Detonation in S.I Engines: If the temperature of an air fuel mixture is raised high enough, the mixture will self ignite without the need of a spark plug Knocking or detonation in S.I engines. This phenomenon is called as self ignition or Auto ignition. The temperature above which self ignition occurs called the self ignition temperature.

If the temperature of the unburnt mixture exceeds the self ignition temperature during the ignition delay period, auto ignition occurs at various locations in the cylinder. This will generate pressure pulses. These high pressure pulses can cause damage to the engine and quite often are in the audible frequency range. This phenomenon is often called knocking or detonation.

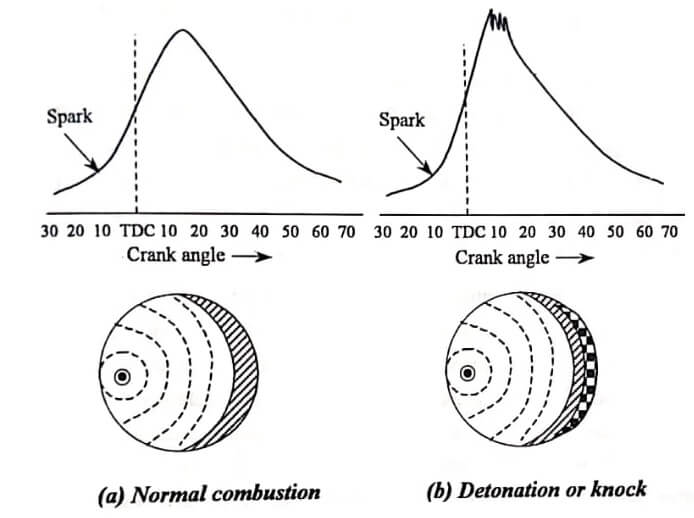

Fig. (a) and (b) show the normal combustion and knocking or detonation combustion in S.I engine respectively. In normal combustion (Refer fig. (a)), a normal flame front travels across the combustion chamber from A towards D. The advancing flame front compresses the unburned charge BB’D, thus raising its temperature. The temperature is also increased by radiation from the hot advancing flame-front. If this unburnt change does not reach its self-ignition temperature, it will not auto-ignite and the flame front BB’ will move further and consume the charge BB’D. The P = Q diagram for normal combustion is a smooth curve.

In the abnormal combustion called knocking or detonation, the end charge auto ignites before the flame front reaches it. As shown in fig. (b) when the flame has reached the position BB’, the charge ahead of it has reached self-ignition temperature. During the ignition delay period if the flame front could move from BB’ to only CC’ then the unburnt charge ahead of CC’ would auto ignite. This auto ignition results in traveling of another flame front in the opposite direction to the main flame front. When two flame front collide, a server pressure pulse is generated. This pressure wave strikes the cylinder wall and set it vibrating, giving rise to a high pitched metallic ‘pinking’ or ringing sound. This phenomenon is therefore known as ‘knocking’.

Knocking in S.I engine always occurs near the cad of combustion whereas in C.I engine it occurs in the beginning of combustion. The term detonation is used to indicate specifically the presence of pressure wave and therefore, the presence of gas vibration. The term knock is used to include all phenomena that arise from auto-ignition. Detonation in S.I engines can be suppressed by addition of only a small quantity (1/900 Volume) of tetraethyl lead. This process is called ‘Doping’.

Effect of knocking

- The impact on the engine components and structures may cause failure and creates undesirable noise which is always objectionable.

- The lack of control of combustion process leads to pre ignition and local over-heating. Therefore, piston may be damaged by overheating.

- The pressure differences in the combustion chamber cause the gas to vibrate and scrub the chamber walls causing increased loss of heat to the coolant.

- Detonation results in increased carbon deposits on the wall of the cylinder.

- Due to increase in the rate of heat transfer, the power output as well as efficiency of the engine will decrease.

Factors affecting Detonation in S.I engines

The various engine variables affecting detonation can be classified under four factors, namely, the temperature factors, density factors, time factors and composition factors.

Temperature factors

Increasing the temperature of the unburnt mixture by any factor in design or operation will increase the possibility of knock in the S.I engine. The temperature of the unburnt mixture is increased by the following factors:

- Raising the compression ratio.

- Supercharging.

- Raising the inlet air temperature.

- Raising the coolant temperature.

- Increasing the load.

- Raising the temperature of the cylinder and combustion chamber walls.

- Advancing the spark timing.

Density factors

Any factors which increase the density of the charge tend to increase in knocking by providing excess energy release. The following method will increase the possibility of knock in the S.I engine.

- Increasing the compression ratio.

- Opening the throttle.

- Supercharging the engine.

- Increasing the inlet pressure.

- Advancing the spark timing.

Time factors

Increasing the flame speed or reducing the duration of the ignition delay period or reducing the time of exposure of the unburnt mixture to auto ignition condition it will tend to reduce knocking. The following factors will increase the possibility of knocking:

- Increasing flame travel distance: Engine size, combustion chamber size and spark plug position are the three factors governing the flame travel distance.

- Decreasing the turbulence of mixture.

- Decreasing the speed of the engine.

- Increasing the time available for preflame reaction.

Composition factors

The properties of fuel and the fuel-air ratio are the primary means for controlling knock, once the compression ratio and engine dimensions are selected. The probability of knock is increased by the following factors:

- Low octane number

- Lean mixture of air fuel ratio

- Decreasing atmospheric humidity

- Low self ignition temperature

- Short ignition delay

Is knocking and detonation the same in an engine?

No, knocking and detonation are not the same, but they are related. Knocking occurs when the air-fuel mixture in an engine’s cylinder ignites prematurely, causing a pinging noise and reducing efficiency. Detonation is a more severe form of knocking, where the fuel-air mixture explodes violently instead of burning smoothly, leading to engine damage. Both affect performance, but detonation is more destructive and must be prevented with proper fuel quality and ignition timing.

What is detonation and knocking in an engine?

Detonation and knocking are abnormal combustion phenomena in internal combustion engines. Knocking occurs when the air-fuel mixture ignites prematurely, creating a metallic pinging sound and reducing engine efficiency. Detonation is a more intense and uncontrolled explosion of the fuel mixture, leading to high pressure and potential engine damage. Both can be prevented by using high-octane fuel, proper ignition timing, and maintaining optimal engine conditions.

Read also: Comparison of knock in SI and CI engines