Electrodes: Generally two types of electroslag welding that are solid and metal cored are used. Though solid electrodes are more popular than the metal cored electrodes.

Flux: Flux is the most important consumable material of Electroslag Welding. In its molten state it transforms the electrical energy into heat energy which helps in melting the electrode wire and the base metal to form a weld joint. It is also required to protect the molten weld metal from the atmosphere and to ensure stability. The flux in its molten state is required to conduct electricity but at the same time it should offer sufficient resistance to its flow for generating enough heat to do welding.

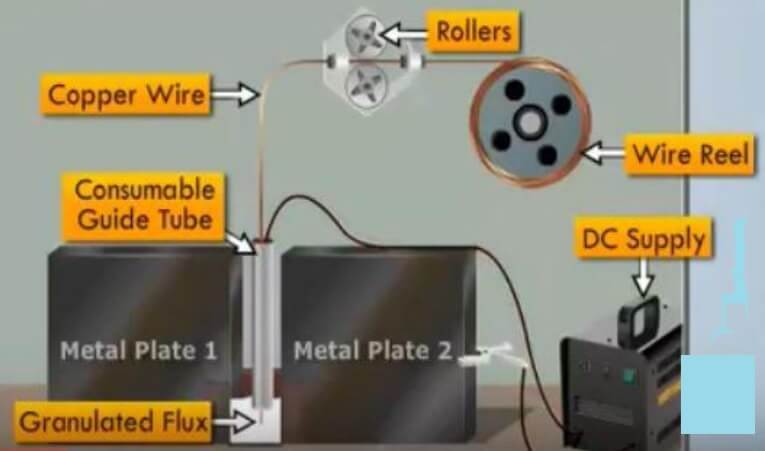

ESW – Working principle

Firstly current flows from welding electrode to base plate. This establishes an arc between electrode and base plate which heats the flux. This heat which is produced during arc formation results in melting the filler metal and deposits into the weld cavity.

Now the cooled copper shoe starts its function of solidifying the filler metal into weld cavity. This this is done to avoid flowing of weld metal outside.

As the filler metal solidifies into weld cavity, the current flows through it. Then it generates heat due to electric resistance. This heat is further used to continue the melting of the filler metal into weld Cavity.

Which means that heat is regenerated, which results in less waste of heat or energy.

Roller arrangement continuously provides the filler metal.

During welding of the metals both copper shoe and feed mechanism moves upward until the whole cavity is formed.

This will create a strong joint in single one pass. The single or multi pass weld is used according to plate thickness.

Electroslag Welding (ESW) Advantages

- Cooling rate is very low so there is no problem of cold cracking.

- There is no problem of slag inclusion or porosity.

- The process is semi-automatic and faster.

- Heavier section can be welded in single pass.

- High productivity can be achieved.

- Low cost for joint preparation.

ESW Disadvantages

- Cooling rate is very low so there is no problem of cold cracking.

- There is no problem of slag inclusion or porosity.

- The process is semi-automatic and faster.

- Heavier section can be welded in single pass.

- High productivity can be achieved.

- Low cost for joint preparation.

Electroslag Welding ESW – Applications

- It is used in heavy industries where plate thickness is up to 80 mm to be joined.

- Welding of thick walled large diameter pipes is done by this welding process.

- Welding of storage tanks is done by it.

- It is used to construct big and thick parts of ships.

| Read More Topics |

| Friction stir welding process |

| Laser beam welding process |

| Solid state welding process |

| Under water welding process |