- Rotational speed of the turbine

- Specific speed

- Maximum efficiency

- Part load efficiency

- Head

- Type of water

- Runaway speed

- Cavitation

- Number of turbine units

- Overall cost.

Rotational speed of the turbine

Turbines are used to produce mechanical energy which is again converted into electrical energy by coupling the generator through the shaft. Here, the speed of the generator is assumed to be the same speed of turbine speed by considering negligible transmission losses. Usually, generators are run at its synchronous speed (Ns).

It is given by the formula

Where, f = frequency

P = Number of pairs of poles.

These generators are always preferred to use high synchronous speed because the number of poles required is less. Thus, the generator size is reduced. Therefore, the constructional cost of the power house is also reduced.

Specific speed

Specific speed is the speed of a geometrically similar turbine, (a turbine identical in shape, dimensions, blade angles and gate openings etc.) which will develop unit power when working under a unit head. The specific speed is used in comparing with the different types of turbines as every type of turbine has different specific speed. In S.I. units, unit power is taken as one kW and unit head as one metre.

Specific speed plays an important role in the selection of a type of turbine. By knowing the specific speed of the turbine, the performance of the turbine can also be predicted. The type of turbine for various specific speeds is given below.

| Specific Speed | Type of turbine |

| 10 to 30 | Pelton turbine with single jet |

| 17 to 50 | Pelton turbine with two jets |

| 24 to 70 | Pelton turbine with four jets |

| 70 to 257 | Francis turbine |

| 257 to 858 | Kaplan turbine |

The following points are worthwhile for noting

- Specific speed is proportional to the speed of rotation. Evidently, the high speed Kaplan turbine is expected to have high specific speed than Pelton wheel.

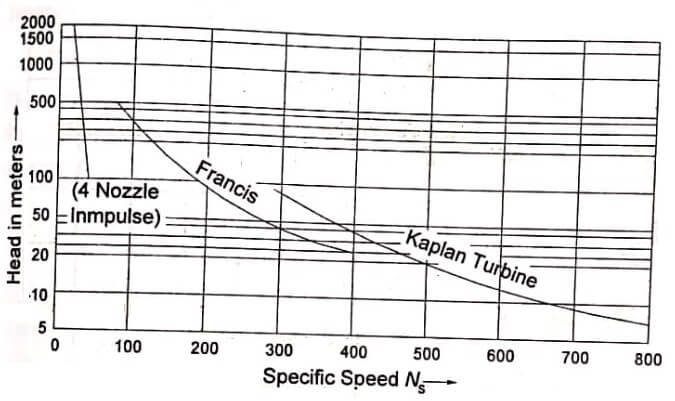

- Specific speed is inversely proportional to head. Obviously, the high head Pelton wheel has a low value of specific speed than Kaplan turbine which operates at low heads.

Specific speed is related with turbine speed. High specific speed is always suggested because the turbine speed will be too low for less head and more power output. It will finally increase the cost of turbo generator thereby increasing the cost of power house installation.

Maximum efficiency

The efficiency of any turbine is calculated based on the power output developed. The turbine which can give maximum power output for the given input will give the maximum efficiency. The maximum output of the turbine depends on the type of turbine used.

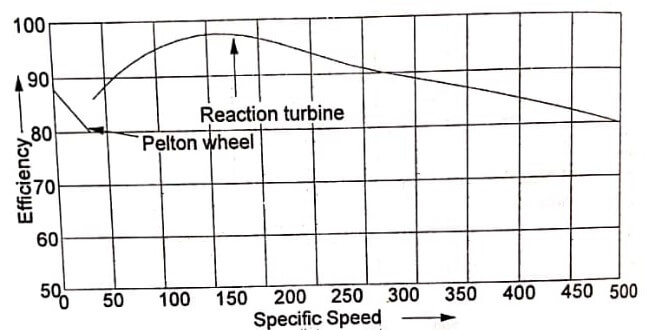

The maximum specific speed of impulse turbine for the highest efficiency is 20 due to low specific speed, large diameter of the wheel which causes more bearing friction and windage losses.

The low specific speed of reaction. turbine causes more friction losses, leakage losses and friction losses. These factors will reduce the efficiency of the turbine by reducing specific speed.

The high specific speed of reaction turbine causes more discharge losses but friction and leakage losses are reduced. Because of more discharge losses, the specific speed of the turbine reduces by pulling down its efficiency. So, these type turbines are suggested to operate medium specific speed and at constant load conditions.

The more efficiency can be achieved by reaction turbine than impulse turbine. The maximum possible efficiency of reaction turbine is 90% but it is 82% for impulse turbine.

