A cam and follower is a rotating or oscillating machine clement having a curved outline Or a curved groove. It gives a predetermined specified motion to another element called the follower which is in contact. A general example is the camshaft of an automobile which takes the rotary motion of the engine and translates it into the reciprocating motion necessary to operate the intake and exhaust valves of the cylinders.

A cam mechanism consists of three elements: the cam, the follower, and the frame as shown in image. The cam is a projecting part of a rotating wheel or shaft. The follower is in direct contact with the cam and transmits motion to another

body. The frame of the machine supports the bearing surfaces for the cam and for the follower.

The cam has a very important function in the operation of many classes of machines, especially those of the automatic type, such as printing presses, shoe machinery, textile machinery, gear-cutting machines, and screw machines. In any class of machinery in which automatic control and accurate timing are paramount, the cam is an indispensable part of mechanism.

Working Principle of Cam and Follower

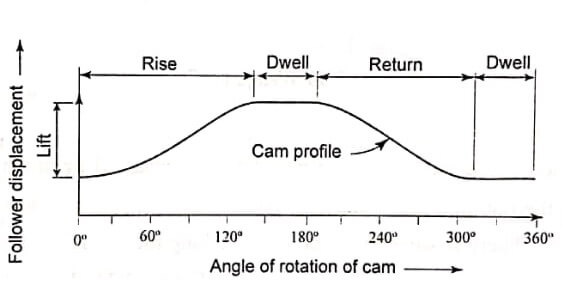

When the cam turns through one motion of cycle, the follower executes a series of events consisting of rises, dwells, and returns. Rise is the motion of the follower away from the cam center; dwell is the motion during which the follower is at rest; and fall is the motion of the follower toward the cam center.

When the cam rotates about its axis, a specific motion to the follower is obtained which repeats with each revolution of the cam. The motion of the cam is represented by a graph drawn between follower displacement and angle. The angular displacement of the cam is taken in x-axis while the y-axis represents the angular or the linear displacement of the follower. The tracer point of the follower rises off the prime circle by the rise. It will remain for a while (or) at the same position which is called “dwell“. Then return to the prime circle, and also remain at rest in a second dwell before repeating the cycle.

In the cam profile illustrated in Figure, the rise section describes how quickly the follower will be lifted and the fall section describes how quickly the follower will fall. During the dwell section of the cam, the follower will remain at the same level for a significant period of time. So, dwell of the cam is defined as the resting period of the follower with uniform diameter of the cam for certain angle.

Types of Cams

The cam may be of various shapes. The variety of different types of cam and follower systems that one can choose from is types of quite broad. The most common cams according to cam shapes are discussed here.

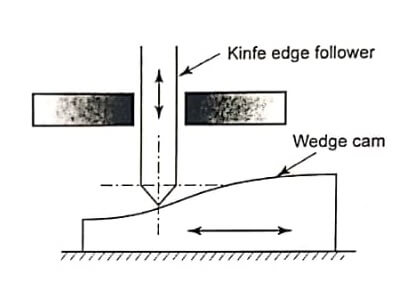

Translating or Wedge or flat cams

A wedge cam is used where the translational motion of the wedge is converted into the reciprocating motion of the follower. Figure shows the arrangement of the wedge cam and the knife edge follower.

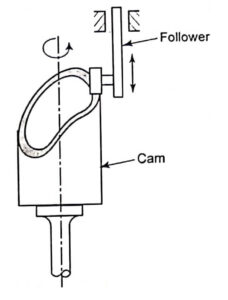

Plate or disc cams

Plate or disc cams are also called radial cams. They are made of a thick plate of the required shape and size. As the cam rotates the follower is pushed up and down. There is some external force pushing the follower back down, so that it remains in contact with the cam profile. Figure shows this type of cam with flat foot follower.

Cylindrical Cams

This cam and follower system is slightly different to the plate cams. The cylindrical or barrel cam consists of a rotating cylinder with a helical (screw shaped) groove in its curved surface. A follower with a tapered roller end is located in the groove. Cylindrical cams are used when motion has to be transmitted parallel to the axis of rotation of the cam. As the cylinder turns, the follower moves in a straight line parallel to the axis of the rotation barrel cam. Figure shows this type of cam with oscillating follower.

Box or Grooved Cams

A groove is milled in the face of cam discs as shown in Figure. As the cam rotates, a follower located in the groove has its motion guided by the groove. This type of cam is called a box cam.

End cam

This cam has a rotating portion of a cylinder as shown in Figure. The follower translates or oscillates, whereas the cam usually rotates. The end cam is rarely used because of the cost and the difficulty in cutting its contour.

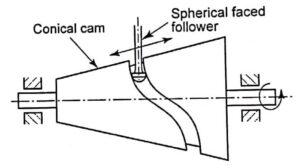

Conical cam and Followers

In a conical cam, a frustum of cone has a circumferential helical contour cut on the outer periphery which rotates about its axis. Figure shows the conical cam with spherical follower which is reciprocating in a direction parallel to the cone axis.

Globoidal cams

Globoidal cams are similar in operation as that of conical cams but it has convex or concave surfaces instead of conical surfaces. A circumferential contour is cut on the surface of rotation of the cam to make motion to the follower. The follower

generally oscillates as in cylindrical cam.

Types of Cam Follower

Knife edge follower

This is the simplest type, is not often used due to the rapid rate of wear. When it is adopted, it is usually for reciprocating motion, running in slides and there is considerable side thrust, this being a component of the thrust from the cam. Figure shows the knife edge follower.

Flat foot or mushroom follower

This type of follower has a flat surface to contact with the cam. The problem of wear is not as great as with the knife-edge follower, since the point of contact between the cam and follower will move across the face of the follower according to the change of shape of the cam. Figure shows this type follower. These types of followers are used as valve in IC engines.

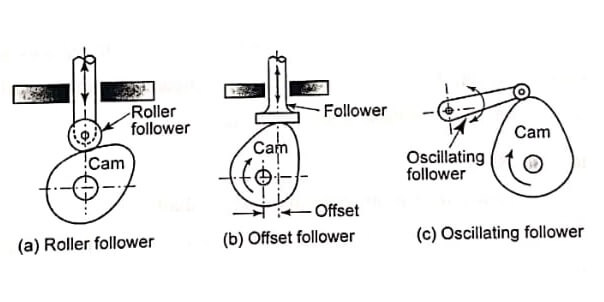

Roller follower

This type of follower has roller attached with it which is in contact with the cam and rolls over it. This eliminates the problem of rapid wear since the sliding effect is largely replaced by a roller action. Figure (a) shows this type follower.

Offset follower

If the line of movement of the roller follower or flat faced follower is offset from the centre of rotation of the cam, the follower is known as an offset follower. Figure (b) shows this type follower.

Oscillating followers

Oscillating followers are pivoted at a suitable point on the frame and oscillate as the cam makes the rotary motion as shown

rotary motion as shown in Figure (c). There are four types of oscillating followers depending upon the shape of the end of the follower:

- Spherical faced oscillating follower

- Flat faced oscillating follower

- Roller faced oscillating follower

- Edge oscillating follower

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”What is cam dynamics?” img_alt=”” css_class=””] Cam dynamics is the study of cam follower system with considering the dynamic forces and torques developed in it. [/sc_fs_faq]

- See More : Natural frequency of free transverse vibration

- See More : Basic communication system

- See More : Coordinate measuring machine