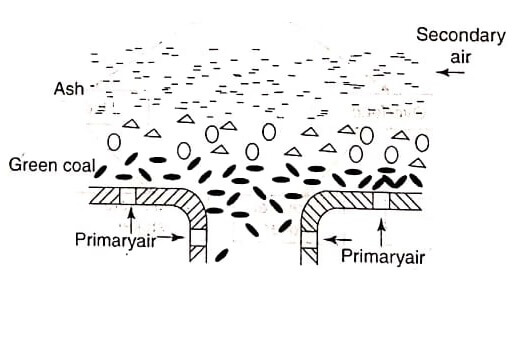

In case of overfeed stokers, the coal is fed on the grate above the point of air admission.

Working principle : In this type of fuel firing, the primary air enters the grate from the bottom. The air passing through the grate is heated by absorbing the heat from the ash and grates itself. So, the grate is cooled.

Then the air a passes through a layer of incandescent coke and the oxygen in the air is reacted with coke to form CO2. The rate of carbon oxidation depends upon the rate of air supply.

The water vapour present in the air also reacts with coke to form CO, CO2 and H2. The gases leaving the fuel bed contain the N2, CO2, CO, H2 and H2O. Then additional air is supplied to burn the combustible gases.

The burnt gases entering the boiler contain N2, CO2, O2 and H2O and some CO, if the fuel burning is not completed.

A chain grate stoker

It consists of an endless chain which forms a support for fuel bed. The chain travels over two sprocket wheels one at the front and the other at the rear of furnace. The front sprocket is connected with variable speed mechanism.

The traveling chain receives coal at its front end through a hopper and carries it into the furnace.

The ash containing a small amount of combustible materials is carried over the rear end of the overfeed stokers and deposited in the ash pit. The air required for combustion enters through the air inlets situated below the grate.

The secondary air is supplied above the grate. The combination of primary and secondary air produces a high turbulence for complete combustion.

Spreader stoker

In this system, the coal is fed through the feeder. The feeder arrangement has rotating drum with blades. The speed of the feeder can be changed as per the level of the plant. From the feeder, the coal is dropped over the spreader distributor which spreads the coal over the furnace.

The spreader consists of a rapidly rotating shaft carrying blades. These fast rotating blades with the coal particles are coming from the feeder and throw it into the furnace.

Advantages:

- Variety of coal can be used to burn in this stoker.

- Cooling of ash is easier because of incoming air is under the ash.

- Less operating cost.

- It is very useful for fluctuating loads.

Disadvantages:

- It is not suitable for large size coal.

- It requires dust collecting equipment

- See More : Lathe fixture or turning fixture

- See More : Blow mounding process

- See More : Press working terminology