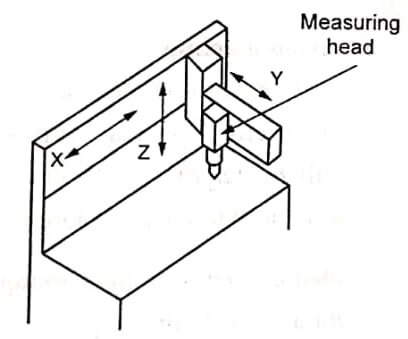

Coordinate measuring machine are used for the measurement of length over the outer surfaces of a length bar or any other long member. The member may be either rounded or flat and parallel. The measuring machine are more useful and advantages than vernier calipers, micrometer, screw gauges etc. The measuring machines are generally of more universal character and can be used for works of varied nature.

The coordinate measuring machine is used for contact inspection parts. When it is used for computer integrated manufacturing, the CMM are controlled by computer numerical control.

General software is provided for reverse engineering complex shaped objects. The measuring component is digitized by using CNC, the CMM and the component are then converted into a computer model which gives the two surface of the component. This advance in measuring machine is used for automatic work alignment on the table. The savings in inspection about 5 to 10 percent of the time is achieved on a CMM compared to manual inspection methods.

| Read More Topics |

| Controlling management process |

| Methods of measuring surface finish |

| Measurement of various elements |