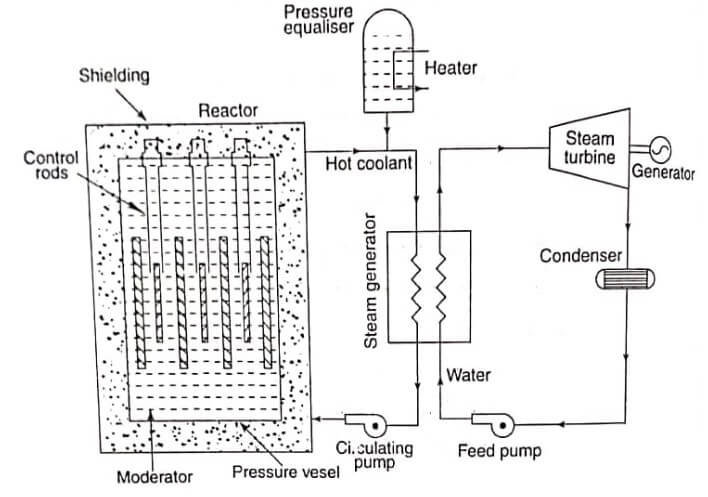

A pressurised water reactor is a light water cooled and moderated reactor having an unusual core design using both natural and highly enriched fuel. The nuclear power plant using a prescribed water reactor is shown in fig.

The main components of the reactor are:

- Reactor.

- Pressuriser

- Heat exchanger

- Coolant pump.

The components of the secondary circuit of pressurised water plant are similar to those in a normal steam station (Steam turbine, condenser, feed pump, and heat exchanger).

The coolant in the primary circuit is pumped to the reactor core. The coolant absorbs heat energy which is liberated during nuclear fission in the reactor core. The hot coolant passes through the heat exchanger where the coolant transfers heat energy to the feed water and steam is generated. The water from the heat exchanger is again circulated by the coolant pump. The water becomes radioactive in passing through the reactors. Therefore, the entire primary circuit including heat exchanger must be shielded to protect the operating personnel. The steam in the turbine is not radioactive and need not be shielded.

The pressure in the primary circuit should be high so that the boiling of water takes place at high pressure: This enables water to carry more heat from the reactor. The pressurising tank keeps the water at about 14MN/m² so that it will not boil. Electric heating coil in the pressuriser boils the water to form the steam which is collected in the dome as shown in fig as more steam is forced into the dome by boiling, its pressure rises and pressurises the entire circuit. To reduce the pressure, water spray is used to condense the steam.

A pressurised water reactor can produce only saturated steam. If there is a need of superheated steam, separate furnace should be provided.

Advantages

- Water which is cheaply available in plenty is used for coolant, moderator and reflector.

- The reactor is compact and high power density (65kN/litre).

- Number of control required is less.

- Easily available natural uranium is used as fuel.

- Steam is not contaminated by radiation. Hence, maintenance of turbine, feed heaters and condenser is normal.

- This reactor allows to reduce the fuel cost extracting more energy per unit weight of fuel.

Disadvantages

- High pressure requires stronger reactor vessel and hence capital cost is high.

- Thermal efficiency of the plant is low since low pressure is maintained in secondary circuit.

- Fuel element fabrication is expensive.

- Reprocessing of fuel is difficult since, it is affected by radiation.

- It is necessary to shutdown the reactor for fuel charging which requires a couple of month time.

- Uneven heating is caused when gamma radiation pass through the pressure vessel. Hence, thermal stresses involved make difficulty in design.

- Low volume ratio of moderator to fuel makes fuel element design and insertion of control rods difficult.

- The corrosion problems are more severe as the pressure is high.

- See More : Layout of nuclear power plant

- See More : Nuclear power plant fundamentals

- See More : Steam power plant layout