Press is a metal forming machine tool used to shape or cut metal by applying force. Press working may be defined as a chipless manufacturing process by which various components are made from sheet metal. Many components in our day to day life are made by press working operations. Press working is mainly useful for mass production work.

They are the fastest and most efficient method to form a sheet metal to. the desired shape. They have got very wide applications, such as electronic appliances, steel furniture, coach building, automobile industry, utensils, two wheeler industry, aircraft industry, ship building industry.

Press Working

There are three different ways of working sheet metal in the press:

Shearing: In shearing operations, a sheet metal is deformed to a shear failure in order to cut various contours from the metallic sheet.

Bending: It is a localised deformation within the plastic range.

Drawing: In drawing operations, there is a deformation within plastic range involving a considerable change of shape.

Advantages of press working

The following are the advantages of press working:

- Material economy

- Reduction of weight and considerable cost reduction of fabricated parts

- High productivity

- Use of unskilled labour

- High degree of precision

- Uniformity of parts

- Predictable strength characteristics

- Use of less labour

- Possibility of automation.

Applications of press working operations

- Electronic appliances

- Steel furniture

- Coach building

- Automobile industry

- Utensils

- Two wheeler industry

- Aircraft industry and

- Ship building industry.

Press Working Terminology

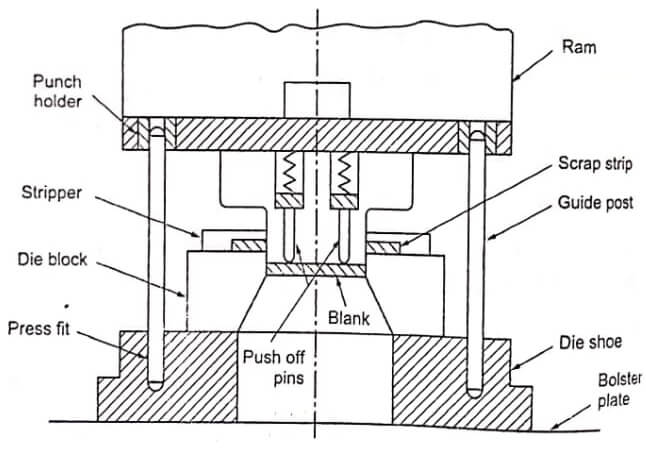

The complete die set used for punching and blanking operations is shown in Figure. The various accessories are provided in the die set for ensuring a proper alignment of punch and die to guide the moving parts. The definitions of the main components are given below:

Base: It is the lower part of the press frame on which all parts of the die set are mounted.

Bolster plate: The bolster plate is the thick plate mounted on the base. It is used for locating and supporting the die assembly. It is usually 5 to 12.5mm thick plate.

Die: It is the female part of the die set. Die has an opening to receive the punch. It is made of a hard, wear resistant metal and, precision ground to size. A proper clearance is provided in the die for blanking and piercing operations. Die is usually held in the die holder or die shoe with some location elements.

Stripper: Strippers are used to prevent the metal strip from coming up along with the punch when it returns back after punching. It may also guide the sheet.

Punch: It is the male member of the die set which forces the sheet metal strip down against the die and may pierce it or draw it. It is made with sufficient strong and rigid from a hard and wear resistant material and accuracy finished to provide just the required clearance between Punch and die.

Punch Plate: it is used to hold the punch in a proper alignment with the die and is secured to the punch holder.

Punch holder or Upper shoe: It is also known as punch retainer. It is directly fastened to the ram of the punch press and holds the punch plate below it.

Backup plate: It is a hardened steel plate incorporated between the punch top and punch holder. It is used to distribute the pressure evenly over a wide area and prevent the concentration of the pressure on the punch holder. It is also known as backing plate.

Guide post or guide pin: The guide post provides alignment between die shoe and punch holder. The guide bushings are mounted in the punch holder and slide over the guide post.

Pitman: It is a connecting rod which is used to transmit motion from the main drive shaft to the press slide.

Shut height: It is the distance from the top of the bed to the bottom of the slide with the stroke down and the adjustment up.

Stroke: The stroke of a press is the distance between two extreme points of motion of the ram. It is equal to twice the crankshaft throw. The stroke is constant for mechanical drive but, it is variable for hydraulic drive press.

Working Principle of a Die Set

A die set consists of three components viz., punch holder, die shoe and guide posts. The punch holder is fastened to the ram of the press and the die shoe is fastened to the bolster plate of the press.

The guide posts are used to align the punch holder better with the die shoe. The lower end of the guide posts is press fitted into the die shoe. The upper end has a slip fit with the guide bushings of the press holder. The punch and die block are fastened to the punch holder and die-shoe respectively.

When the punch moves into the die block, cutting action takes place. Due to elastic recovery (spring back), the size of the blank increases and that of hole in the strip decreases. This results the clogging of blank in the die opening and clinging of strip to the punch. To avoid clinging action, a stripper plate is used.

The walls of the die-opening are tapered to avoid clogging of blank in the die opening. Sometimes, the blank may also adhere to the face of the punch. To avoid this, push-off pins are provided, as shown in Figure.

Press Work Operations

The broad classification of sheet metal operations are under the following two categories:

(i) Cutting operations

(ii) Forming operations

In cutting operations, the workpiece is stressed beyond its ultimate strength and cut-off into two pieces. In forming operations, the stresses are below the ultimate strength of the metal. There is no cutting-off metal but the contour of the workpiece is only changed to get the desired product.

The common cutting operations are discussed below.

Blanking: Blanking is the operation of cutting a flat shape from sheet metal. The metal that is punched out is called a ‘blank’ and the metal that is left out is called scrap.

Punching or Piercing: It is the operation of producing the hole on the workpiece by a punch. In punching, the metal removed is the scrap, and the metal that is left out is called workpiece.

Parting: It is the operation through which the metal is cut simultaneously along two parallel lines or contours or any other two lines which can balance each other to neutralise the side thrust.

Notching: It is the operation through which metal pieces are cut from the edge of a sheet, strip or blank.

Trimming: It is the operation used for removing excess metal, irregular outlines and waved edges, etc., from the walls of drawn shells or the surfaces of swaged and cast parts.

Shaving: It is also similar to trimming operation but here the amount of metal removal is usually about 10% of the thickness of the blank.

Perforating: In this operation, multiple holes which are very small and close together are cut into flat work material.

Slitting: It is the operation of making an unfinished cut through a limited length only.

Lancing: Lancing consists of cutting the sheet metal through a small length and bending this small cut portion downwards.

- See More : Mechanical comparators advantages

- See More : Underfeed stoker classification

- See More : Balancing of rotating masses