Shape memory effect

It is the phenomenon in which the shape memory alloy apparently deforms at lower temperature and returns to its original shape (former shape) when heated at higher temperature.

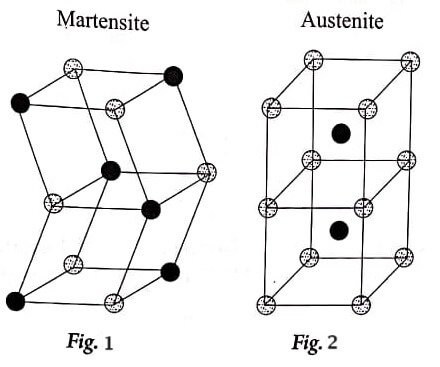

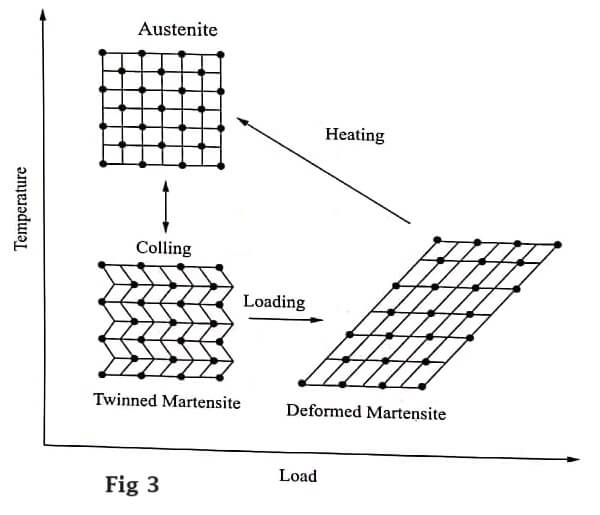

Let us consider a shape memory alloy for which the temperature is decreased. Due to decrease in temperature, phase transformation takes place from austenite to twinned martensite as shown in Fig. 3 (Process 1) i.e., a micro constituent transformation takes place from the needle structure (Austenite) to platelet like structure (Martensite).

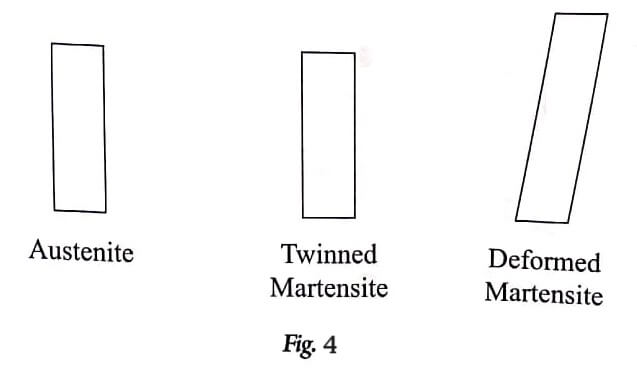

During this state the twinned martensite phase will have same size as that of austenite phase as shown in Fig. 1(macroscopic view). Hence, macroscopically if we see, no change in size (or) shape is visible between the austenite phase and twinned martensite phase of the SMA.

Both austenite and twinned matensite is stable in a particular range of temperature.

Now when the twinned martensite is applied a load, it goes to deformed martensite phase as indicated in Fig 3 (Process 2). During the transformation from twinned martensite to deformed martensite the change in shape and size occur both microscopically and macroscopically as shown in Fig 4.

Now when the material is further heated it will go from deformed martensite to austenite from (Process – 3) and the cycle continues as shown in Fig 3.

Pseudo-elasticity (or) Super elasticity

Pseudo-elasticity occur in some type of SMA in which the change in its shape will occur even without change in its temperature.

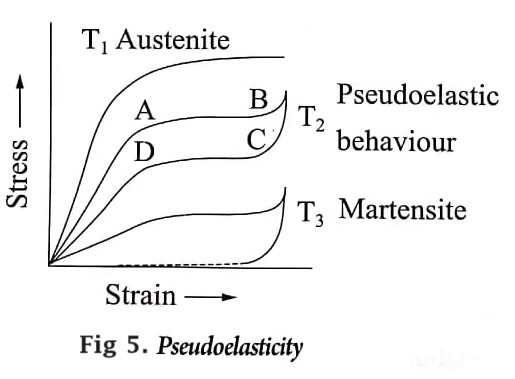

Pseudo-elasticity occurs in shape memory alloys when the alloy is completely composed of Austenite (temperature is greater than Af).

Unlike the shape memory effect, pseudo-elasticity occurs without a change in temperature.

The load on the shape memory alloy is increased until the austenite becomes transformed into martensite simply due to the loading. This process is shown in figure 5.

As soon as the loading is decreased the Martensite begins to transform back to Austenite since the temperature of the material is well above Af.

Here the shape recovery has not occurred by the application of heat but upon reduction of stress. This effect, which causes the material to be extremely elastic is known as pseudo-elasticity.

Hysteresis

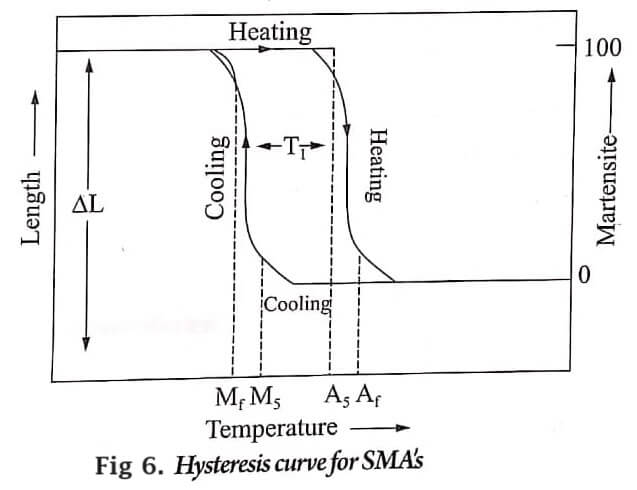

When a shape memory alloy is considered under constant tensile load for particular temperature range, the transformation of martensite to austenite occurs on heating and the reverse transformation occurs upon cooling. The difference between the transition temperature upon heating and cooling is called hysteresis. The hysteresis curve for shape memory alloys is shown in the figure 6.

The temperature range for the martensite to austenite transformation which takes place upon heating is somewhat higher than that for the reverse transformation upon cooling.

The difference between the transition temperatures upon heating and cooling is called Hysteresis. The hysteresis curve for SMAs is shown in Fig 6.

Hysteresis is generally defined as the difference between the temperature at which the material is 50% transformed to austenite upon heating and 50% transformed to martensite upon cooling. The difference can be up to 20−30°C.

| Read More Topics |

| Ferro-electricity and applications |

| Clausius mossotti equation |

| Polar and non-polar molecules |