Even with the advent of AC motors and contemporary electronics, DC motors are still essential. The fact that they can provide steady torque and simple speed control makes them widely used, particularly in automation, EVs, and robots.

Construction of a DC Motor

Key Parts of a DC Motor

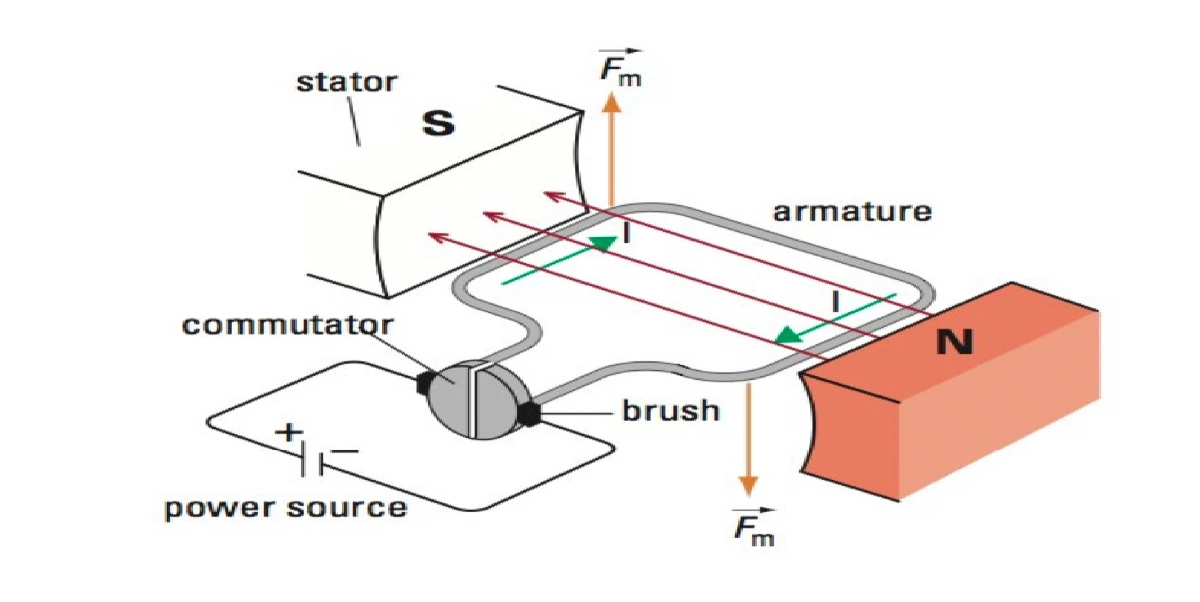

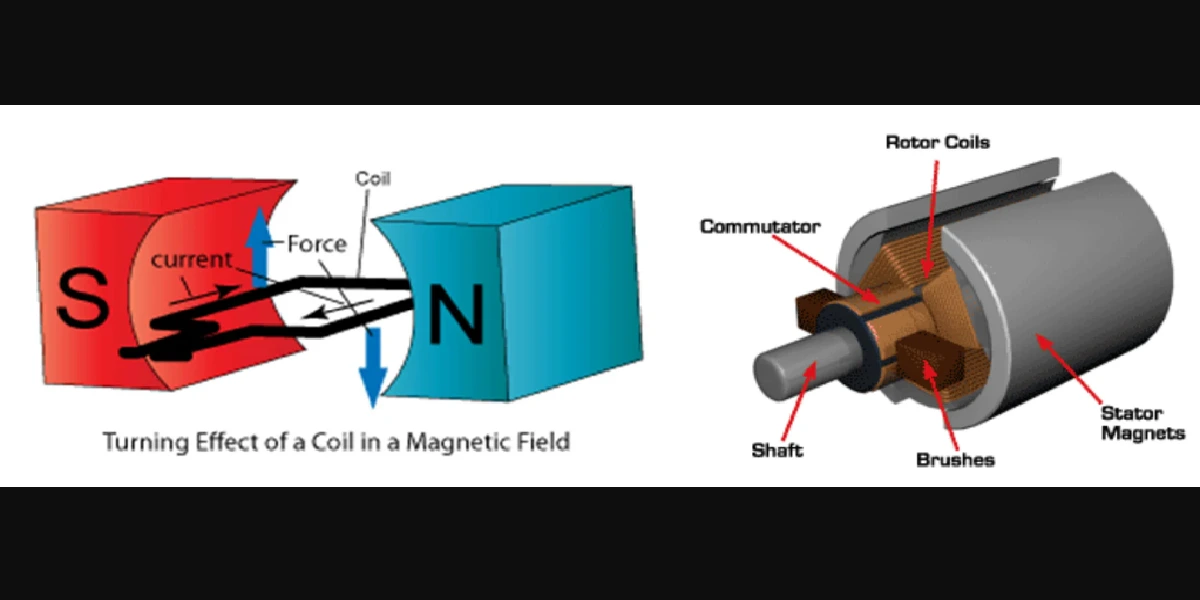

Stator

The fixed component of the motor, it supplies the magnetic field with windings or permanent magnets.

Rotor (Armature)

It’s the rotating component attached to the output shaft. It has windings through which the current passes.

Commutator

A split ring which reverses the current direction in the rotor coils, providing smooth rotation.

Brushes

Graphite or carbon blocks which carry the current from the power supply to the rotating commutator.

Field Windings or Permanent Magnets

They produce the magnetic field required for motion. Motors use windings (electromagnetic field) or permanent magnets for this.

Working Principle of DC Motors

The Electromagnetic Principle

DC motors are based on Fleming’s Left-Hand Rule. When a conductor carrying a current is positioned in a magnetic field, it develops a force that acts perpendicular to the current direction as well as the field.

How a DC Motor Converts Electricity into Motion

The armature winding, which is powered by DC current, interacts with the magnetic field. This results in torque, which rotates the rotor and hence drives a mechanical load such as a fan or wheel.

Types of DC Motors

There are various types of DC motors, each used for particular applications:

Separately Excited DC Motor

Field and armature windings supplied from independent sources.

Provides independent control of field flux and speed.

Shunt Wound DC Motor

Field windings in parallel to the armature.

Excellent speed control.

Series Wound DC Motor

Field windings series with armature.

Large amount of torque, but very poor speed control.

Compound Wound DC Motor

Has characteristics of both series and shunt.

Compromise between torque and speed control.

Permanent Magnet DC Motor

employs permanent magnets rather than field windings.

