Blow moulds are relatively simple in design and construction when the predominant blow moulded products are bottle and container. The blow moulding process are made of aluminum or other lightweight metal. It can be either machined or cast. Requires a high degree of cooling throughout the mould. It requires several vents at parting line and sometimes within the cavity.

Working Principle of Blow Moulding

Blow moulds were relatively simple in design and construction. The predominant blow moulded products are thin walled plastic parts, such as bottles and containers. Blow moulding process is classified into three types.

- Injection Blow Moulding

- Extrusion Blow Moulding

- Stretch Blow Moulding.

Over the three processes, the injection blow moulding is commonly used a blow moulding process. In injection blow moulding, a preformed shape emerged from extrusion called parison is fitted in the nozzle and the compressed air will be blown into it which forms a thin walled parts.

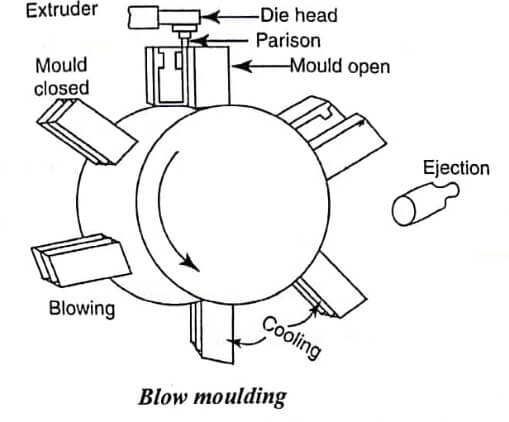

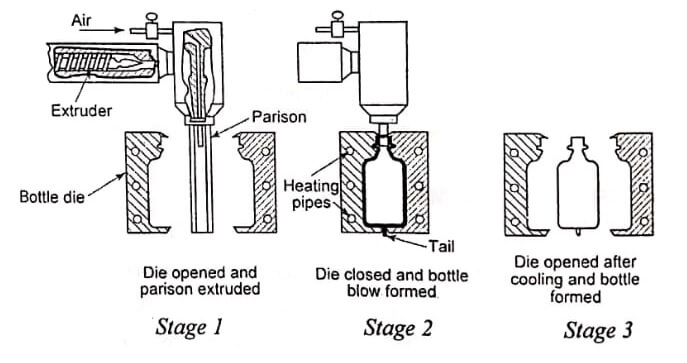

Figure shows the process of injection blow moulding.

The two valves of the mould move towards each other so that the mould closes over the tube. The bottom end of parison is sealed. The compressed air is used to blow the molten plastic into the mould and the tube gets pinched off and also welded at the bottom by the closing moulds.

The air pressure is about 0.7 to 10kg/cm². This air pressure will force the tube against the walls of the mould.

Finally, the component is cooled and the mould is opened to release the components. The blow moulding method ranges from simple manual operation to complicated automatic ones.

In a multilayer blow moulding, multi layer structures are used. Typical examples for multiplayer blow moulding are plastic packing for food and beverage.

Applications

- It is used to produce plastic bottles and toys

- It is used to produce plastic buckets

- Used to produce plastic cans

- It is used to produce plastic barrels

- The hollow containers are produced by this process.

- The multiplayer blow moulding used in cosmetics and pharmaceutical Industries.

- See More : Injection Moulding

- See More : Types of casting process

- See More : Underfeed stoker classification