INTRODUCTION TO WELDING PROCESS

The process of joining similar metals by the application of heat is called ‘welding’. It is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. It is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint.

It can be obtained with or without application of pressure and with or without filler metal. During or addition of welding, the edges of these metal pieces are either melted brought to the plastic condition. The welding process is used for making permanent joints which is obtained by homogenous mixture of two materials. The heat may be developed in several ways for welding operation. A good welded joint is as strong as the parent metal.

Nowadays, welding finds wide spread applications in almost all branches of engineering industries. Welding is extensively employed in the fabrication and erection of steel structure in industry and construction e.g. Structural joints of bridges and buildings, pipelines etc. It is also used in various industries such as aircraft frame works, railway wagons, furniture, automobile bodies, ship building etc. depending upon their applications.

CLASSIFICATION OF WELDING PROCESS BASED ON THE METHOD OF WELDING

In general various welding processes are classified as follows:

1. Gas welding:

(a) Air-acetylene welding

(b) Oxy-acetylene welding

(c) Oxy-hydrogen

2. Arc welding:

(a) Carbon arc

(b) Plasma arc

(c) Shield metal arc

(d) Tungsten Inert Gas (TIG)

(e) Metal Inert Gas (MIG)

(f) Submerged arc

(g) Electro-slag

3. Resistance:

(a) Spot

(b) Seam

(c) Projection

(d) Resistance Butt welding

(e) Flash Butt welding

(f) Percussion

4. Solid state welding:

(a) Cold

(b) Diffusion

(c) Forge welding

(d) Explosive welding

(e) Friction

(f) Ultrasonic

(g) Hot pressure

(h) Roll welding

5. Thermo chemical:

(a) Thermit welding

(b) Atomic

6. Radiant energy:

(a) Electric Beam

(b) Laser Beam

There are two main types of welding process which are classified according to the source of energy employed for heating the metals and the state of metal at the place being welded.

Fusion Welding

In fusion welding, the metal at the joint is heated to a molten state and then it is allowed to solidify. When heat alone is used during welding, the process is called fusion welding. Pressure is not applied during the welding process, and hence, it is also called weld. Filler material may be required during this type of weld. non-pressure

Examples: Gas welding, arc welding, electron beam welding,

In pressure or plastic welding, the metal parts are heated a plastic state and they are pressed together to make the joint. Hence, it is known as pressure welding. Here, there is no filler materials required.

CLASSIFICATION OF WELDING PROCESS BASED ON THE FILLER METALS

Based on the application of filler metals, the welding process can also be classified as follows:

(a) Autogeneous: The process is one in which no filler metal is added to the joint interface.

Example: Electric resistance weld.

(b) Homogeneous: The process is one which the filler metal is added and it is similar to parent metal.

Examples: Arc welding, electron beam welding and diffusion.

(c) Heterogeneous: The process is one which the filler metal is used but it is of different type from the parent metal.

Examples: Brazing and soldering.

GAS WELDING

Gas welding is one type of welding processes In which the edges of the metals to be welded are melted by using a gas flame. No pressure is applied during welding except pressure gas weld. The flame is produced at the tip of a weld torch. The welding heat is obtained by burning a mixture of oxygen and combustible gas. The gases are mixed at the required proportion in a welding torch which provides a control for the welding flame. The gases commonly employed for gas welding are acetylene, hydrogen, propane and butane. The flame only melts the metal. So, filler rod. A flux is the additional metal required to the weld is supplied by the used during welding to prevent oxidation and remove impurities: Metal having 2 mm to 50 mm thick are welded by gas welding. Based on the type and combination of gases used for producing flame, there are three types of gas welding processes used in industries such as

(a) Air-acetylene

(b) Oxy-acetylene

(c) Oxy-hydrogen

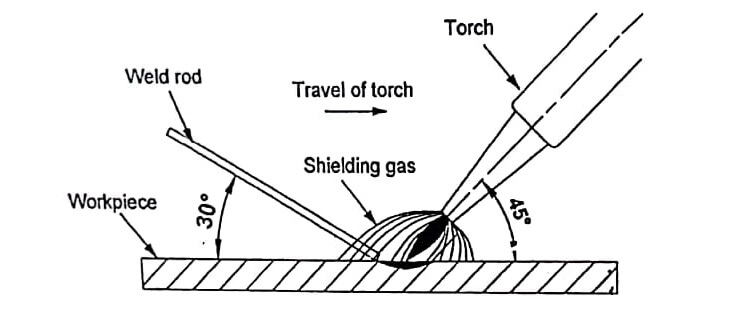

Oxy-Acetylene

The most common form of gas welding is oxy-acetylene weld. It is commonly used to permanently join mild steel. The use of oxygen and acetylene as welding gases dates back to the 1890’s. The combination of oxygen and acetylene produces a flame temperature about 3200°C, making it ideal for welding and-cutting. When the flame comes in contact with steel, it melts the surface forming a molten pool and allowing welding to take place as shown in image. Oxyacetylene can also be used for brazing, bronze welding, forging shaping metal and cutting. This type of welding is suitable for the prefabrication of steel sheet, tubes and plates.

