There are several forms of braking applicable to the usual types of electric motors. Generally, we can group all electrical braking methods into three types.

- Regenerative braking

- Dynamic or Rheostatic braking

- Plugging or reverse current braking

Regenerative braking

In the regenerative braking operation, the motor operates as a generator, while it is still connected to the supply. Here, the motor speed is greater than the synchronous speed.

Mechanical energy is converted into electrical energy, part of which is returned to the supply and rest of the energy is last a neat in the winding and bearings of the electrical machine. Most of the electrical machines pass smoothly from motoring region to generating region, when over driven by the load.

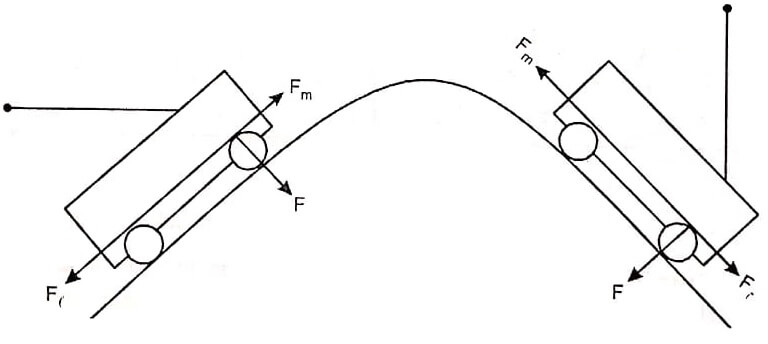

An example of regenerative braking as shown in figure (a). Here an electric motor is driving a trolley bus in the uphill and downhill direction. The gravity force can be resolved into two components in the uphill direction. One is perpendicular to the load surface F and another one is parallel to the road surface Fl The parallel force pulls the motor toward the bottom of the hill.

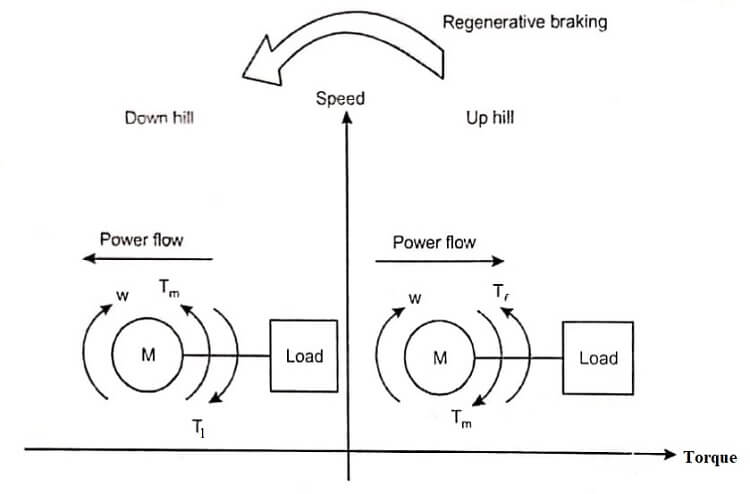

If we neglect the rotational losses, the motor must produce a force Fm opposite to Fl to move the bus in the uphill direction. This operation is indicated as shown in figure in the first quadrant. Here, the motor torque and speed are in the same direction but the load torque Tl is opposite to the motor torque Tm. The power flow is from the motor to the mechanical load.

Now we consider that the same bus is traveling downhill. The gravitational force does not change its direction but the load torque pushes the motor toward the bottom of the hill. The motor produces a torque in the reverse direction because of the direction of the motor torque is always opposite to the direction of the load torque.

Here, the rotation of the motor is still in the same direction on both sides of the hill. This operation is indicated in figure in the second quadrant. This is known as regenerative braking.

In this regenerative braking mode, the motor torque and speed are in the opposite direction. The load torque Tl is opposite to the motor torque Fm. The energy is exchange under regenerative braking operation is power flows from mechanical load to source. Hence, the load is driving the machine and the machine is generating electric power that is returned to the supply.

