Steam is an important medium for producing mechanical energy. A steam power plant continuously converts the energy stored in fossil fuels (coal, oil and natural gas). Steam has the advantage that it can be raised from water which is available in abundance. The steam power stations are very much suitable where coal is available in abundance. The pressure ranges from 10kg/cm² to super critical pressure and temperature varies from 250°C to 650°C.

Steam or thermal power plant is using steam as working fluid. Steam is produced in a boiler using coal as fuel and used to drive the prime mover (Steam turbine).

The heat energy is converted into mechanical energy by the steam turbine and that mechanical energy is used for generating power with the help of generator.

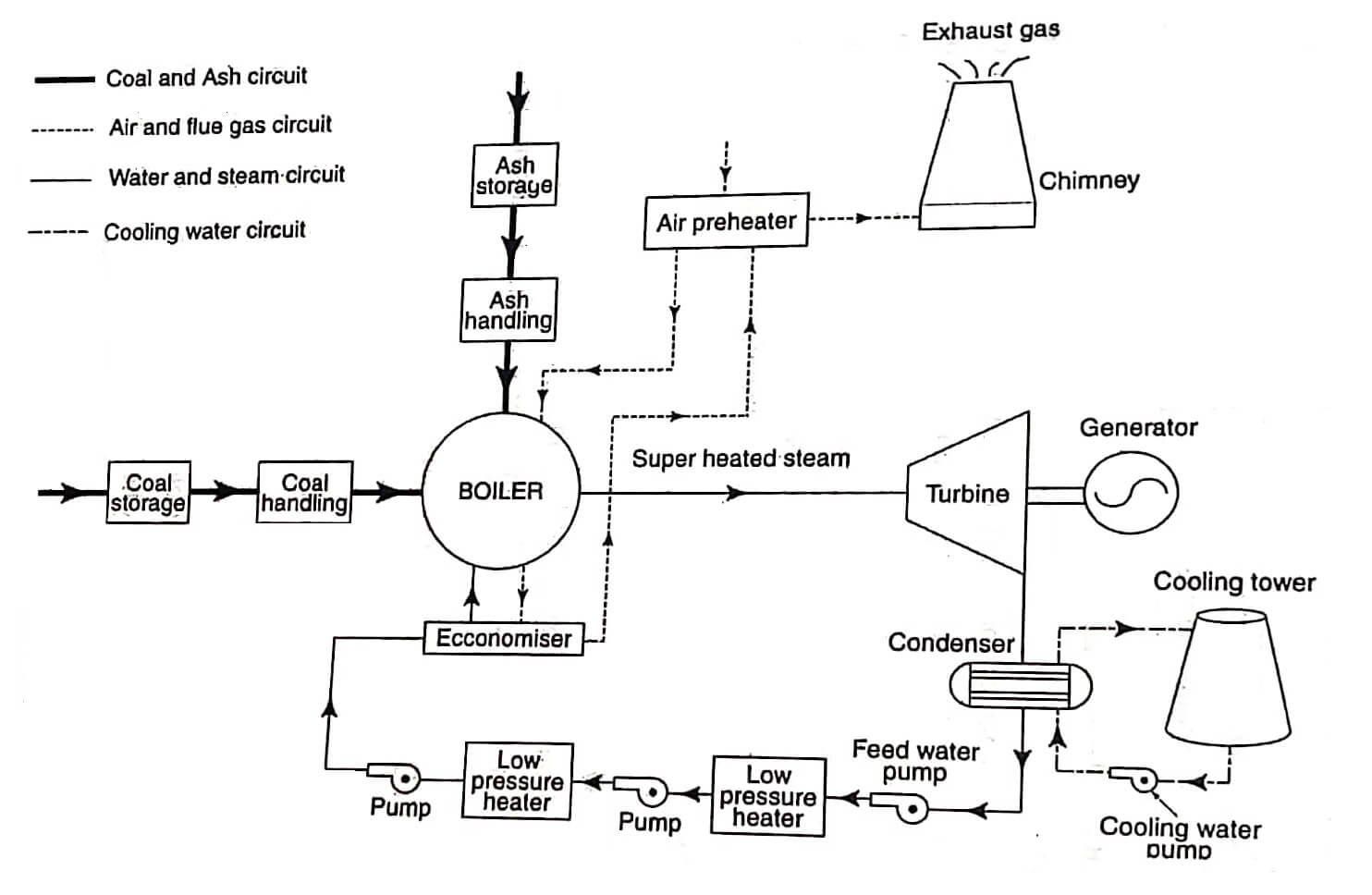

The layout of the steam power plant consists of four main circuits.

They are

- Coal and ash circuit.

- Air and flue gas circuit.

- Water and steam circuit.

- Cooling water circuit.

Coal and ash circuit

This circuit consists of coal storage, ash storage, coal handling and ash handling systems. The handling system consists of belt conveyors, screw conveyors etc. Coal from the storage yard is transferred to the boiler furnace by means of coal handling equipment. Ash resulting from the combustion of coal in the boiler furnace is removed to ash storage through ash handling.

The Indian coal contains 30 to 40% of ash and a power plant of 100MW produces normally 20 to 25 tones of hot ash per hour.

Air and flue gas circuit

This circuit consists of air filter, air preheater, dust collector and chimney. Air is taken from the atmosphere to the air preheater, the dust from the air is removed by means of using air filter. Then the waste heat of the flue gas is passed to the chimney for preheating the air in the preheater.

After combustion in the furnace, the flue gas which has sufficient quantity of heat is passed around the boiler tubes, dust collector, economiser and preheater before being exhausted to the atmosphere through the chimney. By passing the flue gas around the economiser and air preheater, the water and air are preheated before going to the boiler.

Feed water and steam circuit

This circuit consists of boiler feed pump, boiler, turbine, and feed heaters. The steam generated in the boiler passes through super heater and is supplied to the steam turbine. The steam is expanded in the steam turbine then passed to the condenser where it is condensed.

