Based on the corrosion of metals in the nature of the environment it is classified into two types:

- Dry or chemical corrosion.

- Wet or electrochemical corrosion.

| S.No | Dry or chemical corrosion | Wet or electrochemical corrosion |

| 1 | Occurs in a dry state. | Occurs in the presence of moisture of electrolyte. |

| 2 | Involves direct chemical attack on the metals by environment. | Involves setting up of tiny galvanic cells. |

| 3 | Follows adsorption mechanism. | Follows mechanism of electrochemical reaction. |

| 4 | Corrosion product accumulates in the same spot, where corrosion occurs. Hence, corrosion is uniform. | Corrosion occurs at the anode and products gather at the cathode. |

Dry (or) chemical corrosion

Dry corrosion occurs due to the direct attack of gases such as hydrogen, oxygen, carbon dioxide, hydrogen sulphide etc., on the surface of the metals.

Corrosion occurs due to adsorption mechanism and corrosion products accumulate in the same spot where corrosion occurs.

- Action of dry HC1 on iron surface.

- Tarnishing of silver by H2S gel etc.

The three important types of chemical corrosion are:

- Oxidation corrosion.

- Corrosion by hydrogen.

- Liquid metal corrosion.

(a) Oxidation corrosion:

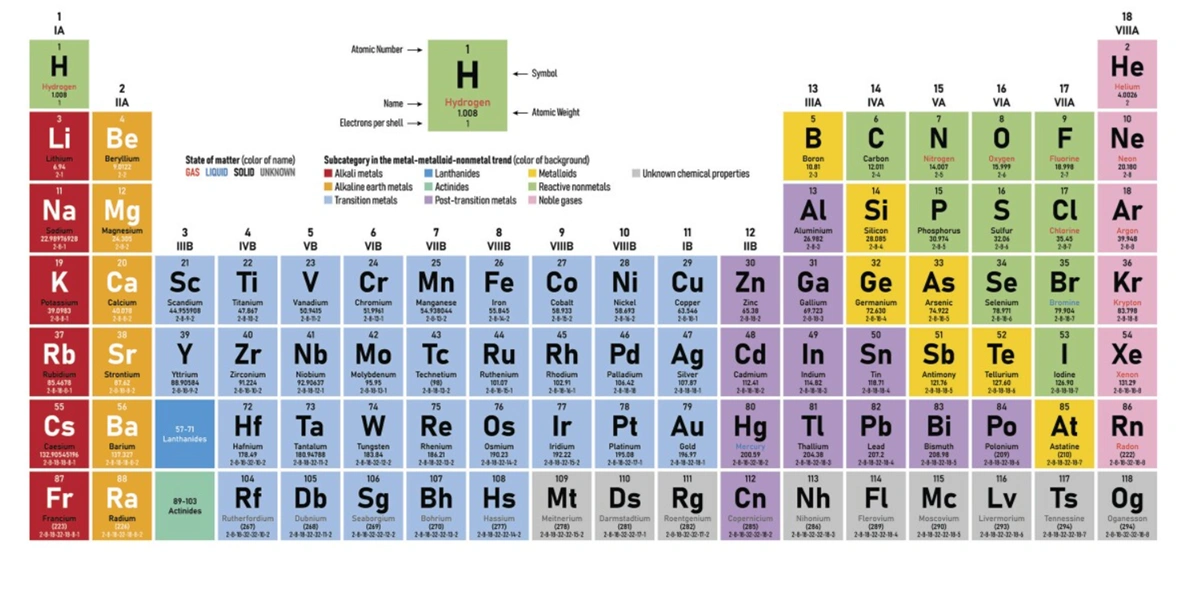

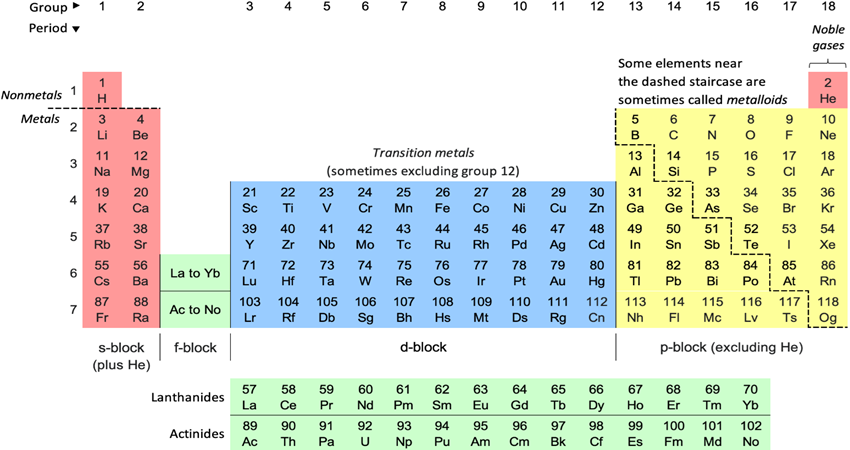

Oxidation corrosion is caused due to the direct attack of oxygen on a metal surface in the absence of moisture. Alkali metals ( Li, Na, K etc.) and alkaline-earth metals ( Be, Ca, Sr etc.) are rapidly oxidised at low temperatures. At high temperatures, almost all metals (except Ag, Au and Pt) are oxidised.

As the temperature increases rate of corrosion also increases.

Mechanism of oxidation corrosion:

When a clean metal surface is exposed to air at room temperature, adsorption of oxygen takes place on the metal surface.

This adsorption is purely physical in character and it is due to the secondary attractive forces between the residual valency of the surface atoms of the metal and that of the oxygen molecule. Oxygen combines with the metal by electron transfer between oxygen and the metal atom.

The metal surface is converted into the monolayer of oxide, which leads to the formation of oxide film.

The reactions in the oxidation corrosion are:

At the metal/scale interface

M → M²+ + 2e–

At the scale / environment interface

½O2 + 2e– → O2

Overall reaction M + ½O2 → MO (Metal oxide)

The nature of oxide film formed on the metal surface plays an important role in oxidation corrosion.

Metal + Oxygen → Metal oxide

This metal oxide produced forms a thin film on the metal surface. The nature of the film decides the extent of corrosion. as detailed below.