miniature and efficient; ubiquitous in handheld devices.

DC Motor Characteristics

Speed Control

The speed is directly proportional to voltage and inversely proportional to magnetic strength. This ensures that DC motors are simple to control through variable voltage or field weakening.

Torque and Efficiency

Torque = Armature Current × Magnetic Field Strength.

Large starting torque is a standout feature.

Applications of DC Motors

Industrial Applications

Applied in conveyors, rolling mills, and cranes because of their high starting torque.

DC Motors in Automobiles

DC motors are used in electric vehicles such as e-bikes and automobiles for effective power transmission and regenerative braking.

Application in Consumer Electronics

Used in fans, blowers, toys, and kitchen devices for dependable low-voltage operation.

Robotics and Automation

DC motors find application in robotics for their accurate speed and torque control.

Advantages and Disadvantages of DC Motors

Advantages:

Good speed control

High starting torque

Simple design

Easy to install

Disadvantages:

Maintenance (particularly brushes) needs to be done regularly

Less efficient than brushless types

Not suitable for high-voltage applications

Tips for Maintenance and Lifespan

Inspect and replace brushes periodically

Keep motor clean and dust-free

Lubricate bearings

Avoid overheating by adequate ventilation

Upcoming Trends for DC Motors (2025 and beyond)

Brushless DC Motors (BLDC) are supplanting conventional types in numerous fields with increased efficiency.

AI-based smart motors with automatic diagnosis capabilities are increasing in industrial applications.

Technological advancements in permanent magnet materials are enhancing torque output with size reduction.

Conclusion: DC motors are ageless engineering tools. From their basic design to intricate contemporary applications, they are constantly progressing while maintaining their fundamental benefits—reliability, control, and performance. If you are constructing a robot or powering an electric vehicle, there is likely a DC motor working hard behind the scenes.

Read also: How To Make Electrochemical Etching Stencils