The condensate is heated in the HP and LP heaters using the steam tapped from different points of the turbine. The feed water is passing through the economiser, where it is further heated by means of flue gases. Using the economizer, the feed water is heated by the feed water heaters and then it is fed into the boiler.

Part of the steam and water are lost while passing through different components of the system. So, feed water is supplied from the external source to compensate losses.

Cooling water circuit

This circuit consists of circulating water pump, condenser, cooling water pumps and cooling tower. Abundant quantity of water is required for condensing the steam in the condenser. Adequate water, supply is available from various sources like river or lake. If adequate quantity of water is not available at plant sites, the warm water coming out from the condenser is cooled in cooling tower and it is recirculated again and again.

Characteristics of steam power plant

- Low cost as compared with hydro power plant.

- High efficiency.

- Reduced water requirement.

- Higher reliability and availability.

- Reduced environmental impact in terms of air pollution.

Advantages of steam power plant

- The power production does not depend on nature mercy.

- Initial investment is low.

- The power plant can be located near load center, so the transmission cost and losses are considerably reduced.

- The time requirement for construction and commissioning of thermal power plant require less period of time.

Disadvantages of steam power plant

- As compared with hydro-electric power plant, life and efficiency are less.

- Transportation of fuel is a major problem in this type of power plant.

- Power generation cost is considerably high when compared to hydro-electric plant.

- Air pollution is the major problem calling for additional investment.

- It cannot be used as peak load plant.

- The coal (fuel) needed may be exhausted by gradual use.

Steam Power Plant Cycles

What are all the steam power plant cycles?

The cycles which are used in the power plants are

- Rankine cycle

- Reheat cycle

- Regenerative cycle

- Reheat regenerative cycle

- Binary vapour cycle

- Superposed or topping cycle

- See More : Cooling towers and types

- See More : High Pressure boiler modern

- See More : Nuclear power plant

- See More : Hydro electric power plant