(i) Stable: A stable film can get adhered tightly to the parent metal surface. Hence, such a film cannot allow the penetration of oxygen to the underlying metal. Hence, it behaves as a protective coating and prevents further corrosion.

E.g., oxides of Al, Sn, Pb, Cu, Pt etc., are stable in nature.

(ii) Unstable: Metals like Ag, Au and Pt form unstable oxides. These oxides formed decompose back into the metal and oxygen.

Metal oxide → Metal + Oxygen

Thus, the above metals do not undergo corrosion.

(iii) Volatile: The oxide film volatilises as soon as it is formed. It leaves fresh metal surface for further continuous attack.

E.g., Molybdenum oxide (MoO3).

(iv) Porous: Metal oxide having pores and cracks can allow the penetration of oxygen to the underlying metal, thereby the corrosion continues till the entire metal is completely converted into its oxide.

Pilling-Bedworth ratio:

Pilling and Bedworth proposed that the oxidation resistance is related to the volume ratio of oxide film formed and metal consumed.

The ratio of the volume of the oxide formed to the volume of the metal consumed is called Pilling-Bedworth ratio. This can be mathematically represented as

![]()

where M = mass of the metal oxide, m = atomic weight

d = density of the metal, D = density of the scale

n = number of metal atoms in a molecular formula of the scale (n = 2 for Al2 O3)

R < 1 = oxide is porous

R > 1 = oxide is non-porous and protective,

The ratio R indicates the volume of oxide formed from a unit volume of metal.

Some example of Pilling-Bedworth ratio is discussed as follows:

In case of alkali and alkaline earth metals such as Na,Mg,Ca etc., the volume of oxide film formed on the surface is less than the volume of metal consumed.

Hence, the oxide layer formed is non-protective and porous.

In case of heavy metals such as Pb, Sn etc., the volume of the oxide film formed on the metal surface is greater than the volume of the metal consumed.

Hence, the oxide layer formed in this case is protective and non-porous in nature.

In the case of noble metals such as Au, Pt etc., metallic state is more stable than that of the oxide state. Hence, oxidation corrosion is not possible in this case.

In certain cases, the oxide film formed is volatile in nature and hence a fresh metal is exposed for further attack. This leads to continuous corrosion.

Examples for this type:

- Chlorine gas attacks the surface of tin to form stannic chloride, which is a volatile liquid.

- Molybdenum oxide (MoO3) is volatile in nature.

(b) Corrosion by H2 gas

(i) Hydrogen embrittlement

The process of formation of cracks and blisters on the metal by hydrogen gas when the metal comes into contact with H2S is known as hydrogen embrittlement.

