Induction motors are the workhorses of modern industry. Whether you’re in manufacturing, HVAC, or water treatment, chances are your systems rely on these robust, low-maintenance motors to keep things spinning.

Why Efficiency Matters in Today’s Power-Hungry World

When energy costs are on the rise and going green is not a choice, enhancing motor efficiency is no longer an option. From reducing energy expenditures to reducing your carbon footprint, increasing the efficiency of your motors just makes sense.

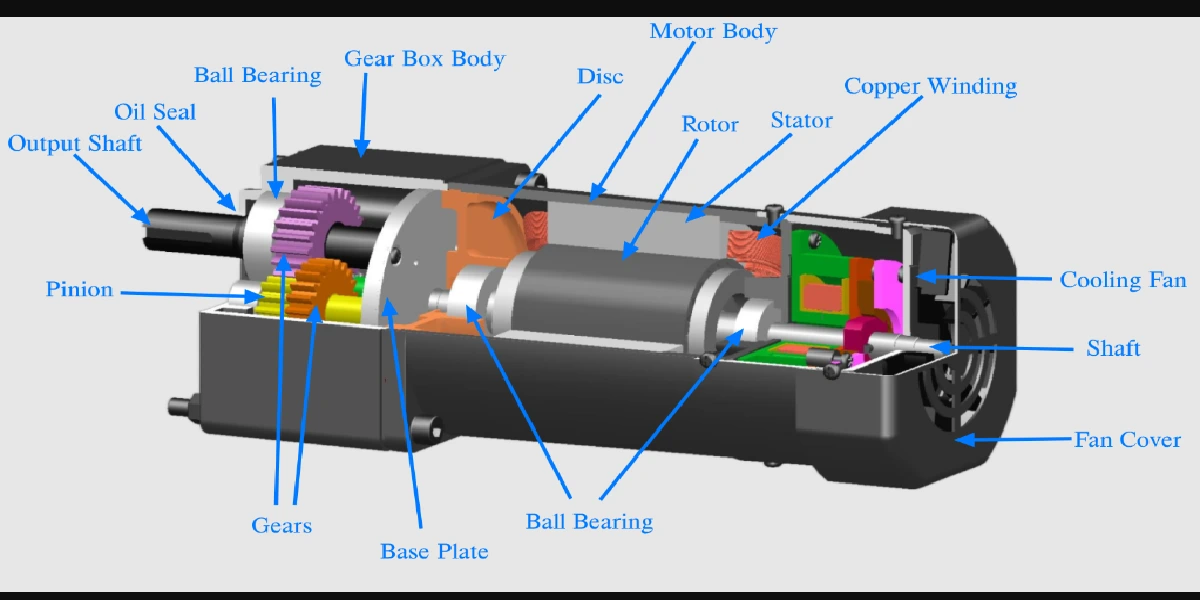

Getting to Know Induction Motor Fundamentals

Types of Induction Motors

Squirrel Cage Motor: Simple, tried-and-true, and maintenance-free.

Wound Rotor Motor: Provides greater control, utilized in high-load applications.

How an Induction Motor Functions

Electricity generates a magnetic field in the stator. This revolving field produces a current in the rotor, which creates torque. Low-tech, but genius.

Energy Flow and Places of Power Loss

Stator Losses

Rotor Losses

Iron Losses

Friction and Windage Losses

The Requirement for Efficiency Maximization

Industrial Power Consumption Facts

The International Energy Agency (IEA) reports that electric motors consume 45% of electricity worldwide and that induction motors comprise most of it.

Effect on Operating Expenses and Carbon Footprint

One percent gain in motor efficiency can mean thousands of dollars in yearly savings—not to mention the effect on the planet.

Step-by-Step Guide to Efficiency Improvement

Step 1 – Proper Motor Selection for Application

Employing a 20HP motor for a 10HP application wastes energy. Always opt for a motor capable of meeting the load requirement.

Step 2 – Selecting High-Efficiency Motor Designs

Seek out IE3 or IE4-rated motors. These high-efficiency motors will be more expensive initially but pay huge dividends in the long run.

Step 3 – Optiming Voltage and Frequency Supply

Uneven voltage decreases motor life and efficiency. Employ power conditioners or stabilizers to maintain clean input.

Step 4 – Proper Load Matching

Motors ought to operate at 75-100% of nameplate load. Anything below = wasted power.

Step 5 – Routine Maintenance and Monitoring

- \tClean air grills

- \tInspect winding insulation

- \tWatch for irregularities in current draw

Step 6 – Applying Variable Frequency Drives (VFDs)

VFDs vary motor speed to follow the load. Best for HVAC and pumping systems with changing demand.

Step 7 – Cooling and Ventilation Improvements

A motor that is properly cooled will run better. See that ventilation is not obstructed and filters are clean.

Step 8 – Lubrication Best Practices and Techniques

Apply the proper type and quantity of lubricant. Over-lubrication is worse than under-lubrication.

Conclusion: Increasing induction motor efficiency is not rocket science—its sensible engineering. By following the step-by-step instructions outlined here, you’re not only saving electricity, but also saving money, minimizing downtime, and maximizing your motor’s lifespan. Small adjustments pay off big time. So why wait? Begin optimizing your motors today and see your efficiency soar.

Read also: Bidirectional Converters For EVs and Energy Storage