At the same time, the Pelton wheel is suggested for smaller powers than reaction turbines, because the efficiency of Pelton wheel is irrespective of its size.

Part load efficiency

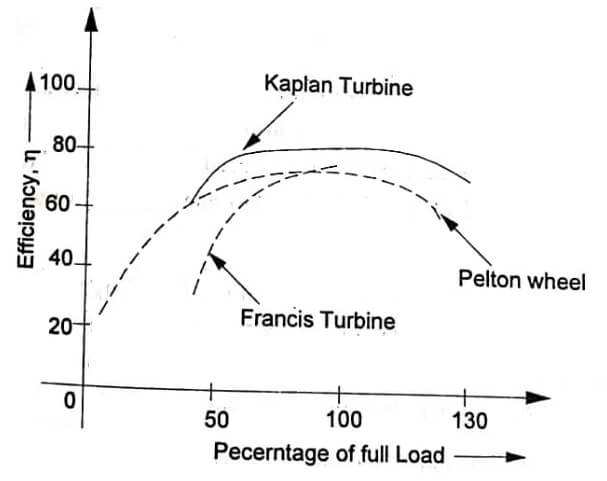

Full load is defined as the load at which the turbine can produce maximum efficiency. If the load increases above the full load, it is known as overload but, if it decreases below the full load, it is known as under load or part load.

The part load efficiency is constant for all types of turbines. It depends on the specific speed and type turbine used.

The flow of water through jet diameter in Pelton turbine is reduced by governing mechanism, when the turbine is operated at part load. So, the absolute velocity at inlet doesn’t change due to this change in flow of water through jet. Therefore, the efficiency curve is more flat.

In reaction turbines, the bucket is completely filled by water. When the turbine is operated at part loads, the absolute velocity changes drastically due to inevitable discharge losses. So, the efficiency is decreased with part load.

The discharge losses are more when the specific speed will be high. Therefore, the Pelton wheel is suggested for high head plants and Francis turbine for low head plants.

At the same time, the efficiency curve remains constant for Kaplan turbine even when the load changes. So, this type of turbine is more suitable for all types of loads even when the load changes from minimum to maximum.

Head

The selection of turbine is a function of speed, power to be developed and head also. These curves are obtained by maintaining a constant head and a constant gate opening as shown in fig. The speed of the turbine is varied by allowing a variable quantity of water to flow through the inlet.

For each speed, the brake power P is measured mechanically by dynamometer and discharge Q is also measured. Then, the. overall efficiency (ηo) for each value of the speed is calculated. From these values, unit speed (Nu), unit power (Pu) and unit discharge (Qu) are calculated.

Taking Nu as abscissa, the values of Qu, Pu and ηo are plotted. The typical main characteristic of the Pelton and Kaplan turbines have depicted in fig. By changing the gate opening, the values Qu, Pu and no and Nu are determined and results are plotted.

Head plays an important role in the selection of the type of turbine. By knowing the head of the turbine, the performance of the turbine can also be predicted. The type of turbine for different head is given below.

Runaway speed

The speed of turbine increases with increase in head. All generators are designed for full runaway speed. At the same time, higher the runaway speed, greater will be the cost of machines. The percentage runaway speed and percentage increase in power versus percentage rated head are shown in fig below.

Type of water available

Reaction turbines are not suitable for dirt and sand water because it will cause erosion of the runner blade. Because of the erosion, more friction losses will be produced. So, purity of water is very important to achieve maximum efficiency. Impulse turbines are more suitable for any kind of water which carries even grit or slit.

Number of turbine units

The efficiency of any turbine depends on the number of units installed. The two similar units will give better average efficiency than the double the size of single unit.

If three or four units are combined, the average efficiency will be still improved than the last one. So, multi-unit plants can meet large variation of load and it will be economic. The running cost and capital

cost expenses will be quiet less for operating the double size of single unit than the two similar units.

Therefore, the selection of turbines based on number of units is a management problem dependent of economic conditions but not a design problem.

Cavitation

Whenever the specific speed of the turbine increases beyond the recommended values, the cavitation might occur. The runner is set at lower elevation from the turbine to avoid cavitiation. If the cavitation is more, runner blades will quickly corrode. To avoid this, dense metal like cast steel and stainless steel can be used rather than porous materials like cast iron.

Mostly, runner is kept below the tailrace to avoid cavitation but it should be in such a way to repair easily when it corrodes.

Overall cost of the plant

All turbines are designed for minimum cost. So, the good design should be in such a way to give maximum efficiency with minimum cost. The total cost includes capital and running costs.

- See More : Balancing of rotating masses

- See More : Optical comparator work