The gases oxygen (O2) and acetylene (C2-H2) can, be stored at high-pressure in separate steel cylinders. But, the acetylene is very harmful if it is not handled carefully. The cost of acetylene is low.

. Air-Acetylene

This process is similar to oxy-acetylene weld process. Here, air is used instead of oxygen. The air taken from the atmosphere is compressed in a compressor and it is mixed with acetylene to the required proportion in the torch. This type of welding has limited use since the temperature is lower than other gas process. It is successfully used in lead weld and many low melting temperature metals and alloy.

Oxy-Hydrogen

This process is similar to oxy-acetylene process. Here, oxygen and hydrogen gases are mixed with the required proportion for producing heat. In this process a special regulator is used for metering the hydrogen gas. It was once used extensively to weld low temperature metals such as aluminum, lead and magnesium but it is not in use today because more versatile and faster welding process has been developed.

Gas Weld Equipment

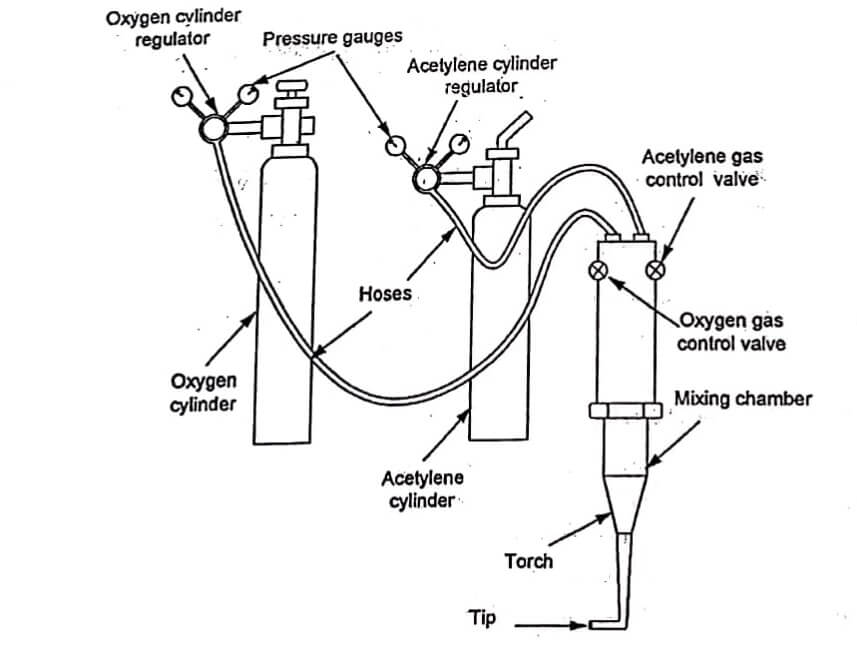

The following are the most commonly used equipment in image for gas weld.

Gas cylinders: For gas weld, a mixture of oxygen and acetylene are used. These two gases are stored in separate cylinders. The standard colour for oxygen cylinder is black. The oxygen is stored in the cylinder, at a pressure of 125 to 140 bar. Its capacity is 6.23 m’. The standard colour for acetylene cylinder is maroon. It is stored at a pressure of 16 bar. Its capacity is 7.6 m.

Acetylene cylinder is fitted with a fusible plug to avoid explosion.

and 2.8 bar. The working pressure of acetylene is between 0.07 bar and 1.03 bar depending upon the thickness of the work pieces to be welded.

Pressure gauges: There are four pressure gauges provided in which two are placed on the oxygen cylinder regulators and two on acetylene cylinder regulators. Among two, one pressure gauge to show the cylinder pressure and the other is used is used to show the working pressure for welding.

Hoses: The regulator should be flexible, of each cylinder is connected to the torch through two long hoses. It strong, desirable, non-process and light. Oxygen cylinder is connected with black colour hose whereas the acetylene cylinder is connected with red colour hose.

