This is an example for absorption type hydraulic dynamometer.

Principle:

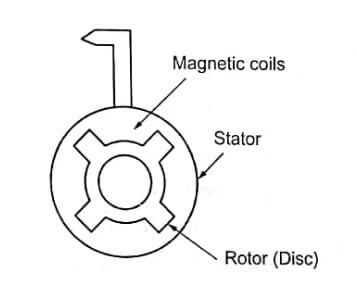

When a conducting material moves through a magnetic flux field, voltage is generated, which causes current to flow. If the conductor is a wire forming, a part of a complete circuit current will be caused to flow through that circuit, and with some form of commutating device a form of A.C. or D.C generator may result.

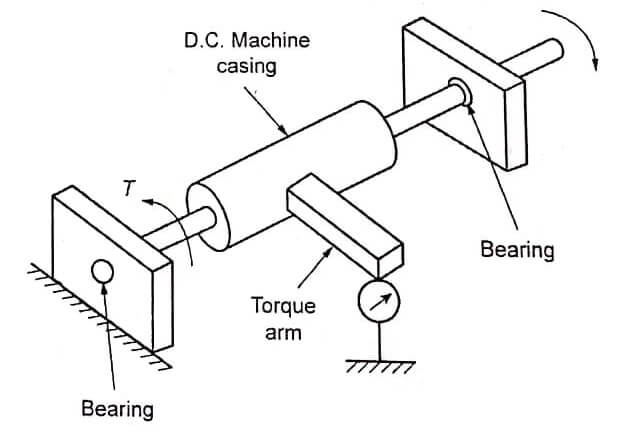

An eddy current dynamometer is shown in fig. It consists of a metal disc or wheel which is rotated in the flux of a magnetic field. The field if produced by field elements or coils is excited by an external source and attached to the dynamometer housing which is mounted in trunnion bearings. As the disc turns, eddy currents are generated. Its reaction with the magnetic field tends to rotate the complete housing in the trunnion bearings. Water cooling is employed.

Hydraulic dynamometer

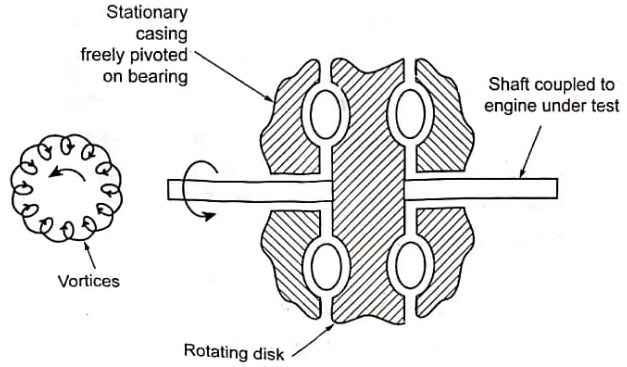

It uses fluid friction rather than dry friction for dissipating the input energy. It consists of rotating disc and a stationary casing. The rotating disc is keyed to the drive shaft of the prime mover and it revolves inside the stationary casing.

The casing is mounted on antifriction bearings and has a brake arm and a balance system attached to it. This bearing allows the casing to rotate freely except for the restraint imposed by the brake arm. The casing is in the form of two halves. One of which is placed on either side of the rotating disc. The semi elliptical placed in the casing match with corresponding grooves inside the rotating disc to form chamber. The stream of water flow is maintained in this chamber.

When the brake is operating, the water follows a helical path in the chamber. Vortices and eddy current are set up in the water and tend to turn the dynamometer cannons in the direction of rotation at the engine shaft. This tendency is resisted by the brake arm and balance system that measures the torque.

The amount of braking is controlled by varying either the amount of water and its pressure or the distance between the rotators disc and the stationary casing. Maximum absorption is obtained with the casing full, and minimum absorption with its minimum amount of water required to keep the shaft seals lubricated. The amount of water circulated must be sufficient to prevent the formation of steam, since such action would cause momentary unloading. Power absorption by a hydraulic accelerometer varies approximately as the cube of rotational speed and as the fifth power of rotor diameter.

Advantages of hydraulic accelerometer

- Less space required for high absorption capacity.

- Low cost

- No additional water is required for cooling.

- See More : Alignment tests on pillar type

- See More : Hydraulic and pneumatic systems

- See More : Micro hydro power plant

- See More : High energy rate forming process