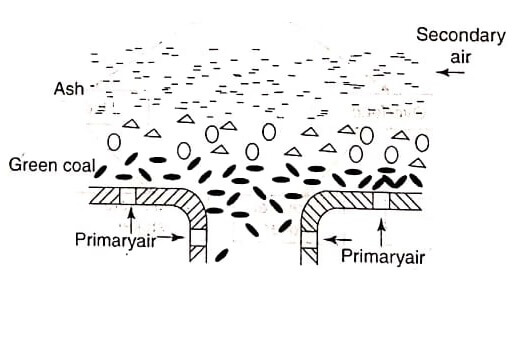

In this type of stoker, the fuel and air move in the same direction. In this type of stokers, the air entering the holes in the grate comes in contact with the raw coal. Then the air is mixed with formed volatile matter and passed through the ignition and then entered into the region of incandescent coke. The reactions takes place in underfeed stokers similar to the overfeed stokers.

After the gases coming out of raw fuel bed, it passes through a region of incandescent ash on the surface of the fuel and finally is discharged to the furnace.

It is very much suitable for semi bituminous and bituminous coals having high volatile matter.

Underfeed Stokers Classification

Single retort stoker

In this type, the fuel is placed in large size hopper at the front of the furnace. The coal fed from the hopper goes to the horizontal trough.

Through the tuyers, the air is supplied for mixing the coal with air.

The ash and clinkers are collected in the ash plate. The feeding capacity of this type is about 100 to 2000kg per hour. To increase the burning capacity, the multi retort stoker is used.

Multi retort stoker

In this, the coal falling from the hopper is pushed forward during the inward stroke of stoker arm.

Each rotor is filled with a reciprocating ram for feeding and pusher plates for the uniform distribution of coal.

The distributing rams (pushers) slowly move the entire coal down the length of stoker. The ash formed is collected at the other end.

The length of stroke of pushers can be varied according to the load. The primary air enters the fuel bed through the wind box which is below the stoker. The partly burnt coal moves on the extension grate.

The low pressure air is entered into the extension grate. A thinner fuel bed on the extension requires low pressure air. So, the air from the main wind box is regulated through dampers.

The numbers of retorts may vary from 2 to 20 and burning capacity of about 300kg to 2000kg per hour per retort.

Advantages of underfed stokes :

- Part load efficiency is high.

- It has high thermal efficiency

- They are self cleaning grates

- Variety of coals can be used

- It is more suitable for variable load conditions

- Tuyers, grate bars and retorts are hot subjected to high temperature.

- Smokeless operation.

- It is more suitable for high volatile and low ash content coals.

- It can be used for all refractory furnaces.

- The fuel bed is free from clinker.

Disadvantages of underfed stokes :

- Space requirement is high.

- Initial cost is high.

- Clinkers formation affects its smooth running.

- It is not suitable for low grade feeds.

- See More : Overfeed stokers Classification

- See More : Coal cleaning equipment

- See More : Blow moulding process

- See More : Press working terminology