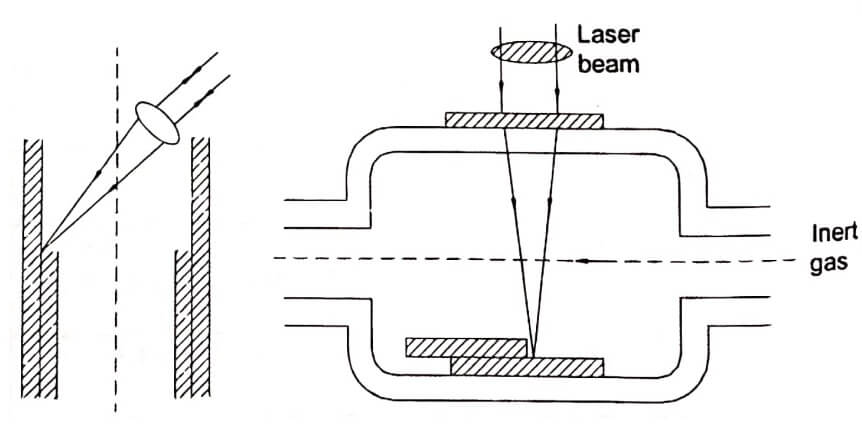

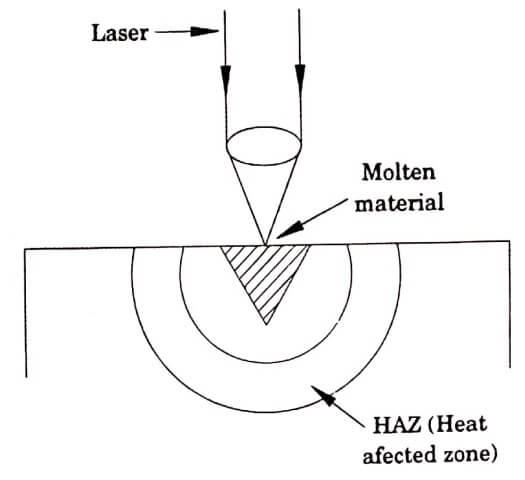

(i) Welding

- Thermal Effect is the basic principle used in laser welding.

- The two ends (A & B) of the specimens are brought together.

- Now, the laser beam is focused for a long time on the ends, that are to be joined.

- Due to thermal effect, portions that are to be welded goes to the molten liquid state.

- At this particular state, atoms in the one end diffuses to the atoms in the other end.

- After that the specimen is allowed to cool slowly.

- Hence, a perfect welding can be obtained.

- Laser welds can easily be performed between two dissimilar metals.

- The Neodymium – YAG laser and Carbon dioxide laser are two important kinds of lasers that find wide ranging applications in welding.

Fig. 1.1 Welding

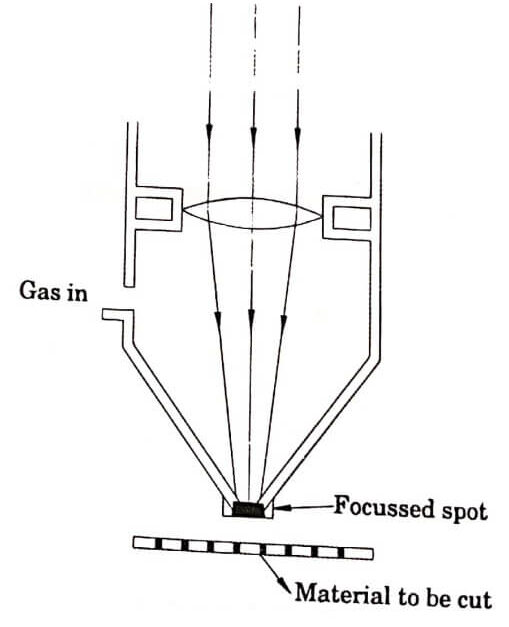

(ii) Cutting

- Thermal effect is the basic principle used in laser cutting.

- The high intensity laser beam is made to fall on the material as shown in figure.

- Due to the application of laser for long time, the temperature of the material is extremely increased. It can hence be used in cutting materials.

- The most common laser that is used in cutting process is the carbon dioxide laser due to its high output power.

Fig. 1.2 Cutting

(iii) Heat treatment

- A powerful laser beam is allowed to hit a metal surface. That portion gets heated.

- As the beam is moved away to other areas, the heated spot cools down rapidly.

- This procedure is used for heat treatment of metal surfaces which enhances the strength of the metal.

- Laser heat treatment provides selective treatment of the desirable areas which are subjected to more intense use.

- For example laser heat treatment is used in automobile industry to strengthen cylinder blocks, valve guides, and gears camshafts etc.

- One kilowatt CO2 laser operating in the continuous wave mode is often used for laser heat treatment.

Fig. 1.3 Laser heat treatment

| Read More Topics |

| Problems for robots in arc welding |

| Welding process gas and arc |

| Medical application of laser |