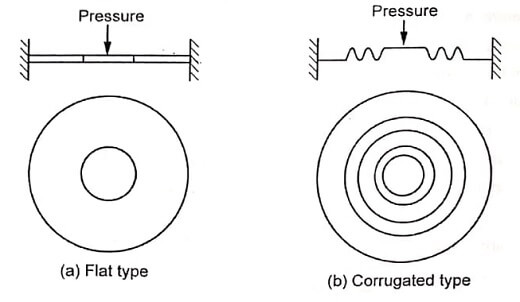

The diaphragm pressure sensor uses the elastic deformation of a diaphragm (i.e. membrane) to measure the difference between an unknown pressure and a reference pressure. Diaphragm is a thin circular elastic membrane made of generally silicon as show in fig. As pressure changed, the diaphragm moves, and. this motion is the measure of differential pressure. Diaphragms are popular because they require less space and the motion they produce is sufficient for operating electronic transducers. They also are available in a wide range of materials for corrosive service applications.

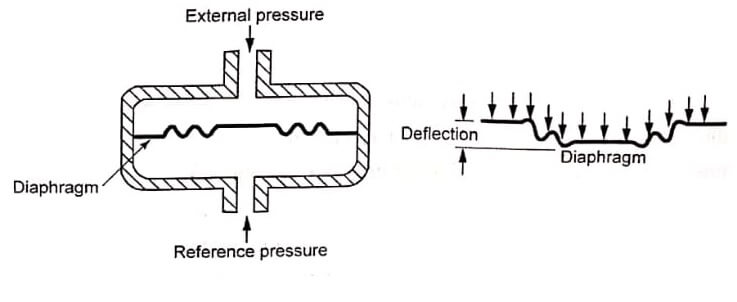

A typical diaphragm pressure gauge contains a chamber divided by a diaphragm, as shown in the fig. One side of the diaphragm is open to the external targeted pressure, PExt, and the other side is connected to a known pressure, PRef,. The pressure difference, PExt – PRef, mechanically deflects the diaphragm.

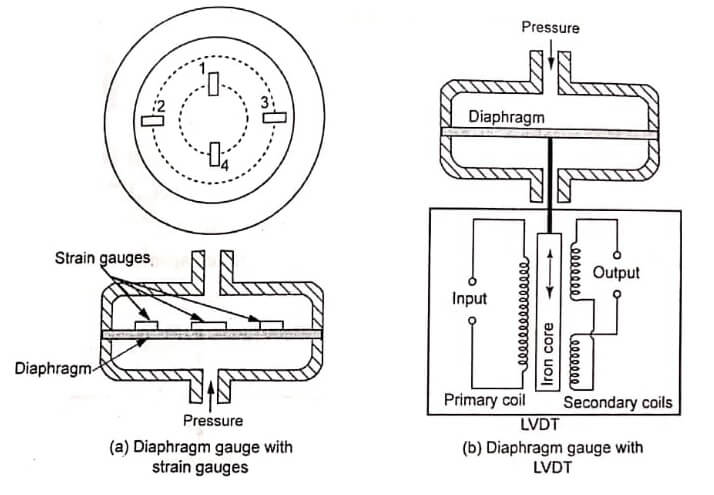

The diaphragm pressure sensor deflection can be measured in any number of ways. For example, it can be detected via a mechanically coupled indicating needle, an attached strain gauge [refer fig (a)], a linear variable differential transformer (LVDT) [refer fig (b)], or with many other displacement/velocity sensors. Once known, the deflection can be converted to a pressure loading using plate theory.

Strain gauge arrangement consists of four strain gauges with, two measuring the strain in a circumferential direction while the remaining two measure strains in a radial direction. The four strain gauges are connected to form the arms of a Wheatstone bridge. The sensitivity of pressure gauges using LVDTs is good and, therefore, stiff primary sensors with very little movement can be used to reduce environmental effects. Frequency response is also good.

Advantages:

✔ Much faster frequency response than U tubes.

✔ Accuracy up to ±0.5% of full scale.

✔ Good linearity when the deflection is no larger than the order of the diaphragm thickness.

Disadvantages:

✔ More expensive than other pressure sensors.

| Read More Topics |

| Strain gauge load cell |

| Definition of metrology liner and angular |

| Mechanical comparator |

| Torque measurement using strain gauge |