This is a very high pressure supercritical water cooled reactor which operates above the thermodynamic critical point of water to give a thermal efficiency about one third higher than today’s light water reactors. The supercritical water (25 MPa and 510-550°C) directly drives the turbine without any secondary steam system. Passive safety features are similar to those of simplified boiling water reactors. Fuel is Uranium oxide, enriched in the case of the open fuel cycle option. However, it can be built as a fast reactor with full actinide recycle based on conventional reprocessing.

The Supercritical water cooled reactor (SCWR) is a Generation IV reactor concept that uses supercritical water as the working fluid. SCWRs are basically light water reactors (LWRs) operating at higher pressure and temperatures with a direct, once-through cycle. It operates on a direct cycle like boiling water reactor (BWR), but since it uses supercritical water not to be confused with critical mass as the working fluid will have only one phase present, like the pressurised water reactor (PWR). It could operate at much higher temperatures and pressure than both current PWRs and BWRs.

Supercritical water cooled reactor (SCWRs) are promising advanced nuclear systems because of their high thermal efficiency about 45% vs. about 33% efficiency for current light water reactors (LWR) and considerable plant simplification.

A key issue in natural circulation is constituted by the stability of the flow mainly when two phase conditions are concerned and when the feedback with neutron kinetics is possible.

The main mission of the SCWR is generation of low cost electricity. It is built upon two proven technologies, LWRs, which are the most commonly deployed power generating reactors in the world, and supercritical fossil fuel fired boilers, a large a number of which are also in use around the world.

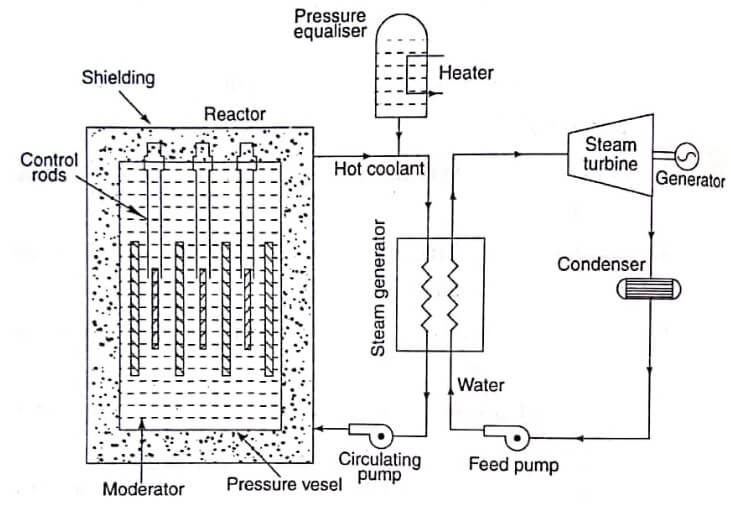

A supercritical water reactor is light water cooled and moderated reactor having an unusual core design using both natural and highly enriched fuel. The nuclear power plant using a pressurised water reactor is shown in fig.

The main components of the reactor are

(i) Reactor.

(ii) Pressuriser

(iii) Heat exchanger

(iv) Coolant pump.

The components of the secondary circuit of pressurised water plant are similar to those in a normal steam station (Steam turbine, condenser, feed pump, and heat exchanger).

The coolant in the primary circuit is pumped to the reactor core. The coolant absorbs heat energy which is liberated during nuclear fission in the reactor core. The hot coolant passes through the heat exchanger where the coolant transfers heat energy to the feed water and steam is generated. The water from the heat exchanger is again circulated by the coolant pump. The water becomes radioactive in passing through the reactors. Therefore, the entire primary circuit including heat exchanger must be shielded to protect the operating personnel. The steam in the turbine is not radioactive and need not be shielded.

The pressure in the primary circuit should be high so that the boiling of water takes place at high pressure. This enables water to carry more heat from the reactor. The ‘pressurising tank keeps the water at about 14MN/m² so that it will not boil. Electric heating coil in the pressuriser boils the water to form the steam which is collected in the dome as shown in fig as more steam is forced into the dome by boiling, its pressure rises and pressurises the entire circuit. To reduce the pressure, water spray is used to condense the steam.

A supercritical water reactor can produce only saturated steam. If there is a need of superheated steam, separate furnace should be provided.

Advantages:

- Water technology well known.

- Water which is cheaply available in plenty is used for coolant, moderator and reflector.

- Water is cheap.

- Water is very effective moderator of neutron energy

- The reactor is compact and high power density (65kN/litre).

- Number of control required is less.

- Easily available natural Uranium is used as fuel.

- Steam is not contaminated by radiation. Hence, maintenance of turbine, feed heaters and condenser is normal.

- This reactor allows to reduce the fuel cost extracting more energy per unit weight of fuel.

- Water has high heat capacity.

- Negative temperature coefficient.

- Ordinary leakage can be tolerated.

- Fission products are contained not circulated.

- Radioactivity of coolant is short lived if kept pure.

- Conversion ratio may be high.

- Superheating steam in separately fired superheater is possible.

- Appreciable fast fission effect attainable.

Disadvantages:

- Water must be highly pressurized to achieve even reasonably high temperature without boiling.

- High pressure requires stronger reactor vessel and hence capital cost is high.

- Thermal efficiency of the plant is low since low pressure is maintained in secondary circuit.

- Fuel element fabrication is expensive.

- The temperature is limited in metallic fuel elements.

- Fission product activity in the core builds up to high a level.

- Reprocessing of fuel is difficult since, it is affected by radiation.

- It is necessary to shutdown the reactor for fuel charging which requires couple of month time.

- Pure hot water is highly corrosive, requires special materials for the primary loop.

- Fuel must be at least slightly enriched.

- Heat exchanger and control rods required.

- Large excess reactivity at operating temperature.

- Uneven heating is caused when gamma radiation pass through the pressure vessel. Hence, thermal stresses involved make difficulty in design.

- Heat transfer only moderately efficient.

- Fuel reprocessing a difficult task.

- Low volume ratio of moderator to fuel makes fuel element design and insertion of control rods difficult.

- The corrosion problems are more severe as the pressure is high.

- Rector must be shut down to unload and reload core.

- Water would flash to steam in case of rupture of primary loop.

- Water reacts with Uranium, thorium, and structural metals under certain conditions.

- Low thermal heads make heat exchanger, pumps and piping large.

- Hot channel factors are significant.

| Read More Topics |

| Micro hydro power plant |

| Layout of nuclear power plant |

| CANDU |

| Cooling towers and types |