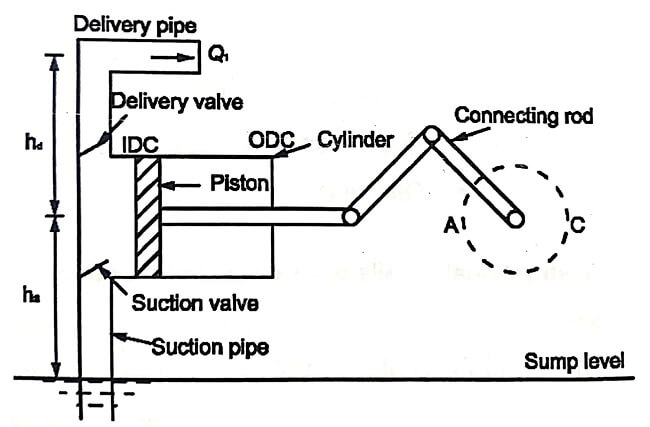

In a single acting reciprocating pumps, liquid acts on one side of the piston only. Image shows a single acting reciprocating pump which has one suction pipe and one delivery pipe. It is usually placed above the liquid level in the sump.

When the crank rotates clockwise from dead centre (IDC) (from A) to outer dead center (ODC) (i.e., C) the piston moves outward to the right and a vacuum is created on the left side of the piston. This vacuum causes the suction valve to open and liquid is forced from the sump into left side of the piston. When the crank is at ODC , the suction stroke is completed and the left side of cylinder is full of liquid.

When the crank rotates from ODC to IDC (i.e., C to A), the piston moves inward to the left and a high pressure is built up in the cylinder. The increased pressure causes the suction valve to close and the discharge valve to open. Thus, the liquid is carried to the discharge tank through the delivery pipe.

The delivery stroke is completed when the crank occupies the ODC position. The suction and delivery stroke are alternatively carried out, and the liquid is pumped from the sump to the discharge tank.

What is the main difference between single acting and double acting reciprocating pump?

In a single acting reciprocating pump, the liquids acts on one side of the piston only whereas in double acting reciprocating pump, the liquid acts on both sides of the piston.

- See More : Pressure control valve

- See More : Directional control valve (DCVs)

- See More : Computer controlled CMM