In cooling towers, the warm water is discharged from the condenser and fed the cooled water back to the condenser. The rate of evaporation of water in cooling tower and subsequent reduction in water temperature depend upon the following parameters.

- The exposive time.

- Amount of water surface exposed.

- Relative humidity of air.

- Velocity of air

- Accessibility of air to various parts of cooling tower.

Types of cooling towers

There are two types as follows

- Wet type

- Dry type

Wet type

The different types of wet cooling towers are

- Atmospheric cooling tower (Natural draft).

- Mechanical draft towers.

Atmospheric or Natural draft cooling tower

In this type of cooling tower, the air flows naturally without fan through tower. It is further classified into

1. Natural draft spray filled tower.

2. Natural draft packed type tower.

3. Hyperbolic cooling tower.

Natural draft spray filled tower

In this type of tower, the air enters through tuyers sides and flows across the unit in a transverse direction. Hot water is allowed to fall over tuyers. It is used for small capacity power plants like diesel power plants. The capacity of this tower varies from 50. to :100litres per minute per m².

Natural draft packed type tower

It is similar to spray filled tower except the water distributing fills which are used to break the water into small droplets. It is rarely used in thermal power plants. The flow of air in this type is also crosswise to the flow of water.

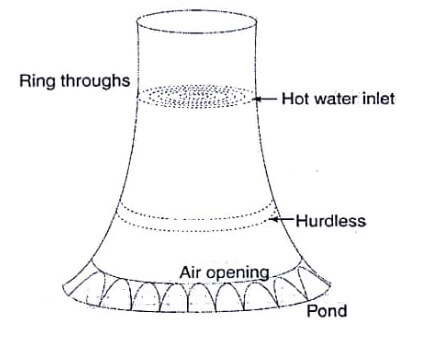

Hyperbolic cooling tower

The hyperbolic cooling tower is a steel reinforced concrete structure and the bottom 10m. above the air intake contains packing over which warm water flows. The operation of the hyperbolic cooling tower is similar to that of other natural draft cooling towers. Similar to that of natural cooling tower in hyperbolic cooling tower, there is no fan used to supply the air. The airflow is created by the chimney action only.

Advantages of this tower:

- Flow of air is created by chimney itself.

- No fans are needed, so power consumption is less.

- It is self supported structure.

- Less ground area required.

Disadvantages:

- Performance varies with seasonal changes.

- Initial cost is high.

Mechanical Draft Cooling System

It requires less space and less piping than natural draft towers. The mechanical draft towers use fans to move the air through the tower instead of depending on natural draft. The mechanical draft cooling towers are classified into two types.

a. Forced draft

b. Induced draft.

The induced draft is again classified into counter flow and cross flow types.

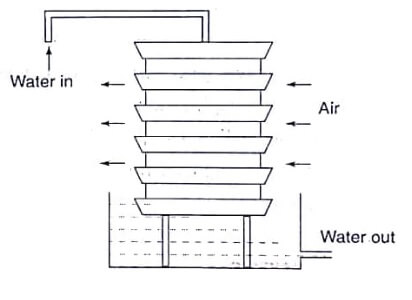

Forced draft tower

In this tower, draught. fan is installed at the bottom of tower. The air is blown up by the fan through the descending water. The hot water from the condenser enters the nozzles. The water is sprayed on the tower filling slots and rising of air cools the waters.

