Construction Details

A transformer is a static device and its construction is simple as there are no moving parts. The main components of a transformer are

- The magnetic core.

- Primary and secondary windings.

- Insulation of windings.

- Expansion tank or conservator.

- Lead and tappings for coils with their supports, terminals and terminal insulators.

- Tank, oil, cooling arrangement, temperature gauge, oil gauge.

- Buchholz relay.

- Silica gel breather.

Magnetic Core

Magnetic circuit consists of an iron core. ‘The’ transformer core is generally laminated and is made out of a good magnetic material like silicon steel. The thickness of laminations or stampings varies from 0.35mm to 0.5mm. The laminations are insulated from each other by coating then with a thin coat of varnish.

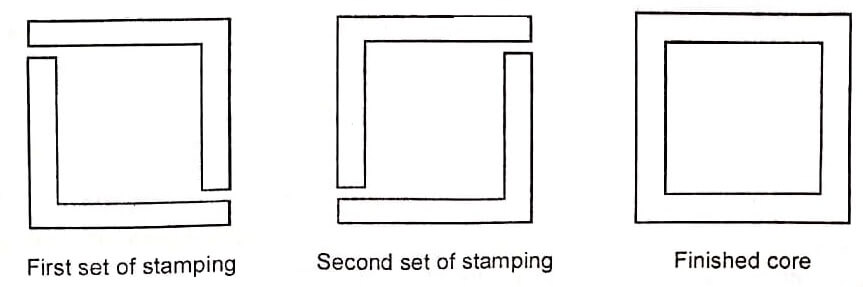

Various types of samplings and laminations employed in the construction of transformers are shown in figure. The joints are staggered to avoid continuous gap causing increase in magnetising current. If the joints are not staggered, the core will have less mechanical strength and during operation there would be undue humming noise. After arranging the laminations they are bolted together.

The two types of transformer cores are:

- Core type

- Shell type

Core type transformer

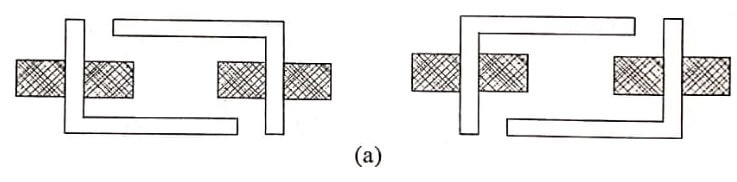

Here the windings surround a considerable part of core as shown in figure and has only one magnetic path. It has two limbs for the two windings and is made up of two L-type stampings as shown in figure (a). The coils used usually are of cylindrical type and are usually wound. For transformers of higher rating stepped core with circular cylindrical coils are used. For transformers of smaller rating, rectangular coils with core of square or rectangular cross section is used. Insulating cylinders are used to separate windings from the core and from each other.

Shell type transformer

Here the core surrounds the considerable part of windings as shown in figure (b). The two windings are carried by central limb. The core is made up of E and I stampings (figure (b) and has three limbs. It has two parallel paths for magnetic flux.

The coils used are of multilayer disc type and are former wound in the form of pancakes. Each layer is insulated from each other by paper.

Winding

There are two windings in a transformer. They are called primary and secondary windings. Generally the windings are made of copper.

Insulation

Paper is still used as the basic conductor insulation. Enamel insulation is used ads the inter-turn insulation for low voltage transformers. For power transformers enamelled copper with paper insulation is also used.

Insulating Oil

The oil used in transformer protects the paper from dirt and moisture and removes the heat produced in the core and coils. It also acts as insulating ‘medium. The oil must possess the following properties

- High dielectric strength.

- Free from inorganic acid, alkali and corrosive sulphur to prevent injury to the conductor or insulation.

- Low viscosity to provide good heat transfer.

- Free from sludging under normal operating conditions,

- Good resistance to emulsion so that the oil may throw down any moisture entering the tank instead of holding it in suspense.

