A design of transformers consists of two windings coupled through a magnetic medium. The two windings work at different voltage level. The two windings of the transformer are called High voltage winding and Low voltage winding. Both the windings are wound on a common core. One of the winding is connected to ac supply and it is called primary. The other winding is connected to load and it is called secondary.

The transformer is used to transfer electrical energy from high voltage winding to low voltage winding or vice versa through magnetic field.

Transformer Construction

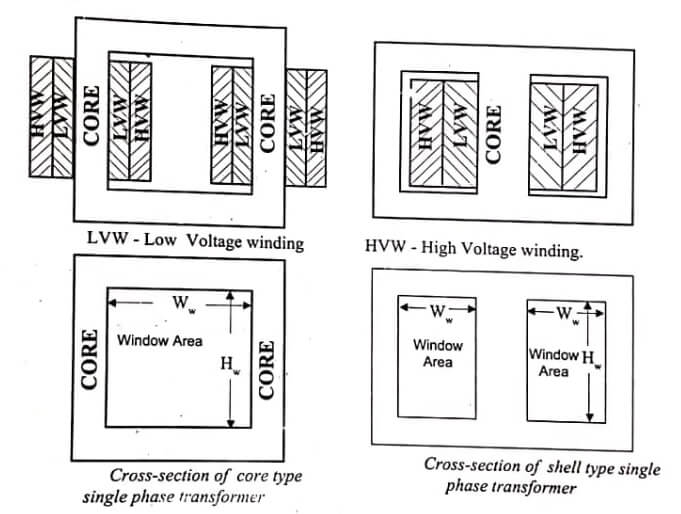

The construction of transformers varies greatly, depending on their applications, winding voltage and current ratings and operating frequencies. The two major types of construction of transformers (used in transmission and distribution of electrical energy) are core type and shell type. Depending on the application, these transformers can be classified as distribution transformers and power transformers.

The transformer is extremely important as a component in many different types of electric circuits, from small signal electronic circuits to high voltage power transmission systems.

The most important function performed by transformers are,

- Changing voltage and current level in an electric system.

- Matching source and load impedances for maximum power transfer in electronic and control circuitry.

- Electrical isolation.

Core type transformer

In core type transformer, the magnetic core is built of laminations to form a rectangular frame and the windings are arranged concentrically with each other around the legs or limbs. The top and bottom horizontal portion of the core are called yoke. The yokes connect the two limbs and have a cross sectional area equal to or greater than that of limbs.

Each limb carries one half of primary and secondary. The two windings are closely coupled together to reduce the leakage reactance. The low voltage winding is wound near the core and high voltage winding is wound over low voltage winding away from core in order to reduce the amount of insulating materials required.

Shell type transformer

In shell type transformers the windings are put around the central limb and the flux path is completed through two side limbs. The central limb carries total mutual flux while the side limbs forming a part of parallel magnetic circuit carry half the total flux. The cross sectional area of the central limb is twice that of each side limbs.

Comparison of core and shell type transformer

| Core Type | Shell Type |

| Easy in design and construction. | Comparatively complex. |

| Has low mechanical strength due to non bracing of windings. | High mechanical strength. |

| Reduction of leakage reactance is not easily possible. | Reduction of leakage reactance is highly possible. |

| The assembly can be easily dismantled for repair work. | It cannot be easily dismantled for repair work. |

| Better heat dissipation from windings. | Heat is not easily dissipated from windings since it is surrounded by core. |

| Has longer mean length of core and shorter mean length of coil turn. Hence best suited for EHV (Extra High Voltage) requirements. |

It is not suitable for EHV (Extra High Voltage) requirements. |

Distribution transformer – Design of Transformers

Transformer upto 200kVA (or 500 kVA) are used to step down distribution voltage to a standard service voltage or from transmission voltage to distribution voltage are known as distribution transformers. They are kept in operation all the 24 a hours a day whether they are carrying any load or not.

The load on the distribution transformer varies from time to time and the transformer will be on no-load most of the time. Hence in distribution transformer the copper loss (which depends on load) will be more when compared to core loss (which occurs as long as transformer is in operation). Hence design of transformers are designed with less iron loss and designed to have the maximum efficiency at a load much lesser than full load. Also it should have good regulation to maintain the variation of supply voltage with in limits and so it is designed with small value of leakage reactance.

Power transformer

The transformers used in sub-stations. and generating stations are called power transformers. They have ratings above 200kVA. Usually a substation will have number of transformers working in parallel. During heavy load periods all the transformers are put in operation and during light load periods some transformers are disconnected. Therefore the power transformers should be designed to have maximum efficiency at or near full load. Power transformers are designed to have considerably greater leakage reactance that is permissible in distribution transformers in order to limit the fault current. In the case of power transformers inherent voltage regulation is less important than the current limiting effect of higher leakage reactance.

- See More : Current meter is used to measure

- See More : Tap changing transformer

- See More : Series capacitor voltage