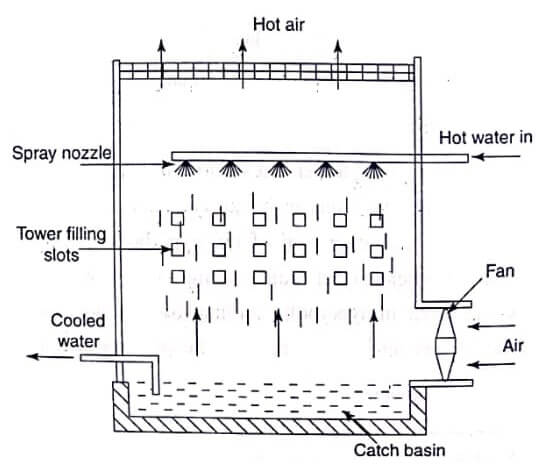

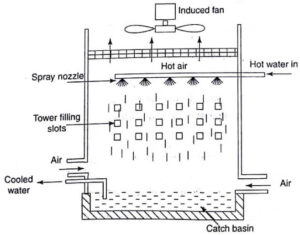

Induced draft cooling towers

In induced draft cooling tower, the draft fan is installed at the top of tower and air is drawn through it. The hot water is sprayed through the nozzle to pass it over the air and the water is cooled. The air is moving in the upward direction to cool the water. The cooling effect of water is done by (1) Evaporation and (2) Heat transfer to the air. The cooling effect is done by about 75% by evaporation. The cooling of

water is shown in fig.

Comparison of forced draft towers and induced draft towers

| Forced draft towers | Induced draft towers |

| It is more efficient | It is less efficient |

| Fan blade erosion is avoided. | Fan blade erosion is there because of wet air. |

| Minimum mechanical equipment. | Noisy operation |

| Fan size is limited to 4 meters | Fan ‘ size about 20m in diameter can be used. |

| Power requirement is high. | Less power requirement |

| It is more safety | Less safety due fan is located at he top of the tower. |

| Initial cost is high. | Initial cost is less. |

Cooling Tower Terms

Approach (A) : It is the difference between the exit temperature of cooling water and the wet bulb temperature of atmospheric air.

Approach (A) = tc2 – twb Where, tc2 = Exit temperature of cooling tower. twb = Wet bulb temperature of atmospheric air

Approach varies from 6°C to 8°C

Range (R) : It is the difference in temperature of the incoming warm water (tc1) and the exiting cooled water (tc2).

R = tc1 – tc2

The range varies from 6 to 10°C

Cooling efficiency

It is the ratio of actual cooling of water to the maximum cooling possible.

ηcooling = Actual coolingMaximum cooling possible = tc1-tc2tc1-twb

Drift

It is fine water droplets entrained and carried by the air.

Dry Cooling Towers

These types of cooling towers are used where water is not available in plenty. In this type of cooling tower, the water flows through finned tubes over which the cooling air is passed. The dry cooling towers are classified into two types.

- Direct type

- Indirect type.

Direct type

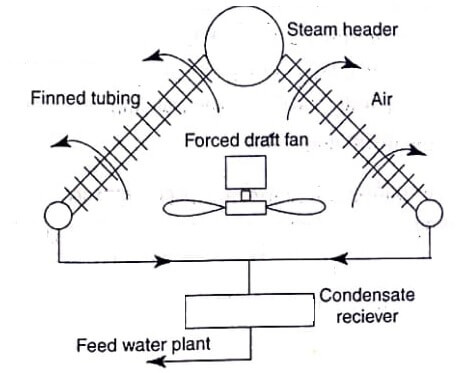

Fig. shows the direct type dry cooling system. In a direct dry cooling tower, the turbine exhaust steam flows into a large steam header and then to a large number of finned tubes.

Indirect type

In indirect dry cooling tower, there are three designs. They are

- Cooling tower using conventional surface condenser.

- Direct contact spray condenser.

- Cooling tower using ammonia as the coolant.

Indirect cooling tower with surface condenser

In this, warm water from the condenser flows through finned tubes and is cooled by atmospheric air flow over the tubes. This is shown in fig. There are two types of heat exchangers used. One is placed in between steam and water in the condenser and other one is placed in between air in the tower and water.

Indirect dry cooling tower with spray condenser

In this type, the exhaust steam enters the open condenser and the water is sprayed into the steam. The part of condensate is received in the receiver as feed water. The remaining part of condensate is fed to the finned tubes.

Indirect dry cooling tower using ammonia

In this system, the ammonia is used in the condenser. The ammonia evaporates in the steam condenser. The ammonia condenser is the dry tower and rejects the heat of the air which is heated.

Finally, the saturated liquid ammonia is pumped back to the condenser. The fig shows the indirect dry cooling tower using ammonia.

| Read More Topics |

| Design of cooling system |

| Internal combustion engine |

| Electroslag welding |