These galvanometers are of d’Arsonval type having a moving coil suspended between the pieces of a permanent magnet. When an alternating current is passed through the moving coil, an alternating deflecting torque is produced which makes the coil vibrate with a frequency equal to the frequency of the current passing. On account of inertia of the moving parts, the amplitude of vibrations is small. However, if the natural frequency of the moving system is made equal to the frequency of the current, mechanical resonance is obtained and the moving system vibrates with a large amplitude.

The damping is very small in these galvanometers. This is required in order to obtain a sharp resonance curve so that the galvanometer is selective, it gives a very small deflection for alternating currents of frequencies other than the resonant frequency.

Vibration galvanometers are suitable for use at power and low audio frequencies, but they are mainly used at power frequencies. They can be manufactured for fixed frequencies, or they can be provided with tuning devices to cover a range of frequencies.

Construction of Vibration Galvanometers

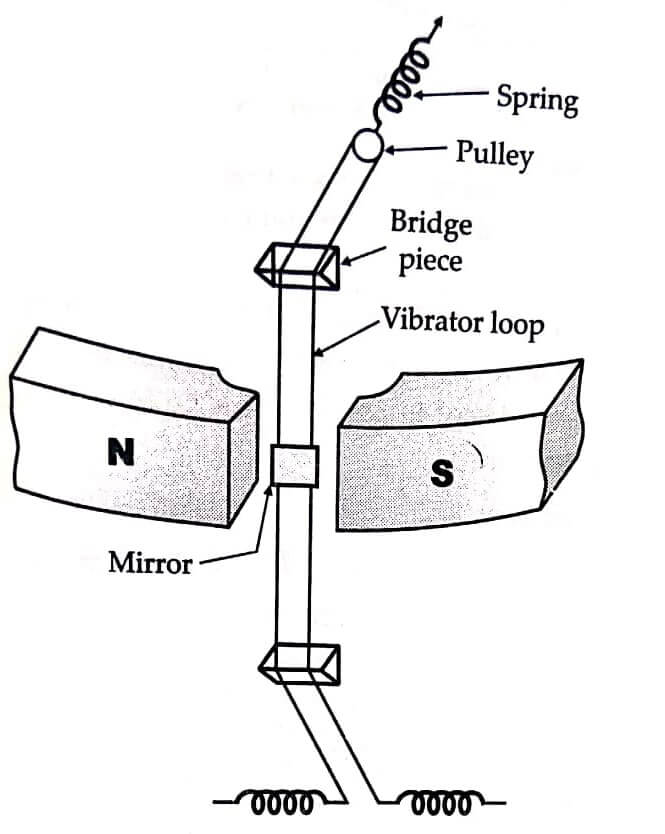

Fig shows the construction of a Duddell’s moving coil vibration galvanometer. The moving coil consists of a fine bronze or platinum silver wire. This wire passes over a small pulley at the top and is pulled tight by a spring attached to the pulley, the tension of the spring can be adjusted by turning a milled head attached to the spring.

The loop of wire is stretched over two ivory bridge pieces, the distance between these pieces is adjustable. When the moving coil vibrates due to passage of a.c., the reflected beam from the mirror throws a band of light upon a scale provided for the purpose.

Tuning – Tuning means adjustment of the natural frequency of the moving system so that it is equal to the frequency of the current passing through the coil.

In the case of Duddell’s galvanometer coarse tuning is done by varying the distance between the bridge pieces. This varies the length of the loop which is free to vibrate and thus varies the natural frequency of the moving system. Fine adjustment of tuning is done by varying the tension of the spring.

When the galvanometer is tuned (when it is under mechanical resonance conditions), the amplitude of vibrations is very large and consequently a very wide band of light is observed on the scale.

| Read More Topics |

| Primary standard of luminous intensity |

| Comparison of deflection |

| Duddell oscillograph element |