METALLIC GLASSES

Metallic glasses or Glassy metals are non – crystalline (amorphous) alloys with an atomic configuration similar to molten liquid. It has the short range of atomic order. Metallic glasses share the properties of both glasses and metals. Further they are all strong, ductile, malleable, opaque and brittle.

The first metallic glass was produced by Pol Duwez in 1957.

Glass transition temperature

It is an important parameter for the preparation of metallic glasses. It is defined as the temperature at which the liquid like atomic structure is obtained into a solid. The value of glass transition temperature for metallic alloys is about 20°C to 30°C .

Methods of production of Metallic Glasses

Metallic glasses are manufactured by the following methods. They are,

- Twin roller technique

- Melt extraction technique

- Melt spinning technique

Principle

In all these methods “Splat quenching” or “Rapid quenching” principle is used to manufacture metallic glasses directly from the molten alloy.

Splat quenching or Rapid quenching : (Quenching means sudden cooling)

It is the technique in which the molten alloys are very rapidly cooled, at the rate of 106 Kelvin per Second, by highly conducting massive rollers rotating at high speeds to give ribbons of metallic glasses.

1.Twin roller system

In this technique, the molten alloy is passed through two rollers rotating in opposite directions.

In this technique, the fast moving roller sweeps off molten droplet into a strip from a solid rod.

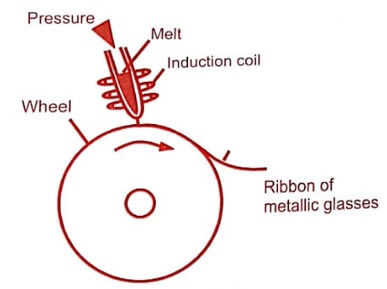

It is the most commonly used technique. This device consists of a disc made up of copper which is rotated at a high speed. A refractory tube having a fine nozzle at the bottom of the tube is placed over the spinning disc and it is filled with alloy.

An induction heater is attached with the tube to melt the alloy under helium atmosphere.

The molten alloy is ejected through the nozzle and the ejection rate may be increased by increasing the gas pressure. Thus the ribbon form of metallic glass is formed over the rotating roller.

Fig (1)

Thickness of the ribbon may be varied by increasing or decreasing the speed of the rotating roller.

Types of Metallic Glasses

The metallic glasses are classified into two types.

- Metal – Metalloid Glasses

- Metal – Metal Glasses

1. Metal – Metalloid Glasses

The first class of metallic glasses is from transition metals ( Fe, Co, Ni) Metalloid (B, Si, C, P) and so they are called metal-metalloid glasses.

2. Metal-Metal Glasses

- Nickel – Niobium (Ni – Nb)

- Magnesium – Zinc (Mg – Zn)

- Copper – Zirconium (Cu – Zr )

- Hafnium – Vanadium (Hf – V) alloys

Applications of Metallic glasses

- Metallic glasses are used as reinforcing elements in concrete, plastic and rubber.

- Metallic glasses are used to make pressure vessels and to construct larger fly wheels for energy storage.

- They are used to make accurate standard resistors, Magnetic resistance sensors and computer memories.

- These are used in tape recorder heads, cores of high power transformers and magnetic shields.

- Metallic glasses are used as core in motors.

- These are used to make razor blades and different kinds of springs.

- Metallic glasses can be used as superconductor for producing high magnetic fields and magnetic levitation effect.

- Metallic glasses are used to make containers for nuclear waste disposal and magnets for fusion reactors.

- Metallic glasses are used in marine cables, chemical filters, inner surfaces of reactor vessels, etc.,

- Metallic glasses are very useful to make surgical instruments.

Important Application:

Metallic glasses as transformer core:

Metallic glasses are available in thin sheets therefore the size and weight of the transformer is reduced. Hysteresis loss is directly proportional to the area of the hysteresis loop. The loop area of the metallic glasses is very small and also have high initial permeability. So, the hysteresis loss is almost zero. The eddy current in the core inversely proportional to the resistivity of the core material and directly proportional to the thickness of the lamination of the core. Since the resistivity of the metallic glasses is high and the thickness of the core laminated core is less. Therefore the eddy current loss is very less. Thus metallic glasses used as core material due to small thickness , smaller area, less weight resistivity soft magnetic with low hysteresis and eddy current losses.

| Read More Topics |

| Dielectric constant or relative permittivity |

| Magnetic recording materials |

| Basic definitions of magnetic materials |