Measurement of roundness is defined as a condition of a surface of revolution. All points of the surface are intersected by any plane perpendicular to a common axis in case of cylinder and come.

Devices Used for Measurement of Roundness

- Diametral gauge.

- Circumferential conferring gauge ⇒ a shaft is confined in a ring gauge and rotated against a set indicator probe.

- Rotating on center

- V-Block

- Three point probe.

- Accurate spindle.

Diametral method

The measuring plungers are located 180° a part and the diameter is measured at several places. This method is suitable only when the specimen is elliptical or has an even number of lobes. Diametral check does not necessarily disclose effective size or roundness. This method is unreliable in determining roundness.

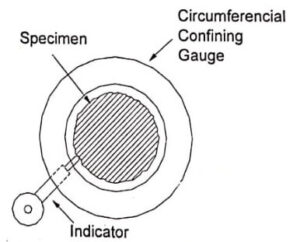

Circumferential confining gauge

Image shows the principle of this method. It is useful for inspection of roundness in large production. This method requires a separate highly accurate master for each size part to be measured. The clearance between part and gauge is critical to reliability. This technique does not allow for the measurement of other related geometric characteristics, such as concentricity, flatness of shoulders etc.

Rotating on centers

Fig shows shaft is inspected for roundness while mounted on center. In this case, reliability is dependent on many factors like angle of centers, alignment of centres, roundness and surface condition of the centres and centre holes and run out of piece.

Out of straightness of the part will cause a doubling run out effect and appear to be roundness error.

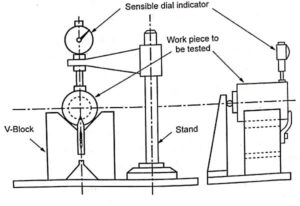

V-Block

The set up employed for assessing the circularity error by using V-Block is shown in image.

The Vee block is placed on a surface plate and the work to be checked is placed upon it. A diameter indicator is fixed in a stand and its feeler is made to rest against the surface of the work. The work is rotated to measure the rise on fall of the work piece.

For determining the number of lobes on the work piece, the work piece is first tested for 60° V-Block and then for 90° V-Block. The number of lobes is then equal to the number of times that the indicator pointer deflects through 360° rotation of the work piece.

Limitations:

- The circularity error is greatly affected by the following factors.

- If the circularity error is Δe, then it is possible that the indicator shows no variation.

- Position of the instrument i.e. whether it is measured from top or bottom.

- Number of lobes on the rotating part.

- The instrument position should be in the same vertical plane as the point of contact of the part is with the V-block.

- A leaf spring should always be kept below the indicator plunger and the surface of the part.

Fixed angle:

Depending on the number of lobes on a part, the following angles of V-block are recommended for the measurement of correct roundness by V-Block method.

| Lobes | Angle of V-block |

| Three point out of roundness | 60° |

| Five lobed part | 108° |

| Seven lobed part | 128°.34′ |

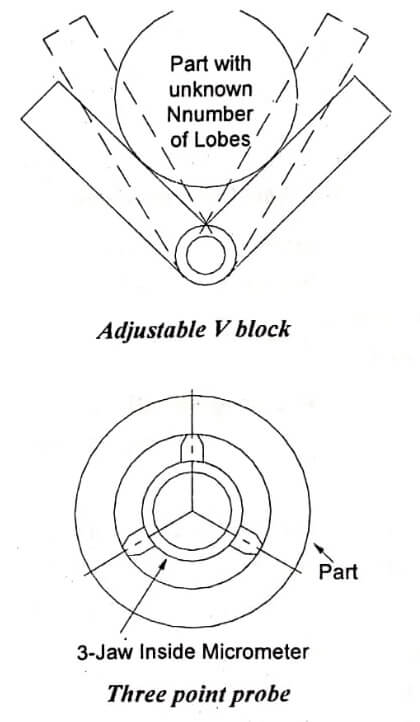

Adjustable V-Block

It is usually difficult to ascertain the number of lobes of a part and have large number of fixed angle V-blocks. V-block which can be adjusted to correct angle to show out of roundness is better choice. The fig shows a adjustable V-block.

Three point probe

The fig shows three probes with 120° spacing is very useful for determining effective size they perform like a 60° V-block.

A 60° V-block will show no error for 5 and 7 lobes magnify the error for 3-lobed parts show partial error for randomly spaced lobes.

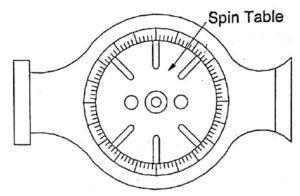

Accurate spindle

Accurate spindle method is a method to provide a definite value for calibration of measurement of roundness when compared to other method. This is suitable for ball bearing, roller bearing etc. It is shown in fig and these spindles are available in a wide range of tolerances.

- See More : Straightness measurement

- See More : Methods of measuring surface finish

- See More : Measurement of screw threads

- See More : Errors in measurement