Have you ever wondered how pipelines, ships, or even underground tanks stay corrosion-free for years? The answer lies in something called a Cathodic Protection System. This technique plays a vital role in preventing corrosion in metal surfaces, which can otherwise lead to significant damage and high repair costs. But what if we could take this a step further? Enter the Cathodic IPS System, a revolutionary integration that combines the benefits of Cathodic Protection with advanced monitoring and control systems to offer optimal protection. Let’s dive deeper to understand what a Cathodic IPS System is and why it is so important.

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”What is an IPS System?” img_alt=”” css_class=””] To understand a Cathodic IPS System, we first need to know what an IPS System is. IPS stands for Intelligent Protection System. An IPS is designed to offer real-time monitoring and automated control over protective systems. These systems are commonly used in industries to enhance the efficiency, safety, and lifespan of various infrastructure elements. [/sc_fs_faq]

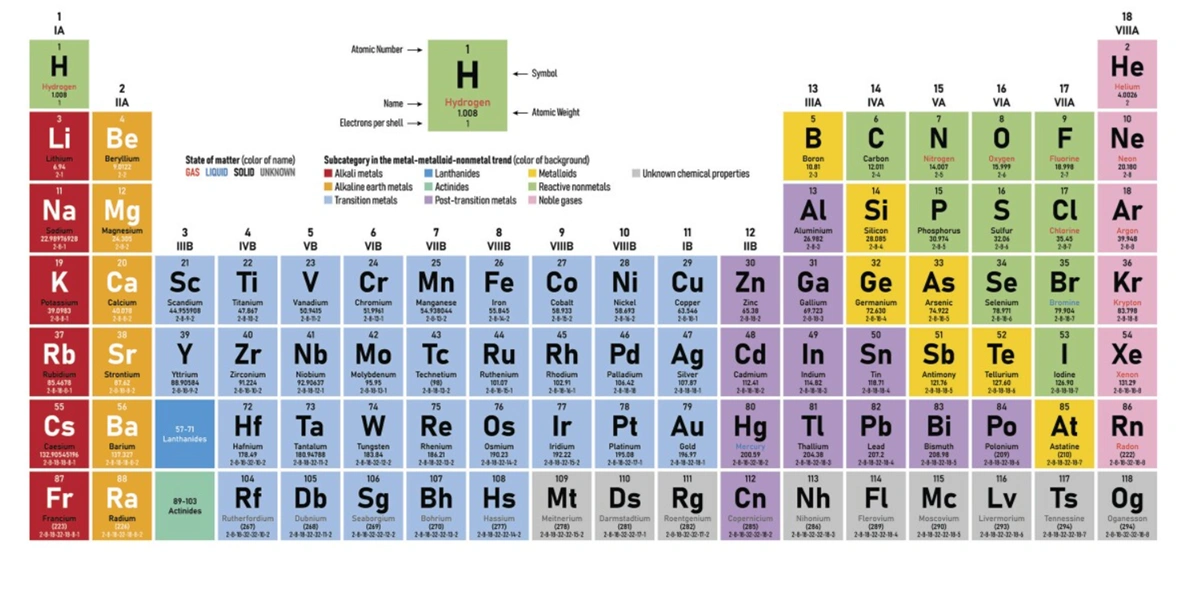

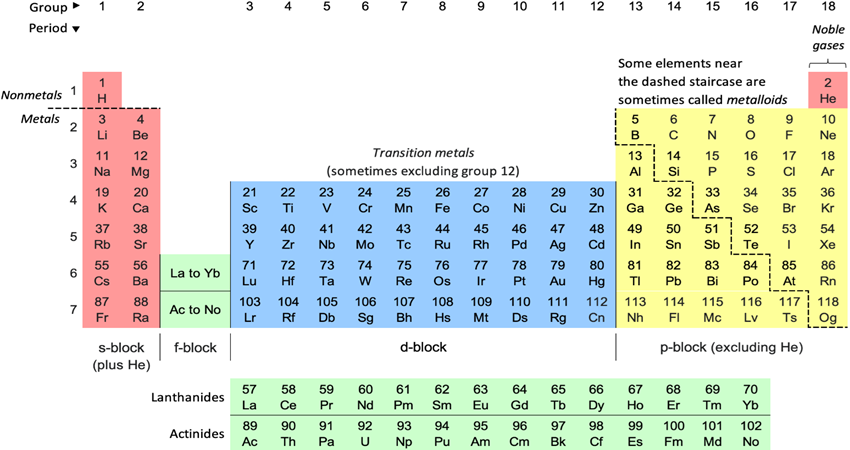

Cathodic Protection is a well-established method used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. This technique involves electrochemical reactions that help in preventing rust and deterioration of metal structures. It is most commonly applied to pipelines, storage tanks, and offshore structures, among others.

What is a Cathodic IPS System?

So, what happens when you combine Cathodic Protection with an Intelligent Protection System (IPS)? You get a Cathodic IPS System! This integrated system not only protects metal structures from corrosion but also incorporates smart technologies that allow for real-time adjustments, efficient monitoring, and proactive maintenance. Essentially, it’s Cathodic Protection on steroids.

Components of a Cathodic IPS System

A Cathodic IPS System consists of several critical components:

- Power Supply Unit: Provides the necessary electrical energy to the system.

- Control Systems: These are often computer-based and allow for real-time monitoring and adjustments.

- Anodes and Electrodes: Key elements that help in creating the electrochemical reaction required for cathodic protection.

How Does a Cathodic IPS System Work?

A Cathodic IPS System works by continuously monitoring the environment and the state of the metal structure it is protecting. It uses anodes and electrodes to create an electrochemical reaction that prevents corrosion. The intelligent control system then makes real-time adjustments based on environmental conditions, such as changes in moisture levels or temperature, to ensure optimal protection.

Types of Cathodic IPS Systems