This type of corrosion normally occurs at low-temperature conditions, when a metal is exposed to hydrogen environment. The atomic hydrogen diffuses into the metal voids and forms molecular hydrogen.

2 (H+) → H2

Collection of these gases in the voids develops very high pressure, which leads to cracking and hence decreases the strength of the metal.

(ii) Decarburisation

The process of decrease in the carbon content of steel is called decarburisation.

At high temperature, molecular hydrogen decomposes to atomic hydrogen.

H2 → (H+) + (H2).

When steel is exposed to this environment, carbon in the steel reacts with atomic hydrogen.

C + 4H → CH4

Hence the carbon content in steel decreases. Collection of methane gas in the voids of steel develops high pressure and causes cracking. Thus, steel loses its strength.

(c) Liquid metal corrosion

It is due to the chemical action of flowing liquid metal at high temperatures over a solid metal or an alloy. This type of erosion corrosion is due to:

- dissolution of solid metal by liquid metal (or)

- internal penetration of the liquid metal into the solid metal.

This leads to the weakening of the solid metal. Such type of corrosion is noticed in devices used for nuclear power generation.

Wet (or) electrochemical corrosion

This type of corrosion occurs under two conditions:

- When two dissimilar metals are in contact with each other in the presence of an aqueous solution.

- When a metal is exposed to an electrolyte.

The wet corrosion involves two steps.

Oxidation or metal dissolution: This occurs always at anode.

M → Mn+ + Ne–

Reduction: Reduction reaction is dependent on the nature of the environment.

2H+ + 2e– → H2

(a) Acidic environment: Here hydrogen gas is evolved at the cathode.

2H+ + 2e– → H2

(b) Neutral environment: In neutral or slightly alkaline medium, hydroxide ions are formed at the cathode.

1 /2 O2 + H2 O + 2e– → 2OH–

Hydrogen evolution type corrosion: (in acidic medium)

In the hydrogen evolution corrosion, the environment is acidic in nature especially in the industrial atmosphere.

For example, consider a metal Fe (iron) which was exposed to aerated, corrosive water.

At the anode : The removal of electrons from the iron surface takes place.

Fe → Fe2+ + 2e–

At the cathode : The electrons flow from larger anode area to the smaller cathode are as where they react with H+ ions to produce hydrogen gas.

2H+ + 2e−⟶ H2

Metals with higher negative electrode potential will always have a tendency to liberate hydrogen when they come in contact with acidic atmosphere.

Absorption of oxygen-type corrosion: (in neutral medium)

The oxygen absorption type electrochemical reaction takes place on the surface in neutral parts or weekly alkaline environment with oxygen.

Rusting of iron in neutral aqueous solution of electrolytes in the presence of atmospheric oxygen is a common example of this type of corrosion.

The surface of iron is usually coated with a thin film of iron oxide. However, if this iron oxide film develops some cracks, anodic areas are created on the surface and the rest of the metal part acts as cathode.

At the anode : Dissolution of iron takes place with the liberation of electrons.

Fe → Fe2+ + 2e–

At the cathode : The liberated electrons flow from anodic to cathodic areas through iron metal, where electrons are taken up by dissolved oxygen.

1 /2 O2 + H2 O + 2e– → 2OH–

The resulting ions Fe2+ and OH− combine together to form Fe(OH)2.

Fe2+ + 2OH– → Fe (OH)2

In the presence of excess of oxygen, ferrous hydroxide is easily oxidised to ferric hydroxide (rust).

4Fe (OH)2 + O2 + 2H2O → 4Fe(OH)3

This product, called yellow rust actually corresponds to Fe2O3H2O Fig.

Difference between chemical corrosion and electrochemical corrosion

| S.No | Chemical corrosion | Electrochemical corrosion |

| 1 | It occurs in dry condition. | It occurs in the presence of electrolyte or moisture. |

| 2 | It involves the direct chemical attack of the metal by the dry gases present in the environment. | It involves setting up of large number of tiny galvanic cells. |

| 3 | It is based on adsorption mechanism. | It is based on the mechanism of electrochemical reactions. |

| 4 | It is a slow process. | It is a fast process. |

| 5 | Corrosion products accumulate at the same place where corrosion occurs. | Corrosion occurs at the anode, but products accumulate near the cathode. |

| 6 | E.g., Tarnishing of silver. | E.g., Rusting of iron. |

| Read More Topics |

| Electrochemistry – Solved problems |

| Consequences of corrosion – chemistry |

| Measurement of single electrode potential |