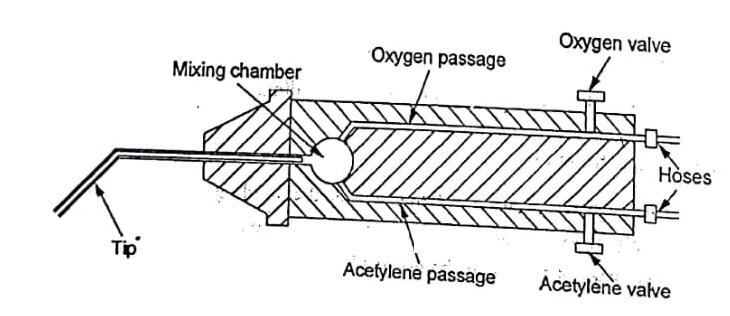

Torch Weld: Oxygen and acetylene gases shown in Figure enter the torch through the hose in separate passages as 1.6. Both gases are mixed in the mixing chamber of the ignited, a flame will be produced at the tip of the torch called a torch. When it is. nozzle. There are two control valves on the weld torch. They are used to control the quantity of oxygen and acetylene to adjust the flame. The nozzles or tips are made of copper or copper alloy. Tips are in different sizes depending upon the type of metal to be welded and its thickness.

There are two types of torches as follows:

(i)Equal pressure type, and

(ii) Injector type.

Check valves or control valves: Check valves are necessary safety devices attached between hoses and regulator outlets. Check valves allow the gases to flow in only one direction to prevent back flow.

Flash back arrestors: Flashback is an explosion occurring at the tip accompanied by gases burning back into hoses and regulator. A flashback can occur if there are no check valves or check valves fail to operate due to improper installation. Once a flashback starts, check valves cannot stop it but a Nashback arrestor will. The arrestor connected to the hose at the torch or regulator, same as the check valves. It contains a trap which is spring loaded that cuts off the gas flow in the event of a flashback.

Goggles: The welding goggles are used to protect eyes from the flame heat, and ultraviolet and infrared rays.

Welding gloves: Gloves are used to protect hand from the injury which may be caused by heat and metal splashes.

Spark lighter: It is an igniter to start the burning of oxy acetylene gases.

Wire brush: It is used to clean the weld joint before and after weld.

Flame Characteristics

It is very important to adjust the flame to suit the weld conditions. It is done by regulating the supply of oxygen and acetylene. By varying the ratio of oxygen and acetylene, the following three types of flames can be obtained.

(i) Neutral flame

(ii) Carburising flame and

(iii) Oxidising flame

(i) Neutral flame.

Neutral flame is obtained by supplying equal quantity of oxygen and acetylene. Neutral flame has two zones i.e. one sharp bright inner cone and one sharp bright inner cone and one bluish outer cone as shown in image.

Filler Rods for Gas Weld

Filler rod used in gas weld is to supply additional metal to make the joint. It is a metal rod which is made of the same material as a parent metal. Diameter of the filler rod depends on the thickness of the metal to be weld. The filler rod diameter ‘d can be approximately determined by the following relationship.

d=t/2+ 1 where t – thickness of the metal to be welded in mm.

Different alloying elements such as chromium and nickel can be added to the filler rod.

It will increase the strength of the joint. Filler rods are coated with oxidation of the molten metal. copper to prevent oxidation of the molten metal.

Advantages, Limitations and Applications of Gas Weld

Advantages:

- Temperature of flame can be easily controlled.

- The amount of filler metal deposits can be

- The flame can be used for weld controlled easily

- and cutting

- The cost of equipment is less.

- It can be used in the factory or in the field.

- Maintenance cost of gas weld equipment is less.

All types of metal can be welded.

Limitations:

It is not suitable for joining thick plates.

It is a slow process.

Strength of weld is not so good as arc weld.

Handling and storing of gas cylinders need more care.

Gas flame takes up a longer time to heat up the metal than an electric arc.

Applications:

- Oxyacetylene weld is used extensively for joining and cutting of thin steel sheets.

- It is also used for weld of dissimilar metals, brazing, braze-weld, silver soldering, metal heating (for bending and forming) and oxy-fuel cutting.

CARBON ARC WELD

In arc weld process, the heat is, developed by an electric arc. The arc is produced between an electrode and. the work. An arc is a sustained electric discharge through the ionized gas column called plasma between two electrodes. In order to produce the arc, the potential difference between two electrodes should be sufficient to allow them to move across the air gap. The larger air gap requires, higher will be potential differences. If the air becomes too large for the voltage, the arc may be extinguished.

The arc formation is similar for both AC welding or DC weld. In AC, the polarity changes continuously and hence, the polarity is fixed and temperature across the arc is uniform. In DC, the hence, the heat is more concentrated at one of the electrodes. Heat is produced by the electric arc to fusion weld metallic pieces. Electrons liberated from the cathode move. towards the anode and they are accelerated in their movement. When they strike the anode at high velocity, large amount of heat is generated. Electrons are moving through the air gap between electrodes also called arc column. They collide with the ions in the ionized gas column between electrodes.

Arc weld is the process of joining two metal pieces by melting their edges by an electric arc. In arc weld, the electrical energy is converted into heat energy.