Bardeen Cooper Schrieffer Theory |

| Introduction to superconductivity |

| Charge densities in a semiconductor |