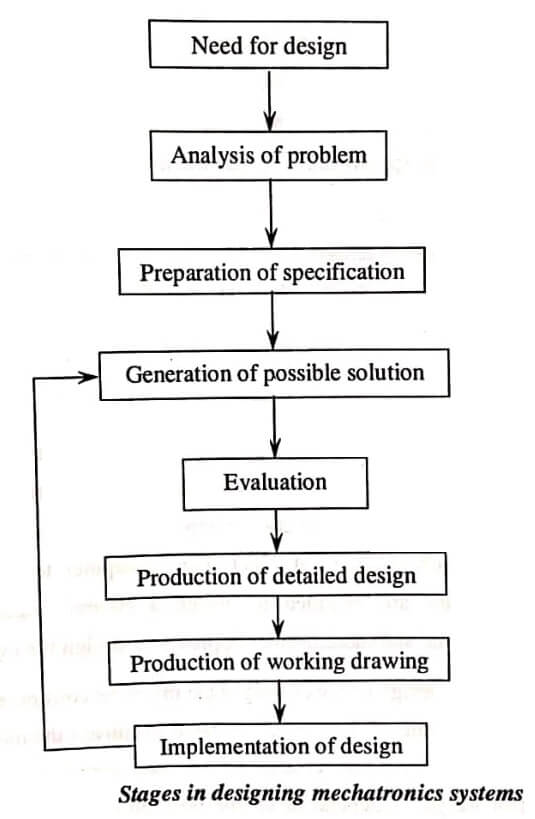

The mechatronics system design process consists of the following stages.

Stage 1: Need for design

The mechatronics system design process begins with a need. Needs are usually arise from dissatisfaction with an existing situation. Needs may come from inputs of operating or service personal or from a customer through sales or marketing representatives. They may be to reduce cost, increase reliability or performance or just change because of public has become bored with the product.

Stage 2: Analysis of problem

Probably the most critical step in a mechatronics system design process is the analysis of the problem i.e., to find out the true nature of the problem. The true problem is not always what it seems to be at the first glance. Its importance is often overlooked because this stage requires such a small part of the total time to create the final design. It is advantageous to define the problem as broadly as possible. If the problem is not accurately defined, it will lead to a waste of time on designs and will not fulfill the need.

Stage 3: Preparation of specification

The design must meet the required performance specifications. Therefore, specification of the requirements needs to be prepared first. This will state the problem definition of special technical terms, any constraints placed on the solution,

and the criteria that will be used to evaluate the design. Problem statement includes all the functions required of the design, together with any desirable features. The following are some of the statements about the problem:

- Mass and dimensions of design.

- Type and range of motion required.

- Accuracy of the element.

- Input and output requirements of elements.

- Power requirements.

- Operating environment.

- Interfaces.

- Relevant standards and code of practice

Stage 4: Generation of possible solution

This stage is often known as conceptualisation stage. The conceptulisation step is to determine the elements, mechanisms, materials, process of configuration that in some combination or other result in a design that satisfies the need. This is the key step for employing inventiveness and creativity.

A vital aspect of this step is synthesis. Synthesis is the process of taking elements of the concept and arranging them in the proper order, sized and dimensioned in the proper way.

Outline solutions are prepared for various possible models which are worked out in sufficient details to indicate the means of obtaining each of the required functions.

Stage 5: Selection of suitable solution or Evaluation

This stage involves a involves a thorough analysis of the design. The evaluation stage detailed calculation, often computer calculation of the performance of the design by using an analytical model. The various solutions obtained in stage 4 are analysed and the most suitable one is selected.

Stage 6: Production of detailed design

The detail of selected design has to be worked out. It might have required the extensive simulated service testing of an experimental model or a full size prototype in order to determine the optimum details of design.

Stage 7: Production of working drawing

The finalised drawing must be properly communicated to the person who is going to manufacture. The communication may be oral presentation or a design report. Detailed engineering drawings of each components and the assembly of the machine with complete specification for the manufacturing process are written in the design report.

Stage 8: Implementation of design

The components as per the drawings are manufactured and assembled as a whole system.

| Read More Topics |

| Control system in mechatronics |

| Traditional and mechatronics design |

| Mechatronic engineering |