Dynamic or Rheostatic braking

When an electric motor rotates, a kinetic energy is stored in its rotating mass. If the motor is disconnected from the supply it continues to rotate for a period of time until the kinetic energy is totally dissipated in the form of rotational losses. The faster the dissipation of the kinetic energy, the move rapid is the braking.

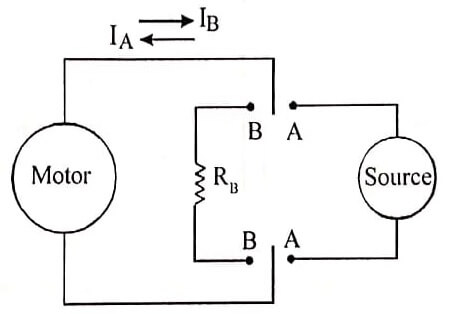

During the dynamic braking the kinetic energy of the motor is converted into electrical energy. This energy is dissipated in resistive elements. The rate of dissipation can be increased by the design of the braking resistance RB. A circuit for rheostatic braking is shown in figure. When the machine is connected to terminal A, it runs as a motor. While the motor is rotating, a kinetic energy is stored in its rotating mass.

The current in flows into the machine is power flows from source i.e. power flows from source to motor. If the terminals of the motor is disconnected from the source and connected to the position B i.e., the breking resistance RB is connected across the motor terminals.

The energy stored in the rotating mass is dissipated in the braking resistance RB. This is possible when the machine maintains its field. The braking current IB flows from motor to braking resistance. If we are using smaller resistor, the energy dissipated is faster and the motor brakes also faster.

When the machine is operating as a rheostatic braking mode, it acts as a generator. The speed of the machine does not change its direction of rotation during braking mode. The machine torque also changes due to reverse current (IB is opposite to IA).

Plugging

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”What is meant by plugging?” img_alt=”” css_class=””] The plugging operation can be obtained by changing the polarity of the motor. For a machines, the phase sequence of the starter winding and dc machines the polarities of the field or armature terminals. [/sc_fs_faq]

The direction of rotation of an electric motor is dependent on several variables. For ac machines, the phase sequence of the stator windings are one of the variable and dc machines, the polarities of the field or armature voltage.

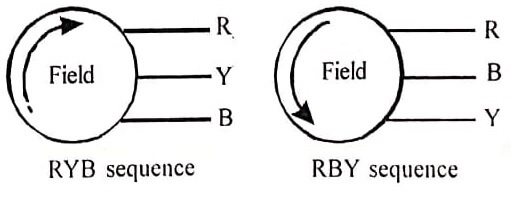

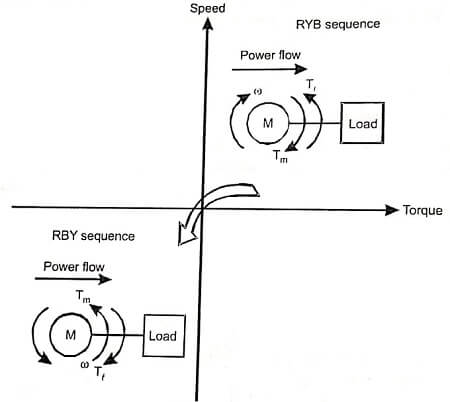

For ac machines, the shaft of the machine rotates in the same direction, as the magnetic field. If the phase sequence of the stator windings is reversed (RBY), the airgap field also reverses its direction, as shown in figure.

By interchanging any two supply terminals, the braking torque is produced, so that the direction of rotation of the rotating magnetic field is reversed with respect to the rotation of the motor. The electromagnetic torque developed provides the braking actions and brings the rotor to a quick stop. Figure shows two quadrants for the steady – state operation of two – sequences (RYB and RBY). In each case, the machine is running as a motor. This type of braking is also known as current braking or reverse current braking.

For dc machines, the armature terminals are reversed while running. The supply voltage Ia and the induced emf E act in the same direction. The armature current is reversed, thereby producing a braking torque. The field current is positive.

| Read More Topics |

| Centrifugal governors |

| Speed control of DC Shunt motor |

| Electrical and Mechanical braking |