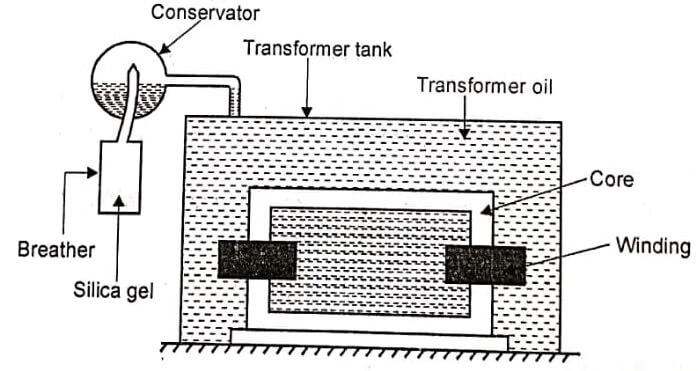

Expansion Tank or Conservator

A small auxiliary oil tank may be mounted above the transformer and connected to main tank by a pipe. Its function is to keep the transformer tank full of oil despite expansion or contraction of the coil with the changes in temperature. A small pipe connection between the gas space in the expansion tank, and the cover of the transformer tank permits the gas above the oil in the transformer to pass into the expansion tank, so that the transformer tank will be completely filled with oil.

Temperature Gauge

Every transformer is provided with a temperature gauge to indicate hot oil or hottest spot temperature. It is self contained weather proof unit made of alarm contacts. It is dial operated by bourdon gauge connected to a thermometer bulb located in the region of hottest oil.

Oil Gauge

Every transformer is fitted with an oil gauge to indicate the oil level present inside the tank. The oil gauge may be provided with an alarm contact which gives an alarm when the oil level has dropped beyond permissible height due to oil leak or due to any other reason.

Buchholz Relay

The first warning that a fault is present may be given by the presence of bubbles in the oil. If the transformer is fitted with a conservator and there are no pockets in which gas can collect, the gas bubbles will rise up the pipe joining the conservator to the tank. It is possible to mount gas operated relay in this pipe to give an alarm in case of minor fault and to disconnect the transformer from the supply mains in case of severe faults.

Breather

The simplest method to prevent the entry of the moisture inside the transformer tank is to provide chambers known as breather. The breather is filled with some drying agent, such as calcium chloride or silica gel. Silica gel or calcium chloride absorbs moisture and allows dry air to enter the transformer tank. The drying agent is replaced periodically as routine maintenance. The whole of the transformer tank and portion of conservator used is filled with oil. The breather is connected on one side of the conservator. Thus a small surface area of transformer oil is exposed to the atmosphere through the breather.

Bushings

Connections from the transformer windings are brought out by means of bushing. Ordinary porcelain insulators can be used upto a voltage of 33kV. Above 33kV, capacitor and oil filled type of bushings are used. Bushings are fixed on the transformer tank.

Cooling Arrangement in Transformers

The various methods of cooling employed in a transformer are

- Oil immersed natural cooled transformers

- Oil immersed forced air cooled transformers

- Oil immersed water cooled transformers

- Oil immersed forced oil cooled transformers

- Air blast transformers

Oil immersed Natural Cooled Transformers

In this type, the core and coils are immersed in insulating oil contained in an iron tank. The heat produced in the core and windings is conduct by the circulation of oil to the surface which dissipates heat to surroundings. In transformers of larger output, the dissipation surface is increased by providing large number of tubes on its sides. The oil not only keeps the windings cool but also provides additional insulation.

Oil Immersed Forced Air Cooled Transformers

In this type, the core and windings are immersed in oil and cooling is increased by forced air over the cooling surfaces. The air is forced over external surfaces such as tank, tubes and radiators by means of fan mounted external to the transformer.

Oil immersed Water Cooled Transformers

In this type, the core and windings are immersed in oil and cooling is increased by circulation of cold water through the tubes immersed in oil.

Oil immersed Forced Oil Cooled Transformers

In this type, the core and windings are immersed in oil and cooling is achieved by forced oil circulation. In this method of cooling forced oil circulation is obtained by a centrifugal pump which is located at either the oil inlet or outlet. The pump motor used for cooling is designed to operate totally immersed in the cooling oil being circulated.

Air Blast Transformers

Here the transformer is cooled by a forced circulation of air through core and windings.

It is used in substations located in thickly populated places where oil is considered a fire hazard. The air supplied is filtered to avoid dust entering the ventilating ducts.

[sc_fs_faq html=”true” headline=”h2″ img=”” question=”What is staggering in the construction of transformers?” img_alt=”” css_class=””] In transformer, the joints in the alternate layers are staggered in order to avoid the presence of narrow gaps right through the cross section of the core. [/sc_fs_faq]

| Read More Topics |

| Electrical and Mechanical Braking |

| Working principle of a transformer |

| Characteristics of DC Generator |