SRM is a single excited and double salient pole electric motor. It is an electromagnetic and electrodynamic equipment. Switched reluctance motor operating principle is similar to a single-stack variable-reluctance stepping motor. However, design procedures and control strategies in VRM are different from those used in a stepping motor. For example, a SRM requires a rotor position sensor whereas it is not needed in VR stepper motor. SRM is designed for continuous rotation whereas VR stepper motor is designed to rotate in steps. A SRM has concentrated windings an stator poles and no winding on the rotor teeth.

SRM are now finding increasing use in adjustable-speed drives because of the following features.

- This motor is simple in construction with no winding on rotor and simple concentrated coils on stator.

- It can run successfully at high speeds (about 2×105rpm) because of no winding on rotor and rugged rotor construction.

- Stator windings can be cooled easily and efficiently.

- Because of effective stator cooling, the motor dimensions decrease for a given machine rating.

- A SRM can be operated from unidirectional drive circuits, cost of micro and power-electronics is reduced.

- SRM operates successfully, though at reduced output, even if one or more phases are out of circuit due to same fault.

- As these motors can be manufactured with a large number of stator and rotor teeth, they give large torque per unit volume.

Due to above features of SRM drive is used for the general purpose adjustable speed drives. SRM drive can now compete with adjustable – speed do and induction motor drives.

Construction of SRM

Terminal Board

A1°A2° B1° B2° C1° C2°

Stator

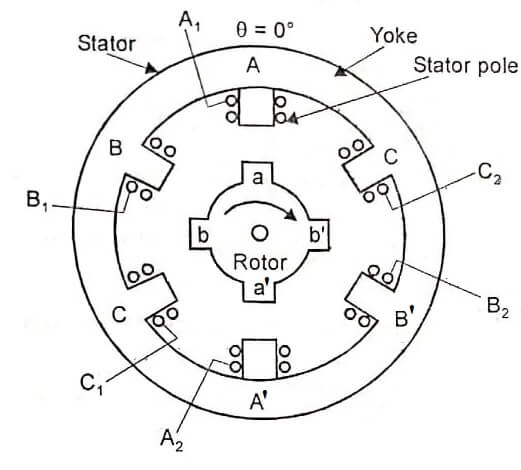

The construction of SRM is shown in figure. Stator is made up of silicon steel stampings with inward projected poles.

The number of poles of the stator can be either in an even number or an odd number. Most of the motors have even number of stator poles.

All these poles carry field coils (or) stator windings. The field’ coils of opposite poles are connected in series such that mmf’s are additive and they are called “phase windings”. Phase windings are connected to the terminals of the motor.

Rotor

The rotor is also made up of silicon steel stampings with, outward projected poles. The rotor shaft carries a rotor position sensor.

The turning on and off operation of the various devices of power semiconductor switching circuitry are influenced by signals obtained from rotor position sensor. Number of poles of the rotor different from the number of stator poles.

Block Diagram of SRM

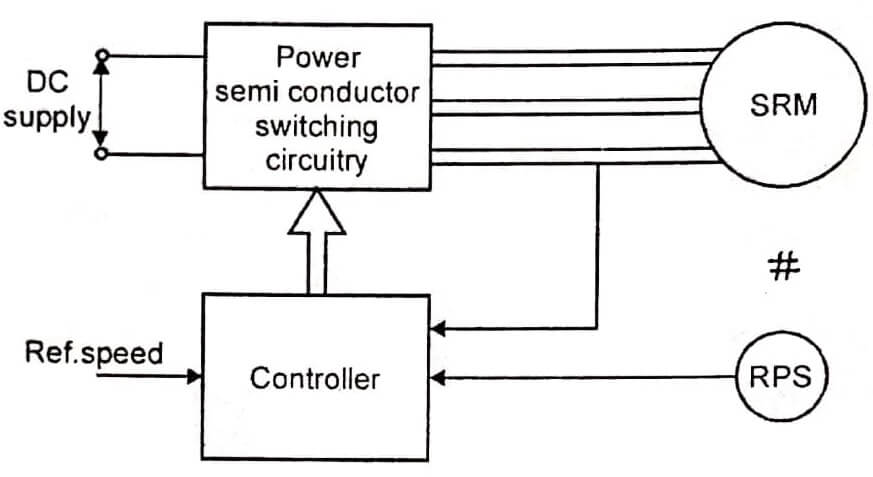

Figure shows the block diagram of SRM: DC supply is given to the power semiconductor switching circuitry, which is connected to various phase windings of SRM.

RPS which is mounted on a shaft of the SRM, provides signals to the controller about the position of the rotor with respect to the reference axis.

Controller collects these information and also reference speed signal and suitably turns on and off the concern power semiconductor devices of switching circuit, such that the desired phase winding is connected to the DC supply. The current signal is also feedback to the controller circuit to limit the motor current within permissible limits.

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”What are the application of SRM?” img_alt=”” css_class=””] Washing machines, Vacuum cleaners, Fans, Future auto mobile applications, Robotics control applications. [/sc_fs_faq]

| Read More Topics |

| Single phase induction motor |

| Three phase transformer connections |

| Transformer rating in kVA |