There are mainly two types of Cathodic IPS Systems:

- Galvanic Cathodic IPS Systems: These use sacrificial anodes made of a more “active” metal to protect the main metal structure.

- Impressed Current Cathodic IPS Systems (ICCP): These use an external power source to provide the necessary current for protection, making them suitable for larger structures or areas with high corrosion potential.

Design Considerations for Cathodic IPS Systems

When designing a Cathodic IPS Systems, several factors need to be considered:

- Material Selection: Choosing the right materials for anodes and electrodes is crucial.

- Environmental Factors: Factors like soil resistivity, humidity, and salinity play a significant role in system design.

Installation Process of a Cathodic IPS System

Installing a Cathodic IPS System requires a meticulous approach:

- Pre-Installation Survey: Assess the environment and the structure’s condition.

- Installation Steps: Positioning anodes, connecting power supply units, and setting up control systems.

Maintenance and Monitoring of Cathodic IPS Systems

Routine checks and continuous monitoring are essential for maintaining the effectiveness of a Cathodic IPS Systems. Many modern systems now incorporate Remote Monitoring Technologies, which can alert operators to any changes in real-time, allowing for quick adjustments.

Benefits of Using Cathodic IPS Systems

The benefits are immense:

- Longevity of Infrastructure: Extends the life of metal structures significantly.

- Cost Savings Over Time: Reduces the need for frequent repairs and replacements.

Challenges Faced in Cathodic IPS Systems

Despite the benefits, there are challenges:

- Corrosion Under Protection (CUP): Situations where corrosion occurs even under supposed protection.

- System Failures and Mitigation: Understanding and addressing potential failure points in the system.

Latest Innovations in Cathodic IPS Technology

The field is rapidly evolving with new innovations like Smart Cathodic Protection Systems that integrate with IoT devices for even better monitoring and control.

Industries Benefiting from Cathodic IPS Systems

Several industries, including the Oil and Gas Industry and the Maritime Sector, benefit significantly from Cathodic IPS Systems, ensuring the safety and longevity of their critical infrastructure.

what is Cathodic Protection

Cathodic protection is a method used to prevent metal surfaces, like pipelines or ship hulls, from rusting or corroding. It works by connecting the metal to a “sacrificial” metal that corrodes instead, protecting the original metal surface from damage.

| Read More Topics |

| What are the requirements of metallurgical coke? |

| Give a brief account of different kinds of glass |

| Describe the manufacture of Portland cement |